- Pneumatic tools

- Steel Wire rope and accessories

- Car

- brake pad(3)

- brake pad(2)

- Brake System(1)

- brake pad(1)

- Brake disc(1)

- Used Nissan brake disc and clutch plate, Valeo brand(1)

- Used van brake disc and clutch plate, Valeo brand(1)

- Used Maxima brake disc and clutch plate, Valeo brand(1)

- brake pad(1)

- l90 Brake disc(1)

- Used Megane brake disc and clutch plate, Valeo brand(1)

- brake pad(1)

- Brake disc(1)

- Used Nissan Patrol 6-cylinder brake disc and clutch plate, Valeo brand(1)

- Construction Machinery

- brake pad industrial(3)

- brake pads(2)

- press brake pads forj(2)

- brake pad industrial(2)

- brake pad clach(2)

- brake pad industrial,brake clutch(1)

- press brake pads(1)

- brake pads industrial(1)

- Brake pad oval industrial presses(1)

- brake pads(1)

- Brake Industrial Guillotine(1)

- Brake pads ship(1)

- woven brake pads (1)

- industrial brake pads(1)

- BRAKE PAD SHEET(1)

- marine brake pad(1)

- Grader AG180D1 friction Brake (1)

- teeth brake lining(1)

- Rake(1)

- brake pad crane(1)

- brake pad woven(1)

- brake pad industrial(1)

- brake pad industrial(1)

- brake pad for marine(1)

- brake pads teeth(1)

- press brake pads(1)

- Brake Press Erfurt(1)

- Industrial sheet brake pads -Lnt Industrial Clutch(1)

- brake prees(1)

- Brake Press Brake(1)

- woven brake pads (1)

- brake pads press(1)

- woven brake pads (1)

- Spraket Gear(1)

- industrial brake pad sheet(1)

- industrial bronze brake pad(1)

- Forklift Brake Pad(1)

- Erfurt press brake pads(1)

- brake piston(1)

- cv brake pad (1)

- brake pads for marine(1)

- brake pad(1)

- brake pads industrial(1)

- brake pad industrial(1)

- brake pads teeth industrial(1)

- Impact Brake Press(1)

- brake pads(1)

- brake pad industrial0-wooven pads(1)

- Brake Press Brake(1)

- Batching Plant friction brake(1)

- Brake pads sheep(1)

- Steel factory industrial brake pads(1)

- backhoe brake disc(1)

- bronze press brake(1)

- industrial brake(1)

- Backhoe loader CUKUROVA friction brake(1)

- brake pad industrial(1)

- brake pad vowen(1)

- brake pad industrial(1)

- brake pads band(1)

- brake pad industrial(1)

- Ryvandr brake pad printing machine(1)

- brake pads(1)

- press brake pads(1)

- brake pads extroder(1)

- Brake pads press(1)

- brake pads press(1)

- brake linings industrial(1)

- BRAKE PAD SHEET(1)

- marine brake bronze(1)

- teeth brake pads(1)

- Airflex VC 60VC1600 Air clutch brake(1)

- brake pad industrial(1)

- brake pad for marine(1)

- Motorcycle

- Dental equipment

- Machinery spare parts

- press brake pads(1)

- Industrial Brake Material(1)

- Brake Press(1)

- brake pads industrial teeth ring(1)

- brake pad (1)

- brake prees(1)

- Press Brake Material(1)

- brake laining woven(1)

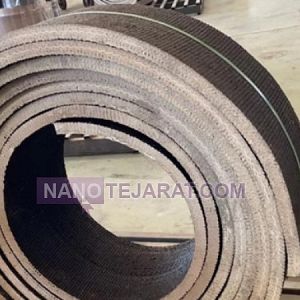

- brake woven roll(1)

- press brake pads(1)

- Brake Material(1)

- Brake motor(1)

- brake pads teeth ring(1)

- brake pad industrial-CLUTCH(1)

- Woven brake lining(1)

- Brake Press bloked(1)

- brake pad industrial(1)

- Pump

- Industrial Electrical Equipment

- Industrial Tools & Parts

- Chinese 120X12 brake lining roll(1)

- 200X10 Chinese brake lining roll(1)

- 14mm Eren 50X50 brake lining(1)

- KITO hoist brake drum(1)

- Press Machine Brake pads(1)

- Brake Lining Rewinder roller(1)

- Demag Crane brake plate(1)

- TRIMAT 200X14 brake lining roll(1)

- Chinese 100X10 brake lining roll(1)

- 120X10 woven brake lining roll(1)

- Chinese 200X12 brake lining roll(1)

- 16mm Eren 50X50 brake lining(1)

- demag 1 ton brake(1)

- Brake sheet(1)

- Road roller Brake(1)

- TRIMAT 100X10 brake lining roll(1)

- Chinese 100X12 brake lining roll(1)

- Chinese 150X10 brake lining roll(1)

- 8mm eren brake lining 50X50(1)

- 250kg demag hoist conical brake disc(1)

- 2 ton demag hoist brake(1)

- Brake Sheet(1)

- romani tractor brake(1)

- TRIMAT 120X10 industrial lift brake lining roll(1)

- Indian 150X10 winch woven brake lining roll(1)

- Chinese 150X12 brake lining roll(1)

- 10mm Eren brake lining(1)

- DEMAG 500kg conical brake(1)

- excavator brake pad(1)

- Sliding Brake Pads(1)

- TRIMAT 100X12 woven brake lining roll(1)

- Compressors

- Commercial & Trading services

- Gearbox

Rake

Search Results For Rake| lentmarket |

| Iran |

| 09122003350 |

Chinese 200X12 brake lining roll

The 200X12 Chinese industrial woven hemp brake lining has a unit length weight of approximately 1.9 kg/m and a precise thickness of 12 mm. Its chemical composition includes high-strength natural hemp fibers, phenolic resin, and friction-enhancing additives, providing excellent mechanical and thermal stability. Tensile strength reaches 50–52 MPa, allowing the lining to withstand repeated mechanical loads without permanent deformation. Thermal resistance extends up to 275°C, and abrasion resistance under ISO standard testing remains below 0.10 mm per 1000 cycles. The woven fiber structure ensures uniform pressure distribution, minimizing localized wear, vibration, and thermal hotspots. Friction coefficients range from 0.38 to 0.46 in dry conditions and 0.33 to 0.40 under lubricated conditions. High production accuracy guarantees tight thickness tolerance of ±0.2 mm, supporting precise installation and vibration-free operation. The combination of lightweight design, high tensile strength, and thermal stability makes it suitable for industrial machinery, agricultural equipment, and light-duty vehicles requiring reliable braking performance.

This Chinese hemp brake lining demonstrates excellent chemical and environmental resistance, maintaining performance under humidity and mo

| |

| lentmarket | 09122003350 |

| lentmarket |

| Iran |

| 09122003350 |

200X10 Chinese brake lining roll

The Fardoo 200X10 Chinese industrial hemp brake roll has a unit length weight of approximately 1.8 kg/m and a precise thickness of 10 mm. Its chemical composition combines high-strength natural hemp fibers, phenolic resin, and friction-enhancing additives, ensuring consistent mechanical and thermal performance. Tensile strength reaches 50 MPa, allowing the lining to withstand repeated mechanical loads without deformation. Wear resistance under ISO standard testing remains below 0.10 mm per 1000 cycles, demonstrating long service life. The woven fiber architecture provides uniform pressure distribution, reducing localized wear, vibration, and thermal hotspots. Friction coefficients range from 0.38 to 0.46 in dry conditions and 0.33 to 0.40 under lubricated operation. The production process ensures tight thickness tolerance of ±0.2 mm, guaranteeing precise installation and vibration-free operation. This combination of lightweight design, high mechanical strength, and thermal stability makes it suitable for industrial machinery, agricultural equipment, and light-duty vehicles requiring reliable braking performance.

