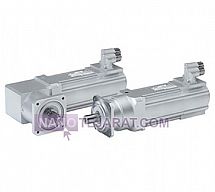

Electro gearbox

Electrogearboxes are among the most important industrial machinery used in industrial automation. The primary function of electrogearboxes is to reduce the input shaft speed from the motor and increase the output torque.

An electrogearbox is a type of power transmission system that combines an electric motor with a mechanical gearbox. This device is designed to convert electrical energy into rotational motion with adjustable torque and speed. In the structure of an electrogearbox, the electric motor is connected to a set of gears that optimize output speed and torque by changing gear ratios. This combination enables electrogearboxes to provide precise and reliable performance in industrial and automation applications. Typically, the electrogearbox housing is made of aluminum or durable steel to reduce weight while providing the necessary durability and resistance to environmental conditions.

From a technical perspective, electrogearboxes are produced in various types such as planetary epicyclic, helical, and worm gear, each with specific power transmission characteristics. These devices are usually equipped with automatic cooling and lubrication systems to ensure stable and long-term operation. Electrogearboxes offer the capability to adjust output speed through gear changes or motor speed control, providing versatility for use in a wide range of machinery and robots. Additionally, due to their compact and integrated structure, electrogearboxes are optimally designed for installation in limited spaces, enhancing efficiency and reducing energy consumption in industrial systems.

WATT scew bevel helical gearbox

MOTOVARIO B series helical gearbox

FLENDER helical gearbox

BONFIGLIOLI helical gearbox

Hollow shaft Varvel worm gearbox

Bonfiglioli helical hollow shaft gearbox

ATEX helical hollow shaft reducer

Hollow shaft BEVEL TANDLER gearbox

.jpg?width=215&height=192&cropratio=215:192&image=/admin/uploads/گیربکس-هالو-شافت-YILMAZ-ترکیه--YILMAZ-hollow-shaft-gearbox-بایگان-صنعت-امرداد-175-u2676-0a1c55-images (3).jpg&url=/admin/uploads/گیربکس-هالو-شافت-YILMAZ-ترکیه--YILMAZ-hollow-shaft-gearbox-بایگان-صنعت-امرداد-175-u2676-0a1c55-images (3).jpg)

YILMAZ hollow shaft gearbox

GX serie Rossi hollow shoft gearbox

SEW hollow shaft gearbox

Servotak planetary gearbox

DIEQUA aluminum body gearbox

KOFON Spiral bevel gear reducer

Zollent parallel shaft planetary gearbox

Jack up series Bonfiglioli planetary gearbox

Bonfiglioli concrete mixer planetary gearbox

Sumitomo coaxial planetary gearbox

GXA Parker gearbox

REDEX pinion shaft gearbox

JIE planetary gearbox

Wind turbine planetary gearbox

SMR extrusion hollow shaft gearbox

REDSUN hollow shaft gearbox

NGC mining planetary gearbox

VOGEL planetary gearbox

Reggiana solar gearbox

Bonfiglioli solar gearbox

Flender solar gearbox

Brevini solar gearbox

SEW solar gearbox

Behin Solar Gearbox

SITI solar gearbox

Shahbaz solar gearbox

Lenze solar gearbox

Alpha Solar Gearbox

Tramec servo motor solar gearbox

PGR solar gearbox

Bonfiglioli direct shaft gearbox

Motovario helical gearbox

Transtecno helical gearbox

SITI Helical Gearbox

Helical gearbox Rahnama

Pars Helical Gearbox

Iran Helical Gearbox

Helical gearbox Satisfied

Sharif Helical Gearbox

IMAK helical gearbox

PC Helical Gearbox

Lenze helical gearbox

Nord Helical Gearbox

STM helical gearbox

Oztekfen Helical Gearbox

AMG helical gearbox

SEW Germany direct shaft gearbox

Yilmaz direct shaft gearbox

Bonfiglioli Italy direct shaft gearbox

Motovario Italy direct shaft gearbox

Bonfiglioli Hanging Gearbox

Yilmaz Shaft-Mounted Gearbox

SEW Shaft Mounted Gearbox

Motovario Parallel Shaft Gearbox

SITI Parallel Shaft Gearbox

Lenze Parallel Shaft Gearbox

.jpeg?width=215&height=192&cropratio=215:192&image=/admin/uploads/گیربکس-آویز-نورد-آلمان-NORD-NORD-Parallel-Shaft-Gearbox-بایگان-صنعت-امرداد-175-u2676-70d15e-گیربکس آویز یا شافت موازی نورد آلمان (NORD).jpeg&url=/admin/uploads/گیربکس-آویز-نورد-آلمان-NORD-NORD-Parallel-Shaft-Gearbox-بایگان-صنعت-امرداد-175-u2676-70d15e-گیربکس آویز یا شافت موازی نورد آلمان (NORD).jpeg)

