- Pneumatic tools

- Hand tools

- Nuts,Bolts and Screws

- Cutting discs

- Audio equipments

- Cable, Wire and Accessories

- Dental equipment

- Laser

- Concrete Pump

- Cutting and shaping tools

- Drilling Insert(29)

- INSERT(11)

- Ceramic turning inserts(5)

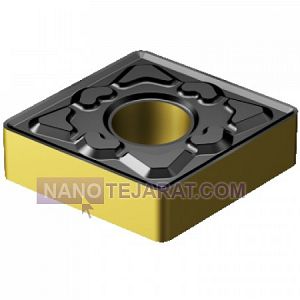

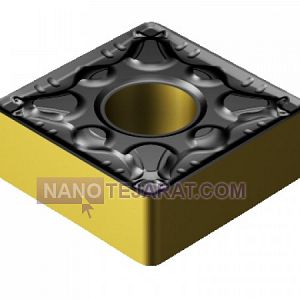

- Lathe insert cnmg120404(4)

- insert(3)

- Tread Turning Inserts(3)

- THREAD TURNING INSERTS(3)

- INSERT(3)

- CBN Insert(2)

- INSERT(2)

- PCD INSERT(2)

- THREAD TURNING INSERTS(2)

- Sandvik cutting insert(2)

- carbide insert tools(2)

- TURNING INSERT(2)

- CHANGEABLE 2INSERTS ROUGH BORING HEAD VRB(1)

- PKD INSERT(1)

- CHANGEABLE 2INSERTS ROUGH BORING HEAD VRB(1)

- VBMT INSERT(1)

- CRT ROUND INSERT END MILLS(1)

- brazed insert(1)

- Walter CNMG190612-RM5 Diamond Turning Insert(1)

- THREAD TURNING INSERTS(1)

- Diamond turning insert TNMG220408-MS3(1)

- THREAD TURNING INSERTS(1)

- ROUND INSERT MILLING CUTTER(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- INSERT TPMR 322 160308 IC907 ISCAR(1)

- Baker Insert(1)

- ceramics insert(1)

- almase insert gam zani(1)

- RNG turning insert with TIN coating(1)

- INSERT SANDVIK .SECO(1)

- TNMG22 lathe insert(1)

- TNMG16 lathe insert for steel(1)

- CHANGEABLE 2INSERTS ROUGH BORING HEAD VRB(1)

- INSERT DNMG(1)

- CHANGEABLE 2INSERTS ROUGH BORING HEAD VRB(1)

- CHANGEABLE 2INSERTS ROUGH BORING HEAD VRB(1)

- WALTER INSERT(1)

- INSERT FOR TURNING AND MILLING(1)

- CHANGEABLE 2INSERTS ROUGH BORING HEAD VRB(1)

- CHANGEABLE 2INSERTS ROUGH BORING HEAD VRB(1)

- PRAMET INSERT(1)

- CRT ROUND INSERT END MILLS(1)

- THREAD TURNING INSERTS(1)

- Diamond turning insert TNMG160412-MP5(1)

- THREAD TURNING INSERTS(1)

- INSERT TNMG220404-MS3(1)

- THREAD TURNING INSERTS(1)

- ROUND INSERT MILLING CUTTER(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- PCD insert(1)

- INSERT TPKN -PDR 160308 IC907 ISCAR(1)

- INSERT(1)

- insert(1)

- -insert(1)

- INSERT(1)

- korloy grooving insert(1)

- TNMG22 lathe insert for cast iron lathe(1)

- RNMN Turning Insert SANDVIK(1)

- INSERT(1)

- CHANGEABLE 2INSERTS ROUGH BORING HEAD VRB(1)

- THREAD TURNING INSERTS(1)

- CHANGEABLE 2INSERTS ROUGH BORING HEAD VRB(1)

- ZCC INSERT(1)

- CHANGEABLE 2INSERTS ROUGH BORING HEAD VRB(1)

- CHANGEABLE 2INSERTS ROUGH BORING HEAD VRB(1)

- insert (1)

- CHANGEABLE 2INSERTS ROUGH BORING HEAD VRB(1)

- insert(1)

- CHANGEABLE 2INSERTS ROUGH BORING HEAD VRB(1)

- insert(1)

- CRT ROUND INSERT END MILLS(1)

- THREAD TURNING INSERTS(1)

- INSERT DNMG 150608-MS3BOW(1)

- THREAD TURNING INSERTS(1)

- ROUND INSERT MILLING CUTTER(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- INSERT HOLDER FACE GROOVING(1)

- INSERT TPKN 422 120308 IC907 ISCAR(1)

- insert(1)

- INSERTS(1)

- Sandvik turning insert model VBMT 16(1)

- Sandvik turning insert model RCGX09(1)

- TNMG22 lathe insert(1)

- TNMG22 lathe insert for steel(1)

- TURNING INSERT(1)

- ARNO INSERT(1)

- THREAD TURNING INSERTS(1)

- CHANGEABLE 2INSERTS ROUGH BORING HEAD VRB(1)

- INSERT TPKN(1)

- CHANGEABLE 2INSERTS ROUGH BORING HEAD VRB(1)

- INSERT KORLOY(1)

- CHANGEABLE 2INSERTS ROUGH BORING HEAD VRB(1)

- INSERT TPKN22(1)

- CHANGEABLE 2INSERTS ROUGH BORING HEAD VRB(1)

- LAMINA INSERT(1)

- CHANGEABLE 2INSERTS ROUGH BORING HEAD VRB(1)