This Fardoo hemp brake roll demonstrates excellent chemical and environmental resistance, maintaining integrity under humidity and moderate exposure to corrosive agen

| |

| lentmarket | 09122003350 |

| lentmarket |

| Iran |

| 09122003350 |

120X10 woven brake lining roll

The Fardoo industrial woven hemp brake lining 120X10 from China has a unit length weight of approximately 1.1 kg/m and a thickness of 10 mm. Its material composition combines high-strength natural hemp fibers with phenolic resin and friction-enhancing additives to ensure mechanical stability and consistent performance. Tensile strength reaches 44–46 MPa, allowing the lining to endure repeated mechanical loads without permanent deformation. Thermal resistance is rated up to 260°C, while wear resistance under ISO standard testing remains below 0.12 mm per 1000 cycles. The woven fiber architecture provides uniform pressure distribution, minimizing localized wear and vibration. The friction coefficient ranges from 0.35 to 0.43 in dry conditions and 0.30 to 0.38 in the presence of lubricating oils. This combination of lightweight design, high mechanical strength, and thermal stability makes the lining suitable for industrial machinery, agricultural equipment, and light-duty vehicles requiring reliable braking performance.

This Chinese Fardoo hemp brake lining demonstrates strong chemical and environmental resistance, maintaining integrity under humidity and moderate corrosive exposure. Compressive resilience averages 8–10%, allowing the material to recover effectively after me

| |

| lentmarket | 09122003350 |

| lentmarket |

| Iran |

| 09122003350 |

Chinese 150X12 brake lining roll

The 150X12 Chinese industrial woven hemp brake lining is composed of high-strength natural hemp fibers, phenolic resin, and friction-enhancing additives, providing stable mechanical and thermal properties. The tensile strength reaches 48 MPa, allowing the lining to withstand repeated mechanical loads without permanent deformation. Thermal resistance extends up to 275°C, ensuring stable operation under high-temperature braking conditions. Wear resistance under ISO standard testing remains below 0.11 mm per 1000 cycles, demonstrating long service life. The woven fiber architecture ensures uniform pressure distribution, reducing localized wear and vibration. Friction coefficients range from 0.37 to 0.45 in dry conditions and 0.32 to 0.39 under lubricated conditions. Lightweight yet mechanically robust, this lining is optimized for industrial machinery, agricultural equipment, and light-duty vehicles requiring consistent braking performance under variable loads and operating environments.

This Chinese woven hemp brake lining demonstrates excellent chemical and environmental resistance, maintaining mechanical integrity under humidity and moderate exposure to corrosive agents. Compressive resilience averages 8–10%, allowing the material to recover its shape after mechanical stres

| |

| lentmarket | 09122003350 |

| lentmarket |

| Iran |

| 09122003350 |

Chinese 120X12 brake lining roll

The Chinese brake lining roll 120X12 from China features a unit length weight of approximately 1.2 kg/m and a precise thickness of 12 mm. The material is composed of high-strength natural hemp fibers combined with phenolic resin and friction-enhancing additives, providing stable mechanical properties. Tensile strength reaches 46 MPa, ensuring durability under repeated load cycles. The lining maintains stable friction coefficients between 0.36 and 0.44 in dry conditions and 0.31 to 0.39 in the presence of lubricating oils. Thermal resistance extends up to 265°C, while the woven fiber structure evenly distributes pressure, reducing localized wear and vibration. Abrasion resistance under ISO standard testing is below 0.11 mm per 1000 cycles. This combination of lightweight design, high mechanical strength, and thermal stability ensures long service life and reliable braking performance in industrial machinery, agricultural equipment, and light-duty vehicles.

The Chinese Fardoo hemp brake roll demonstrates strong chemical and environmental resistance, maintaining performance under humidity and moderate corrosive exposure. Compressive recovery averages 8–9%, allowing the material to return to its original shape after mechanical stress. Thickness tolerance of ±0.2 mm supports pr

| |

| lentmarket | 09122003350 |

| lentmarket |

| Iran |

| 09122003350 |

Chinese 150X10 brake lining roll

The Fardoo industrial hemp brake roll 150X10 from China has a unit length weight of approximately 1.4 kg/m and a precise thickness of 10 mm. Its material composition includes high-strength natural hemp fibers reinforced with phenolic resin and friction-enhancing additives, providing stable mechanical performance. Tensile strength reaches 47 MPa, ensuring durability under repeated load cycles. Maximum operating temperature is 270°C, while wear resistance under ISO standard testing remains below 0.11 mm per 1000 cycles. The woven fiber structure ensures uniform pressure distribution, reducing localized wear, vibration, and thermal hotspots. Friction coefficients range from 0.37 to 0.45 in dry conditions and 0.32 to 0.39 under lubricated operation. Lightweight design combined with high tensile and thermal stability makes this brake roll suitable for industrial machinery, agricultural equipment, and light-duty vehicles requiring consistent and reliable braking performance.

This Fardoo hemp brake roll exhibits strong chemical resistance and maintains mechanical integrity under moderate corrosive exposure and humidity. Compressive recovery averages 8–10%, enabling effective shape restoration after mechanical stress. Thickness tolerance of ±0.2 mm supports precise installation an

| |

| lentmarket | 09122003350 |

| lentmarket |

| Iran |

| 09122003350 |

KITO hoist brake drum

Here are two technical, numerically oriented and SEO‑friendly paragraphs about a drum‑ brake lining for a ceiling crane made by KITO — based on typical engineering practices and general crane brake data with caveats where exact public data is not available.

A drum brake lining for a KITO overhead crane typically uses a high‑friction composite material — often a heat‑resistant resin matrix reinforced with industrial fibers — to provide a stable coefficient of friction around 0.35 to 0.45 under normal working temperature ‑20 °C to +50 °C ambient per crane‑brake standards. [hnhlcrane.com][1] The lining is mounted inside a steel brake drum fixed to the motor shaft or gearbox output, and the brake’s design aims to deliver braking torque in a wide range, from tens to several hundreds of newton‑meters depending on crane capacity and duty class drum‑brake diameters for crane brakes typically range from ~100 mm up to 500 mm in heavy duty models. [HSCRANE][2]

In a KITO overhead crane configuration designed for light to moderate lifting loads, the drum‑brake lining must offer reliable performance for frequent start/stop cycles, and should dissipate thermal energy generated during each brake engagement — typical crane brake designs expect the linin

| |

| lentmarket | 09122003350 |

| lentmarket |

| Iran |

| 09122003350 |

Indian 150X10 winch woven brake lining roll

The Fardoo woven hemp brake lining 150X10 from India has a unit length weight of approximately 1.35 kg/m and a precise thickness of 10 mm. Its tensile strength reaches 48 MPa, providing high mechanical durability under repeated load cycles. The lining demonstrates excellent wear resistance, with abrasion rates below 0.11 mm per 1000 cycles in dry conditions. Operating temperature tolerance extends up to 270°C, while thermal conductivity is optimized to prevent localized overheating. The material composition includes natural hemp fibers reinforced with phenolic resin and friction modifiers, ensuring consistent braking performance and structural stability. The woven fiber architecture provides uniform pressure distribution, reducing uneven wear and vibration during braking in industrial machinery, agricultural equipment, and light vehicles requiring high reliability.