NORD Parallel Shaft Gearbox

STM Parallel Shaft Gearbox

IMAK Parallel Shaft Gearbox

Original Italian SITI Continuously Variable Transmission CVT Gearbox

Bonfiglioli Variable Speed Gearbox

Motovario Variable Speed Gearbox

SEW Variable Speed Gearbox – Made in Germany

STM Variable Speed Gearbox

Original SEW Vertical Gearbox from Germany

Motovario Vertical Gearbox from Italy

Flender Vertical Gearbox from Germany

Nord Germany Vertical Shaft Gearbox

Jacon Vertical Gearbox from India

Yilmaz Vertical Gearbox from Turkey

German SEW R Series Inline Helical Gearbox

SEW RF Series Direct Shaft Gearbox with Flange and Vertical Mounting

SEW RX Series Inline Shaft Gearbox

SEW RXF Series Inline Gearbox Made in Germany

.jpg?width=215&height=192&cropratio=215:192&image=/admin/uploads/گیربکس-عمود-کار-آلمانی-اس-ای-دبلیو-SEW-تیپ-K37-German-SEW-K37-Vertical-Gearbox-بایگان-صنعت-امرداد-175-u2676-0c594c-aw_10783_sew (1).jpg&url=/admin/uploads/گیربکس-عمود-کار-آلمانی-اس-ای-دبلیو-SEW-تیپ-K37-German-SEW-K37-Vertical-Gearbox-بایگان-صنعت-امرداد-175-u2676-0c594c-aw_10783_sew (1).jpg)

German SEW K37 Vertical Gearbox

.jpg?width=215&height=192&cropratio=215:192&image=/admin/uploads/گیربکس-عمود-کار-SEW-تیپ-K47-ساخت-آلمان-The-SEW-K47-vertical-gearbox--made-in-Germany-بایگان-صنعت-امرداد-175-u2676-aw_10783_sew (1).jpg&url=/admin/uploads/گیربکس-عمود-کار-SEW-تیپ-K47-ساخت-آلمان-The-SEW-K47-vertical-gearbox--made-in-Germany-بایگان-صنعت-امرداد-175-u2676-aw_10783_sew (1).jpg)

The SEW K47 vertical gearbox, made in Germany

SEW K67 Vertical Gearbox

SEW Vertical Shaft Gearbox Type K77

ROSSI PM250 gearbox

ROSSI PM350 gearbox

Rossi R Series worm gearbox

Rossi MR Series worm gearbox

Rossi EP Series planetary gearbox

Rossi GX-G Series bevel helical right-angle gearbox

Rossi H Series helical gearbox, manufactured in Italy

Rossi R-MR Series Worm Gearbox

ROSSI A Series worm gearbox

ROSSI AS Series worm gearbox

ROSSI M Series worm gearbox

ROSSI E Series helical inline gearbox

ROSSI ES Series helical inline gearbox

ROSSI EP Series planetary gearbox

Yilmaz V Series Planetary Gearbox Coupled with Motor and Flange

Yilmaz KR Bevel Right-Angle Gearbox with Hollow Shaft Output

YILMAZ P Series planetary gearbox

YILMAZ WORM gearbox series E

YILMAZ WORM gearbox series ET

YILMAZ WORM gearbox series EV

YILMAZ helical inline gearbox series N

YILMAZ helical inline gearbox series M

YILMAZ parallel shaft suspended gearbox series D

YILMAZ crankshaft side-shaft gearbox series K

BONFIGLIOLI right-angle shaft gearbox

BONFIGLIOLI worm gearbox series VF/W

Bonfiglioli bevel pinion gearbox

Bonfiglioli bevel gearbox series A

Bonfiglioli TA parallel shaft gearbox

Bonfiglioli variable speed gearbox series V 0.25

Bonfiglioli variable speed gearbox series V 0.5

Bonfiglioli variable speed gearbox series V1

YILMAZ M series helical gearbox

YILMAZ K series bevel gearbox

YILMAZ PF series planetary gearbox

YILMAZ T series hanging gearbox

YILMAZ B series heavy-duty gearbox

YILMAZ H series heavy-duty gearbox

YILMAZ KR series side-shaft gearbox