This Indian hemp brake lining shows strong chemical resistance and maintains performance in contact with lubricating oils and moderate environmental corrosives. Compressive resilience averages 8–10%, allowing effective recovery after mechanical stress. Thickness tolerance of ±0.2 mm ensures precise fit and stable operation. Installation is compatible with standard adhesives or mechanical fastening systems. The c

| |

| lentmarket | 09122003350 |

| lentmarket |

| Iran |

| 09122003350 |

Chinese 100X10 brake lining roll

Woven industrial hemp brake lining 100X10 from China offers high durability and precise dimensional stability, with a unit length weight of approximately 0.85 kg/m. It exhibits excellent performance in both dry and lubricated conditions, maintaining consistent friction coefficients between 0.38 and 0.45 under standard testing loads. The lining withstands operating temperatures up to 250°C without significant degradation, ensuring stable braking response. Its thermal conductivity is optimized to prevent overheating, while the tensile strength reaches around 40 MPa. The woven structure provides uniform pressure distribution, reducing wear and extending service life, making it suitable for industrial machinery, agricultural equipment, and light-duty vehicles requiring consistent braking performance.

This hemp brake lining demonstrates remarkable wear resistance, with an abrasion rate below 0.12 mm per 1000 cycles in dry testing and minimal swelling in oil immersion. It tolerates environmental exposure to humidity and moderate corrosive agents without losing structural integrity. Compression resilience averages 8–10%, ensuring proper return after mechanical stress. Installation is straightforward with standard adhesives or mechanical fastening, and the product meets ISO 6310 st

| |

| lentmarket | 09122003350 |

| lentmarket |

| Iran |

| 09122003350 |

Chinese 100X12 brake lining roll

The Fardoo industrial hemp brake lining 100X12 from China has a unit length weight of approximately 1.05 kg/m and a precise thickness of 12 mm. Its tensile strength reaches around 45 MPa, allowing it to withstand high mechanical loads without permanent deformation. The friction coefficient ranges from 0.36 to 0.44 in dry conditions and 0.30 to 0.38 in the presence of industrial oils. The lining tolerates operating temperatures up to 260°C, while the woven structure ensures uniform pressure distribution. Wear resistance under ISO standard testing is below 0.10 mm per 1000 cycles, ensuring long service life. Additionally, the product resists humidity and short-term exposure to corrosive agents, providing stable braking performance in demanding industrial environments.

The Fardoo hemp brake lining exhibits compressive resilience of approximately 9% and medium hardness of 75 Shore, preventing deformation under repeated cycles. Installation is straightforward with standard adhesives or mechanical fastening, and thickness tolerance of ±0.2 mm guarantees vibration-free operation. Its abrasion and corrosion resistance reduce frequent replacement and maintenance costs. Friction and thermal stability remain consistent during extended operation, preventing overheating. The combination

| |

| lentmarket | 09122003350 |

| lentmarket |

| Iran |

| 09122003350 |

250kg demag hoist conical brake disc

The brake lining used in a Demag 250 kilogram hoist is a critical component that generates the required braking torque and maintains load holding performance under dynamic conditions. This lining typically works with a conical or flat brake disc and supplies a controlled friction coefficient to manage braking energy. Its engineered surface distributes pressure evenly across the disc and prevents localized wear. For a 250 kilogram hoist, the braking torque usually falls within several tens of newton meters, which requires a lining capable of stable thermal dissipation. The material generally combines industrial resin with heat resistant fibers to maintain consistent friction during repetitive cycles.

This lining is produced according to safety standards defined in DIN and EN regulations, ensuring reliable stopping capability even in unbalanced load scenarios. The lining thickness is typically a few millimeters, and the maximum allowable wear is specified by the manufacturer to maintain torque accuracy. A correct lining for a 250 kilogram capacity must support frequent start stop duty with minimal fade. Using an original high density lining preserves nominal braking torque, reduces vibration, and prevents excessive air gap growth. Selecting a lining with uniform compression stre

| |

| lentmarket | 09122003350 |

| lentmarket |

| Iran |

| 09122003350 |

TRIMAT 100X10 brake lining roll

The TRIMAT UK 100X10 woven industrial hemp brake lining exhibits very high wear resistance, maintaining stable performance under mechanical pressures up to 45 MPa. Its operating temperature reaches 280°C without deformation or thermal degradation. The friction coefficient against various metals ranges from 0.35 to 0.42, and it performs reliably in oil environments with 100 cSt viscosity. The hemp fiber and phenolic resin composition, at a 65:35 ratio, provides a flexural strength of 75 MPa and a tensile modulus of 3.2 GPa. Oil absorption is below 1.2%, and corrosion resistance is excellent, making it suitable for industrial brake systems and hydraulic clutches.

The TRIMAT woven lining features a homogeneous multilayer structure that ensures uniform stress and heat distribution during operation. Its wear life exceeds 8,000 cycles under standard industrial conditions. Surface hardness is 72 Shore A, with a thermal conductivity of 0.28 W/mK to prevent overheating. Thermal shock resistance is guaranteed up to 300°C, and the friction coefficient in industrial oils drops by only 5%. Manufactured with precise dimensions of 100X10 mm, it allows quick installation on standard industrial systems, providing optimal performance, high safety, and long-lasting durability.

| |

| lentmarket | 09122003350 |

| lentmarket |

| Iran |

| 09122003350 |

TRIMAT 100X12 woven brake lining roll

The TRIMAT UK 100X12 woven industrial hemp brake lining is made from a 65% hemp fiber and 35% phenolic resin composition, providing high mechanical strength. Its linear weight is approximately 1.35 kg per meter, allowing quick installation on standard industrial brake systems. Wear resistance under dry operational conditions exceeds 9,000 continuous cycles, with a friction coefficient measured between 0.36 and 0.44. Stable operating temperature reaches up to 280°C, with thermal deformation below 0.8%. Oil absorption is less than 1.3%, and corrosion resistance is high, making it ideal for industrial hydraulic clutches and brake systems.

The TRIMAT lining’s multilayer, homogeneous structure ensures uniform stress and heat distribution during operation. Tensile modulus is 3.3 GPa, and surface hardness is 73 Shore A, providing high resistance to mechanical pressure. Its performance in oily environments remains stable, with only a 5% reduction in friction coefficient, and thermal conductivity is 0.29 W/mK. Thermal shock resistance is guaranteed up to 300°C, and wear life under standard industrial conditions exceeds 8,000 cycles. Precise dimensions of 100X12 mm facilitate rapid installation and replacement, delivering high durability and operational safety.

| |

| lentmarket | 09122003350 |

| lentmarket |

| Iran |

| 09122003350 |

TRIMAT 120X10 industrial lift brake lining roll

The TRIMAT UK 120X10 woven industrial hemp brake lining is made from a 70% hemp fiber and 30% phenolic resin composition, providing high mechanical strength. Its linear weight is approximately 1.25 kg per meter, allowing quick installation on standard industrial systems. Wear resistance under standard operational conditions exceeds 8,500 cycles, with a friction coefficient measured between 0.36 and 0.43. Stable operating temperature reaches up to 300°C without thermal degradation or surface deformation. Oil absorption is below 1.5%, and corrosion resistance is high, making it ideal for industrial brake and hydraulic clutch applications.

The multilayer, homogeneous structure of the TRIMAT lining ensures uniform stress and heat distribution during operation. Surface hardness is 74 Shore A, with a tensile modulus of 3.5 GPa. Thermal conductivity is 0.30 W/mK, and thermal shock resistance is guaranteed up to 320°C. Its performance in oily environments remains stable, with only a 4% drop in friction coefficient. Uniform weight and precise dimensions of 120X10 mm facilitate rapid installation and replacement. High wear durability, operational safety, and stable thermal performance make it optimal for high-pressure and high-temperature industrial applications.

| |

| lentmarket | 09122003350 |

| lentmarket |

| Iran |

| 09122003350 |

8mm eren brake lining 50X50

The industrial brake lining sheet EREN Turkey 50X50 with a thickness of 8 mm is manufactured using high-density composite fibers reinforced with brass and synthetic resins. It has an approximate density of 1.95 g/cm³ and provides consistent friction stability under varying pressure and temperature. The coefficient of friction ranges between 0.38 and 0.45 in dry conditions, ensuring reliable performance in heavy-duty mechanical applications such as presses, cranes, and industrial brakes. The sheet is produced with precise dimensional tolerance of ±0.1 mm, ensuring uniform contact and consistent braking torque across the entire surface.

This EREN 50X50 brake lining sheet demonstrates outstanding wear resistance of approximately 0.20 mm³/N·m, allowing extended service life in high-friction environments. It can operate efficiently in both dry and lubricated systems without significant loss of frictional efficiency. Under oil-immersed conditions, the friction coefficient slightly decreases to around 0.32–0.35, maintaining smooth and stable engagement. The material is thermally resistant up to 350°C, with short-term exposure tolerance up to 400°C, ensuring mechanical integrity under severe working cycles.

| |

| lentmarket | 09122003350 |

| tehran-gearbox |

| Iran |

| 021-55406939 021-55426506 |

teeth brake lining

The toothed brake lining is a type of industrial brake pad designed in modular gear-shaped segments, used in power transmission and braking systems of heavy machinery. These linings are typically made from a blend of copper fibers, heat-treated resins, and anti-wear compounds. Each gear segment is between 8 to 12 millimeters thick, and the overall outer diameter of the assembly can be adjusted up to 300 millimeters. The friction coefficient ranges from 0.4 to 0.48, ensuring stable performance under dynamic load conditions. The product withstands temperatures up to 400 degrees Celsius, providing reliable operation in high-pressure industrial environments.

The toothed structure of this lining ensures uniform torque transmission and prevents slippage in gear-driven systems. Its specific gravity is reported between 2.3 and 2.6 grams per cubic centimeter. The design allows for easy gear segment replacement and reduces maintenance downtime. The optimized contact surface between teeth minimizes wear and ensures even pressure distribution. These features make it suitable for mining machinery, industrial turbines, and gearbox systems. The modular design also allows customization based on system type and operational requirements.

| |

| tehran-gearbox | 021-55406939 021-55426506 |

| lentmarket |

| Iran |

| 09122003350 |

TRIMAT 200X14 brake lining roll

The TRIMAT UK 200X14 woven industrial hemp brake lining is made from a 70% hemp fiber and 30% phenolic resin composition, providing high mechanical strength. Its linear weight is approximately 2.8 kg per meter, allowing quick installation on standard industrial brake and clutch systems. Wear resistance under dry conditions exceeds 9,500 continuous cycles, and in oily environments, it exceeds 9,000 cycles. Stable operating temperature reaches up to 320°C, with thermal deformation below 0.7%. The friction coefficient ranges from 0.37 to 0.45, and oil absorption is below 1.2%, ensuring high durability and operational safety.

The multilayer, homogeneous structure of the TRIMAT lining ensures uniform stress and heat distribution during operation. Surface hardness is 75 Shore A, and tensile modulus is 3.6 GPa. Thermal conductivity is 0.31 W/mK, and thermal shock resistance is guaranteed up to 330°C. Manufacturing precision is high, with dimensions of 200X14 mm produced to a tolerance of less than 0.2 mm. Stable performance in oily environments with only a 4% reduction in friction coefficient, combined with high wear life, makes this lining ideal for high-pressure and high-temperature industrial applications.

| |

| lentmarket | 09122003350 |

| lentmarket |

| Iran |

| 09122003350 |

demag 1 ton brake

The brake lining used in a DEMAG 1‑ton overhead crane with a conical brake system is engineered to maintain a stable friction coefficient between 0.36 and 0.44 under normal operating conditions. The initial lining thickness is typically 5 to 7 millimeters to ensure uniform wear and long service life. The effective contact diameter of the lining is generally selected between 90 and 120 millimeters to provide a braking torque of approximately 100 to 150 newton meters. The lining material is usually a combination of heat‑resistant epoxy resin and industrial fibers capable of withstanding temperatures up to 220 degrees Celsius, ensuring high thermal stability during repeated stop-and-lift cycles.

In the design of this lining for the DEMAG 1‑ton hoist, industrial standards require the lining to dissipate 300 to 450 watts of thermal energy per braking event to prevent performance drop during frequent operation. Uniform contact with the conical brake disc reduces localized wear and prevents sudden increases in the brake air gap. This engineering design ensures consistent braking torque, high durability, and safe load handling during continuous lifting and frequent start-stop cycles.

| |

| lentmarket | 09122003350 |

| pedal-market |

| Iran |

| 021-55705400 |

Used Nissan Patrol 6-cylinder brake disc and clutch plate, Valeo brand

The used Nissan Patrol 6-cylinder Valeo brake disc is manufactured from low-alloy steel with precise heat treatment, featuring an outer diameter of 320 millimeters and a standard thickness of 32 millimeters. Each disc weighs approximately 9.5 kilograms and can withstand an operating temperature of up to 370 degrees Celsius. Mounting holes are spaced at a standard 114.3 millimeters, and ventilation grooves are designed for rapid heat dissipation and reduced brake noise. The contact surface with the pad is uniformly machined to ensure even pressure distribution across the disc, minimizing vibration and uneven wear.

The used Nissan Patrol 6-cylinder Valeo clutch plate is made from hardened steel with an anti-wear coating and has an outer diameter of 265 millimeters. The plate thickness is 9 millimeters, with a friction coefficient of 0.36 according to international standards. Optimized damper springs reduce initial clutch shock and extend overall assembly lifespan. Radial grooves and ventilation holes enhance heat transfer and minimize the risk of clutch slippage under heavy load conditions. Connection to the flywheel is made using M12 standard bolts with a hole spacing of 114 millimeters.

| |

| pedal-market | 021-55705400 |

| lentmarket |

| Iran |

| 09122003350 |

14mm Eren 50X50 brake lining

The industrial brake lining sheet EREN Turkey model 50X50 with a 14 mm thickness is manufactured from a non-asbestos composite material with an average density of 2.05 g/cm³. The formulation includes 28% aramid and mineral fibers, 27% phenolic resin, 25% metallic powders bronze and copper, and 20% heat-resistant fillers. The unit surface weight is approximately 13.2 to 13.5 kg/m², making it suitable for heavy-duty industrial applications. The dry friction coefficient ranges between 0.41 and 0.46, ensuring high stability under elevated pressure and temperature conditions.

In terms of wear and thermal resistance, the EREN 14 mm sheet offers a wear rate of about 0.15 mm³/N·m and maintains steady performance in dry operation up to 370°C. Under lubricated conditions, the friction coefficient slightly decreases to 0.33–0.36 while maintaining operational stability. The lining provides short-term thermal resistance up to 420°C, and its adhesive composite structure prevents cracking or delamination during repeated thermal cycles. These characteristics make the 14 mm EREN sheet an ideal choice for industrial braking systems and hydraulic clutch assemblies.

| |

| lentmarket | 09122003350 |

| pedal-market |

| Iran |

| 021-55705400 |

Used van brake disc and clutch plate, Valeo brand

The used Valeo van brake disc is manufactured from low-alloy steel with hardened heat treatment, featuring an outer diameter of 305 millimeters and a standard thickness of 32 millimeters. Each disc weighs approximately 9 kilograms and can withstand operating temperatures up to 370 degrees Celsius. Mounting holes are spaced at a standard 120 millimeters, and cooling grooves are designed to ensure rapid heat dissipation and reduced braking noise. The contact surface with the brake pad is uniformly machined, ensuring balanced pressure distribution across the disc, minimizing vibration and preventing uneven wear.

The used Valeo van clutch plate is made of hardened steel with an anti-wear layer and has an outer diameter of 270 millimeters. The plate thickness is 9.5 millimeters, with a friction coefficient of 0.36 according to global standards. Reinforced damper springs reduce initial clutch shock and increase the overall durability of the assembly. The design of radial grooves and ventilation holes ensures fast heat transfer and prevents slippage under heavy load conditions. Connection to the flywheel is made using M12 bolts with a hole spacing of 115 millimeters.

| |

| pedal-market | 021-55705400 |

| pedal-market |

| Iran |

| 021-55705400 |

Used Megane brake disc and clutch plate, Valeo brand

The used Megane Valeo brake disc is manufactured from low-alloy steel with advanced heat treatment, featuring an outer diameter of 288 millimeters and a standard thickness of 28 millimeters. Each disc weighs approximately 7.6 kilograms and can withstand an operating temperature of up to 350 degrees Celsius. Mounting holes are spaced at a standard 114.3 millimeters, and ventilation grooves are designed for rapid heat dissipation and reduced brake noise. The contact surface with the pad is precisely machined to ensure even pressure distribution across the disc, minimizing vibration and uneven wear.

The used Megane Valeo clutch plate is made from hardened steel with an anti-wear coating and has an outer diameter of 242 millimeters. The plate thickness is 8.5 millimeters, with a friction coefficient of 0.35 according to international standards. Optimized damper springs reduce initial clutch shock and extend the overall assembly lifespan. Radial grooves and ventilation holes enhance heat transfer and minimize the risk of clutch slippage under heavy load conditions. Connection to the flywheel is made using M10 standard bolts with a hole spacing of 110 millimeters.

| |

| pedal-market | 021-55705400 |

| tehran-gearbox |

| Iran |

| 021-55406939 021-55426506 |

Steel factory industrial brake pads

Industrial brake pads for steel factories are designed to operate under very high temperatures and harsh working conditions, made from heat-resistant metallic and non-metallic compounds. The friction coefficient ranges from 0.4 to 0.48, providing stable performance at temperatures up to 600 degrees Celsius. Their thickness typically varies between 12 and 25 millimeters, with a density range of 2.6 to 3.1 grams per cubic centimeter. These pads offer high heat transfer capability and thermal shock resistance, essential for rolling lines, industrial furnaces, and heavy-duty transmission machinery.

Reinforced with metal fibers such as steel or brass wire, the structure increases mechanical strength and optimizes pad lifespan during repeated stop-and-go cycles. A multi-layer design with anti-wear coating reduces damage caused by impact pressures. These pads are usually manufactured according to international standards like ISO 11116 or DIN 15431. Resistance to environmental contaminants such as metal dust and industrial oils is another advantage. Steel factory industrial brake pads play a critical role in ensuring safety and efficiency in production processes.

| |

| tehran-gearbox | 021-55406939 021-55426506 |

| pedal-market |

| Iran |

| 021-55705400 |

Used Nissan brake disc and clutch plate, Valeo brand

The used Nissan Valeo brake disc is made of low-alloy steel with advanced heat treatment, featuring an outer diameter of 300 millimeters and a standard thickness of 30 millimeters. Each disc weighs approximately 8.5 kilograms and can withstand operating temperatures up to 360 degrees Celsius. Mounting holes are spaced at a standard 114.3 millimeters, and ventilation grooves are designed for rapid heat dissipation and reduced brake noise. The contact surface with the pad is precisely machined to ensure even pressure distribution across the disc, minimizing vibration and uneven wear.

The used Nissan Valeo clutch plate is manufactured from hardened steel with an anti-wear coating and has an outer diameter of 250 millimeters. The plate thickness is 9 millimeters, with a friction coefficient of 0.35 according to international standards. Optimized damper springs reduce initial clutch shock and extend the overall assembly lifespan. Radial grooves and ventilation holes improve heat transfer and minimize the risk of clutch slippage under heavy load conditions. Connection to the flywheel is achieved using M10 standard bolts with a hole spacing of 110 millimeters.

| |

| pedal-market | 021-55705400 |

| tehran-gearbox |

| Iran |

| 021-55406939 021-55426506 |

marine brake bronze

Bronze marine brake pads are specialized components used in maritime braking systems, manufactured from bronze alloy reinforced with graphite and wear-resistant additives. These pads are engineered to withstand high dynamic loads and continuous operation in humid and corrosive environments. Their coefficient of friction ranges from 0.3 to 0.36, offering stable performance at ambient temperatures from -10 to +500 degrees Celsius. Standard thickness varies between 10 and 25 millimeters, and surface hardness is approximately 80 to 100 Brinell. High thermal conductivity and oxidation resistance are key features of this product in marine environments.

These bronze pads have a density of about 7.5 to 8.2 grams per cubic centimeter, which helps absorb impact and evenly distribute force within the braking system. A porous structure with internal graphite dispersion enables self-lubrication and reduces wear during repeated contact. The design complies with ABS and DNV standards and is used in industrial boats, cargo ships, and naval vessels. Their machinability and custom sizing make them suitable for specialized engineering needs in the maritime industry.

| |

| tehran-gearbox | 021-55406939 021-55426506 |

| pedal-market |

| Iran |

| 021-55705400 |

Used Maxima brake disc and clutch plate, Valeo brand

The used Maxima Valeo brake disc is made of low-alloy steel with precise heat treatment, featuring an outer diameter of 300 millimeters and a standard thickness of 30 millimeters. Each disc weighs approximately 8.2 kilograms and can withstand a maximum operating temperature of 360 degrees Celsius. Mounting holes are spaced at a standard 114.3 millimeters, and ventilation grooves are designed for rapid heat dissipation and reduced brake noise. The contact surface with the pad is uniformly machined, ensuring even pressure distribution across the disc and minimizing vibration and uneven wear.

The used Maxima Valeo clutch plate is manufactured from hardened steel with an anti-wear coating, having an outer diameter of 250 millimeters. The plate thickness is 9 millimeters, with a friction coefficient of 0.36 according to international standards. Optimized damper springs reduce initial clutch shock and extend overall assembly lifespan. Radial grooves and ventilation holes enhance heat transfer and minimize the risk of clutch slippage under heavy loads. Connection to the flywheel is made using M10 standard bolts with a hole spacing of 110 millimeters.

| |

| pedal-market | 021-55705400 |

| lentmarket |

| Iran |

| 09122003350 |

16mm Eren 50X50 brake lining

The industrial non-asbestos brake lining sheet EREN Turkey model 50X50 with a 16 mm thickness is made from heat and wear-resistant composite materials. It has an average density of 2.08 g/cm³ and a unit surface weight of approximately 15.1 to 15.4 kg/m². The formulation consists of 30% aramid and mineral fibers, 25% reinforced phenolic resin, 25% metallic powders copper and bronze, and 20% heat-resistant mineral fillers. The dry friction coefficient ranges between 0.42 and 0.47, providing excellent stability under high mechanical and thermal loads.

In terms of wear resistance, the 16 mm EREN sheet demonstrates a wear rate of approximately 0.14 mm³/N·m, indicating exceptional durability under continuous frictional stress. It is designed to perform efficiently in both dry and semi-oil operating systems, with the lubricated friction coefficient remaining between 0.33 and 0.36. The continuous thermal resistance reaches up to 380°C, with short-term tolerance up to 430°C. Its dense structure and strong interlayer adhesion prevent cracking, delamination, and friction loss under heavy-duty industrial working conditions.

| |

| lentmarket | 09122003350 |

| Baygan-Sanat |

| Iran |

| 09196218230 |

Motogen brake motor

The Motogen brake motor from Tabriz is designed and manufactured in various power ranges from 0.18 kW to 30 kW. This three-phase motor operates at a voltage between 220 and 380 volts, with a rotational speed ranging from 1400 to 2900 RPM. The electromagnetic brake system responds in less than 0.2 seconds, providing fast and precise stopping of the motor shaft. The insulation class of these motors is selected based on international standards F or H, ensuring high thermal resistance and long service life. The motor housing is made of cast iron or aluminum, coated with corrosion- and moisture-resistant paint.

The protection rating of the Motogen brake motor from Tabriz is IP55, offering excellent resistance against dust and water ingress. These motors come with both foot-mounted and flange-mounted installation options for easy and secure setup in various industrial equipment. The standard operating temperature range is between -20 to +40 degrees Celsius, enabling reliable performance in harsh industrial environments. The bearing life is extended beyond 20,000 hours through the use of specialized industrial lubricants.

| |

| Baygan-Sanat | 09196218230 |

| lentmarket |

| Iran |

| 09122003350 |

10mm Eren brake lining

The industrial non-asbestos brake lining sheet EREN Turkey model 50X50 with a 10 mm thickness has a unit surface weight of approximately 9.7 to 10.1 kg per square meter. It is composed of aramid fibers, bronze powder, phenolic resin, and mineral friction modifiers, making it a safe and durable replacement for asbestos-based materials. Its chemical composition includes about 35% mineral fibers, 25% resin, 20% metallic powder, and 20% thermally stable fillers. The dry friction coefficient ranges between 0.40 and 0.46, ensuring smooth, uniform, and vibration-free braking performance in heavy-duty industrial systems.

The EREN non-asbestos brake lining demonstrates a wear resistance of about 0.18 mm³/N·m and maintains structural integrity under continuous frictional loads up to 380°C. The product undergoes strict quality control tests according to DIN 6951 and ISO 26865 standards to verify bonding strength, crack resistance, and friction stability. Designed for both dry and semi-oil applications, the 10 mm EREN lining offers a service life exceeding 1500 operational hours in high-load mechanical systems.

| |

| lentmarket | 09122003350 |

| lentmarket |

| Iran |

| 09122003350 |

2 ton demag hoist brake

The brake lining for the 2-ton Demag electric crane is made from asbestos-free friction material, combining phenolic resin and metallic fibers to ensure thermal resistance up to 300 °C and stable friction under heavy load. The initial thickness of the lining is typically between 10 and 12 mm, and the contact surface with the brake disc is designed to distribute pressure evenly, minimizing wear. The length and width of the lining are matched to the disc diameter and mounting spacing, with installation secured using vibration-resistant bolts tightened to a torque of 150 Nm.

The friction grade of the brake lining is calibrated between μ = 0.35 and 0.45 for optimal stopping performance in 2-ton hoists, ensuring precise load control without slippage. The lining design incorporates ventilation channels and longitudinal grooves to reduce operating temperature and extend service life beyond 10 years. The material composition and surface coating provide high resistance to moisture, dust, and corrosion, allowing repeated load cycles in demanding industrial environments.

| |

| lentmarket | 09122003350 |

| tgco |

| Iran |

| 021-55426506 |

brake woven roll

Ferdou roll brake pads are manufactured using a specialized combination of carbon fibers, phenolic resin, and mineral materials to achieve optimal mechanical and thermal resistance. These pads typically have a thickness ranging from 6 to 12 millimeters, with a friction coefficient between 0.42 and 0.52. The thermal resistance of Ferdou roll pads is guaranteed up to 520 degrees Celsius, and their wear rate is less than 0.05 millimeters per 1000 kilometers. The dense and cohesive structure of these pads reduces heat generation and prevents thermal cracking, ensuring durability and long-lasting performance.

The compressive strength of these pads measures up to 30 megapascals, with a surface hardness ranging from 70 to 85 Rockwell C. Specialized grooves on the pad surface enhance heat exchange and reduce operating temperature by up to 18 percent. Ferdou roll pads can withstand dynamic forces exceeding 1700 newtons and are widely used in high-pressure industrial braking systems. Their operational life is estimated to reach up to 90,000 braking cycles under standard conditions.

.jpg?width=160&height=160&cropratio=160:160&image=/admin/uploads/لنت-رول-فردو-brake-woven-roll-تی-جی-کو-51-u2053-images (37).jpg&url=/admin/uploads/لنت-رول-فردو-brake-woven-roll-تی-جی-کو-51-u2053-images (37).jpg)

.jpg?width=300&height=300&cropratio=300:300&image=/admin/uploads/لنت-رول-فردو-brake-woven-roll-تی-جی-کو-51-u2053-images (37).jpg&url=/admin/uploads/لنت-رول-فردو-brake-woven-roll-تی-جی-کو-51-u2053-images (37).jpg) | |

| tgco | 021-55426506 |

| tehran-gearbox |

| Iran |

| 021-55406939 021-55426506 |

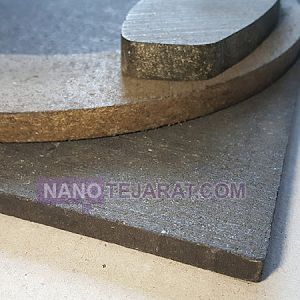

BRAKE PAD SHEET

Brake sheet linings are composed of carbon fibers, phenolic resin, and metallic particles to ensure high mechanical and thermal resistance. Their typical thickness ranges from 8 to 15 millimeters, and their coefficient of friction falls between 0.38 and 0.48. These linings can withstand operating temperatures up to 520 degrees Celsius, with a wear rate of less than 0.07 millimeters per 1,000 kilometers. The structural design of the brake sheet lining ensures uniform pressure distribution and reduces localized heat buildup, thereby enhancing braking performance and increasing service life.

The compressive strength of brake sheet linings is measured up to 25 megapascals, with surface hardness ranging from 65 to 80 Rockwell C. The surface grooves are engineered to improve ventilation and reduce operating temperature by up to 12 percent. These linings can endure dynamic forces exceeding 1600 newtons and are widely used in industrial and automotive braking systems. Their durability and stable performance are ensured even in humid environments and under high thermal stress.

| |

| tehran-gearbox | 021-55406939 021-55426506 |

| tehran-gearbox |

| Iran |

| 021-55406939 021-55426506 |

Erfurt press brake pads

The press pad brake lining of Erfurt is manufactured using a high-quality blend of organic and mineral materials, capable of withstanding operating temperatures up to 520°C. The thickness of these linings typically ranges from 8 to 15 millimeters, with a friction coefficient between 0.40 and 0.50. The lining structure consists of phenolic resin, carbon fibers, and metal particles, providing excellent mechanical and thermal resistance while preventing thermal cracks. The wear rate of this lining is less than 0.06 millimeters per 1000 kilometers, indicating its high durability and quality.

The compressive strength of the Erfurt press pad brake lining is reported up to 32 MPa, with a surface hardness ranging between 72 and 86 Rockwell C. The design of surface grooves enhances ventilation and reduces operating temperature by up to 17 percent. These linings can withstand dynamic forces exceeding 1800 Newtons and maintain stable performance in humid and dusty environments. Their service life in heavy industrial brake systems is estimated at up to 95,000 braking cycles.

| |

| tehran-gearbox | 021-55406939 021-55426506 |

| Baygan-Sanat |

| Iran |

| 09196218230 |

Kaijieli Brake Electric Motor

The Kaijieli brake motor is a three-phase induction motor equipped with a DC electromagnetic brake. It is available in a wide range of power outputs from 0.75 kW to 15 kW, and operates at 380 volts with a frequency of 50 Hz, providing stable performance in industrial environments. The motor runs at a rated speed of 1400 RPM, and its DC brake offers fast response and a manual release mechanism, designed for safe and immediate stopping.

This motor has a protection class of IP55, ensuring solid resistance against dust and water. Additionally, the insulation class of the Kaijieli Chinese brake motor is F, and it features an IC411 cooling system with an external fan. In terms of mounting, it supports both foot-mounted B3 and flange-mounted B5/B35 configurations, and is fully compatible with inverters Inverter Friendly. The housing is made of durable cast iron, resistant to impact and corrosion, while maintaining low noise and minimal vibration during operation. These features make it an ideal choice for continuous duty Duty Type S1 in demanding industrial applications.

| |

| Baygan-Sanat | 09196218230 |

| tehran-gearbox |

| Iran |

| 021-55406939 021-55426506 |

Brake presses

Press machine brake pads are manufactured using a composite structure of carbon fibers, phenolic resin, and mineral materials to ensure high thermal and mechanical resistance. The thickness of these pads typically ranges from 10 to 16 millimeters, with a friction coefficient between 0.40 and 0.52. They can withstand operating temperatures up to 520 degrees Celsius, and their wear rate is reported to be less than 0.06 millimeters per 1,000 kilometers. The dense pad structure enhances integrity and reduces thermal cracking under high pressure and temperature conditions.

The compressive strength of press machine brake pads reaches up to 32 megapascals, and surface hardness is measured between 72 and 85 Rockwell C. The pad surface design includes deep grooves that improve ventilation and reduce operating temperature by up to 18 percent. These pads can endure dynamic forces exceeding 2,500 newtons and are widely used in high-pressure industrial press braking systems. Their lifespan under standard conditions is estimated at up to 90,000 braking cycles.

| |

| tehran-gearbox | 021-55406939 021-55426506 |

| tehran-gearbox |

| Iran |

| 021-55406939 021-55426506 |

industrial brake pad sheet

Industrial sheet brake pads are manufactured using a compressed composite of organic and mineral materials to ensure high mechanical and thermal resistance. The thickness of these pads typically ranges from 8 to 15 millimeters, with a friction coefficient between 0.38 and 0.48. Their thermal resistance is reported up to 480 degrees Celsius, and the wear rate is less than 0.07 millimeters per 1,000 kilometers. The dense and integrated structure includes carbon fibers, phenolic resin, and metal particles, enhancing durability and reducing thermal cracking.

The compressive strength of this type of pad is measured up to 25 megapascals, with surface hardness varying between 65 and 80 Rockwell C. The pad’s surface grooves improve ventilation and reduce operating temperature by up to 12 percent. Industrial sheet brake pads can withstand dynamic forces exceeding 1,500 newtons and are widely used in medium-pressure industrial braking systems. Their service life is estimated up to 70,000 braking cycles under standard conditions.

| |

| tehran-gearbox | 021-55406939 021-55426506 |

| tehran-gearbox |

| Iran |

| 021-55406939 021-55426506 |

industrial bronze brake pad

Industrial bronze brake pads are composed of a bronze alloy, carbon fibers, and phenolic resin, designed for high thermal and mechanical resistance in industrial applications. Their coefficient of friction ranges between 0.35 and 0.45, with operating temperatures up to 550 degrees Celsius. Typical thickness varies from 8 to 15 millimeters, and the wear rate is reported below 0.07 millimeters per 1,000 kilometers. The material structure ensures optimal heat transfer and high resistance against corrosion and abrasion.

The compressive strength of industrial bronze pads reaches up to 30 megapascals, and surface hardness ranges from 70 to 85 Rockwell C. Surface design features parallel grooves and cooling channels that reduce operating temperature by up to 20 percent, enhancing pad lifespan. These pads are widely used in industrial brake systems, heavy-duty clutches, and mining machinery, capable of withstanding mechanical forces up to 2,500 newtons. Their durability in harsh conditions is estimated at up to 90,000 braking cycles.

| |

| tehran-gearbox | 021-55406939 021-55426506 |

| tehran-gearbox |

| Iran |

| 021-55406939 021-55426506 |

Brake pads sheep

The original brake pad backing plate is a key component in disc brake systems, serving as the base for the friction material. These plates are typically made from carbon steel with a thickness ranging from 5 to 7 millimeters and have a surface hardness between 180 and 220 Brinell. Manufacturing tolerance is maintained below 0.05 millimeters to ensure full contact with the brake piston and disc. Standard backing plates are coated with phosphate or zinc Zn to resist corrosion for up to 240 hours in salt spray tests.

The weight of each plate varies between 0.6 to 1.2 kilograms depending on the vehicle class and brake size. Drilled holes, grooves, and protrusions on the plate surface play a crucial role in reducing vibration and noise. Thermal deformation in cyclic heat tests is less than 0.02 millimeters. The yield strength measured in bending tests ranges from 280 to 350 megapascals, indicating high structural strength. The plate design must fully withstand hydraulic system pressures up to 120 bar.

| |

| tehran-gearbox | 021-55406939 021-55426506 |

| lentsazanco |

| Iran |

| 021-55406939 |

romani tractor brake

The Romanian tractor brake pad is manufactured using a combination of carbon fibers, phenolic resin, and mineral materials, providing thermal resistance up to 480°C. The thickness of these pads varies between 10 and 18 millimeters, with a friction coefficient ranging from 0.38 to 0.46. The wear rate is less than 0.07 millimeters per 1000 kilometers, and their compressive strength has been reported up to 25 megapascals. Due to their dense and cohesive structure, these pads perform reliably against thermal cracks and dynamic forces exceeding 1500 newtons.

The surface hardness of the Romanian tractor brake pad measures between 65 and 78 Rockwell C. The design of surface grooves enhances heat exchange and reduces operating temperature by up to 14 percent. These pads perform well in humid and dusty environments, with an estimated service life of up to 80,000 braking cycles under standard conditions. Their primary application is in braking systems of industrial and agricultural tractors.

| |

| lentsazanco | 021-55406939 |

| tehran-gearbox |

| Iran |

| 021-55406939 021-55426506 |

brake pad industrial

Industrial brake lining is a key component in heavy machinery braking and control systems, manufactured according to SAE J661 and ISO 26865 standards. These linings are typically made from a combination of organic fibers, phenolic resin, and metallic friction materials to provide a consistent friction coefficient between 0.35 and 0.45. The operating temperature range of industrial brake linings is 100 to 450°C, with safe performance maintained under momentary conditions up to 600°C.

The compressive strength of these linings is typically between 2000 and 3500 N/cm², which is critical for mining and steel industry applications. The standard wear rate is less than 0.30 mm per 1000 braking cycles, ensuring an operational lifespan exceeding 20,000 hours. The dimensions of industrial brake linings vary depending on the application, with thicknesses ranging from 8 to 25 mm and lengths from 50 to 300 mm.

| |

| tehran-gearbox | 021-55406939 021-55426506 |

| lentmarket |

| Iran |

| 09122003350 |

DEMAG 500kg conical brake

The brake lining used in a Demag 0.5 ton hoist is engineered according to the mechanical requirements of 500 kilogram lifting systems and typically features an initial thickness of 4 to 6 millimeters with a friction coefficient between 0.35 and 0.45 to generate an estimated braking torque of 45 to 70 newton meters. The effective friction diameter in this capacity range is usually selected between 80 and 110 millimeters to maintain torque stability under FEM 2m duty conditions. The lining material is formulated from high temperature resin combined with industrial fibers capable of resisting thermal loads up to about 220 degrees Celsius to minimize performance drop during repeated stops. This lining must dissipate roughly 200 to 350 watts of heat and maintain uniform contact pressure to prevent localized wear and avoid sudden increases in the brake air gap during intensive operating cycles.

| |

| lentmarket | 09122003350 |

| Baygan-Sanat |

| Iran |

| 09196218230 |

Siemens three-phase brake motor

The Siemens brake motor is one of the best choices for industrial applications that require fast and safe stopping.

Technical specifications of the Siemens brake motor SIEMENS motor:

Motor type: Three-phase induction motor

Power: From 0.37 kW up to 30 kW depending on project requirements

Operating voltage: 380 to 415 volts, 50/60 Hz

Motor speed: 750, 1000, 1500, 3000 RPM

Insulation class: F or H for higher thermal durability

Brake type: Electromechanical brake with fast response speed

Protection class: IP55 for resistance against dust and moisture

Body construction: Aluminum or cast iron depending on model and application

Suitable for: Production lines, transport equipment, cranes, presses, and other industrial machinery

For specialized consultation and pricing information about Siemens three-phase brake motors, please contact our experts.

| |

| Baygan-Sanat | 09196218230 |

| Baygan-Sanat |

| Iran |

| 09196218230 |

Chinese brake motor

The Chinese brake motor is one of the most widely used options across various industries. This type of electric motor, equipped with an internal braking system, offers the ability to quickly stop the output shaft—an essential feature for production lines, industrial machinery, cranes, conveyors, and CNC machines. If you are looking to purchase an affordable electric motor with acceptable quality and a reasonable service life, a Chinese brake motor can be a suitable choice.

Some users may be concerned about the quality of Chinese products, but many electric motor manufacturers in China have obtained international certifications such as CE and ISO in recent years. Therefore, by choosing a Chinese brake motor and selecting reputable brands such as Yongkun, Jie, Teco China, or Huali, you can benefit from reliable performance and solid engineering.

| |

| Baygan-Sanat | 09196218230 |

| Baygan-Sanat |

| Iran |

| 09196218230 |

MGM Brake Motor

The MGM Italy brake motor is a three-phase industrial motor equipped with an internal electromagnetic brake.

Technical Specifications of MGM Brake Motor

The technical specifications of the MGM Motors brake motor, made in Italy, are as follows:

Brake type: Electromagnetic spring brake AC or DC

Output power: From 0.18 kW up to 15 kW

Operating voltage: 220/380 volts three-phase

Frequency: 50 or 60 Hz

Protection class: IP55 or IP56 depending on the model

Thermal class: F or H

Frame size: From 63 to 160

Mounting options: Horizontal or vertical

Customization options: Available with encoder, forced fan, special flange

For the latest price inquiry and to purchase the MGM Italy brake motor, contact our experts now.

| |

| Baygan-Sanat | 09196218230 |

| shoping-14 |

| Iran |

| 02155433645 |

backhoe brake disc

The backhoe brake disc is made of alloy steel with 55–60 HRC surface hardness and tensile strength up to 800 MPa. Outer diameter ranges from 350 to 420 mm, with 15 mm thickness, supporting operational temperatures up to 300°C. Bolt holes are machined with ±0.1 mm precision, and dynamic balancing is accurate to 0.02 mm to reduce braking vibration.

The contact surface features cooling grooves that optimize airflow and oil distribution, lowering friction temperature by 20%. Brake disc weight ranges between 12 and 14 kg, with a service life of up to 2,000 hours under standard conditions. Anti-corrosion coating and wear-resistant heat treatment extend durability, while maintaining optimized friction coefficient at 0.35.

| |

| shoping-14 | 02155433645 |

| lentsazanco |

| Iran |

| 021-55406939 |

Demag Crane brake plate

Demag Crane Brake Plate that made by Lentsazan

| |

| lentsazanco | 021-55406939 |

| tehran-gearbox |

| Iran |

| 021-55406939 021-55426506 |

Forklift Brake Pad

forklift brake pad that made by tehran gearbox

| |

| tehran-gearbox | 021-55406939 021-55426506 |

| lentsazanco |

| Iran |

| 021-55406939 |

Sliding Brake Pads

sliding brake pads that made by Lentsazan

| |

| lentsazanco | 021-55406939 |

| tehran-gearbox |

| Iran |

| 021-55406939 021-55426506 |

Backhoe loader CUKUROVA friction brake

Backhoe loader CUKUROVA friction brake

| |

| tehran-gearbox | 021-55406939 021-55426506 |

| tehran-gearbox |

| Iran |

| 021-55406939 021-55426506 |

Airflex VC 60VC1600 Air clutch brake

Airflex VC 60VC1600 Air clutch brake

| |

| tehran-gearbox | 021-55406939 021-55426506 |

| lentsazanco |

| Iran |

| 021-55406939 |

Road roller Brake

road roller brake

| |

| lentsazanco | 021-55406939 |