- insert(1)

- CRT ROUND INSERT END MILLS(1)

- THREAD TURNING INSERTS(1)

- Diamond turning insert TNMG220412-NR4(1)

- THREAD TURNING INSERTS(1)

- ROUND INSERT MILLING CUTTER(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- TURNING INSERTS(1)

- Baker Insert(1)

- Insert(1)

- INSERT VBMT(1)

- Sandvik RNMG Model Turning Insert(1)

- carbide insert tools(1)

- insert(1)

- TCG22 lathe insert for aluminum(1)

- CHANGEABLE 2INSERTS ROUGH BORING HEAD VRB(1)

- ALUMINIUM INSERT(1)

- CHANGEABLE 2INSERTS ROUGH BORING HEAD VRB(1)

- INSERT APKT(1)

- CHANGEABLE 2INSERTS ROUGH BORING HEAD VRB(1)

- SANDVIK INSERT(1)

- Measuring equipment

- insert cut(2)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert CUT(1)

- insert(1)

- insert cut(1)

- insert cut(1)

- INSERT (1)

- INSERT DCMT (1)

- BINSERT CCMT(1)

- INSERT (1)

- INSERT (1)

- INSERT SPKN (1)

- INSERT RCGT(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert cut(1)

- INSERT KNUX (1)

- INSERT VBMT (1)

- INSERT (1)

- INSERT (1)

- INSERT(1)

- INSERT(1)

- INSERT (1)

- INSERT (1)

- Turning Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert cut(1)

- insert(1)

- INSERT (1)

- INSERT (1)

- INSERT(1)

- INSERT(1)

- INSERT(1)

- INSERT TPUN(1)

- INSERT(1)

- INSERT (1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert(1)

- insert cut(1)

- insert cut(1)

- INSERT(1)

- INSERT(1)

- INSERT (1)

- INSERT (1)

- INSERT(1)

- INSERT TPKN(1)

- INSERT CCGT (1)

- INSERT SPKN 12(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

- Threaded Inserts(1)

Insert

Search Results For Insert| behradsanatpars |

| Iran |

| 021-66723241 |

INSERT

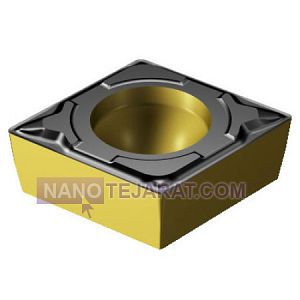

A turning insert is a replaceable cutting component designed for high-precision material removal, typically made from materials such as tungsten carbide or CBN. It features a surface hardness exceeding 2500HV, offering excellent wear resistance. The rake angle ranges from 5 to 25 degrees, while the clearance angle is typically between 5 and 7 degrees. The insert geometry includes a cutting edge length of 12.7 mm, a thickness of 4.76 mm, and a nose radius between 0.2 and 1.2 mm. Coatings such as TiAlN or Al₂O₃ are applied to reduce friction and extend tool life up to 90 minutes of continuous machining. Each insert is precisely engineered according to ISO 1832 standards to ensure consistent performance under demanding machining conditions.

Turning inserts perform efficiently at cutting speeds up to 400 meters per minute and feed rates ranging from 0.05 to 0.5 mm. They withstand thermal loads up to 800°C without compromising performance. Positive or negative rake designs optimize chip flow and machining stability. These inserts are compatible with standard holders such as CNMG, DNMG, or SNMG, used for roughing or finishing operations. Each insert is identified by a specific code that defines its shape, thickness, tolerance, and angle according to international standards. Pro

| |

| behradsanatpars | 021-66723241 |

| behradsanatpars |

| Iran |

| 021-66723241 |

INSERT

A turning insert is a replaceable cutting component designed for high-precision material removal, typically made from materials such as tungsten carbide or CBN. It features a surface hardness exceeding 2500HV, offering excellent wear resistance. The rake angle ranges from 5 to 25 degrees, while the clearance angle is typically between 5 and 7 degrees. The insert geometry includes a cutting edge length of 12.7 mm, a thickness of 4.76 mm, and a nose radius between 0.2 and 1.2 mm. Coatings such as TiAlN or Al₂O₃ are applied to reduce friction and extend tool life up to 90 minutes of continuous machining. Each insert is precisely engineered according to ISO 1832 standards to ensure consistent performance under demanding machining conditions.

Turning inserts perform efficiently at cutting speeds up to 400 meters per minute and feed rates ranging from 0.05 to 0.5 mm. They withstand thermal loads up to 800°C without compromising performance. Positive or negative rake designs optimize chip flow and machining stability. These inserts are compatible with standard holders such as CNMG, DNMG, or SNMG, used for roughing or finishing operations. Each insert is identified by a specific code that defines its shape, thickness, tolerance, and angle according to international standards. Pro

| |

| behradsanatpars | 021-66723241 |

| behradsanatpars |

| Iran |

| 021-66723241 |

INSERT

A turning insert is a replaceable cutting component mounted on machining tools such as boring bars or turning holders. Inserts are typically made from tungsten carbide, ceramics, or CBN and have a high hardness rating up to 92 HRA. Their rake angle ranges from 5 to 25 degrees, depending on the operation type and workpiece material. Standard insert dimensions follow ANSI or ISO codes, such as a diameter of 12.7 mm and a thickness of 4.76 mm. The contact surface is often coated with materials like TiN or Al₂O₃, enhancing wear resistance by up to three times. The insert geometry includes rounded or angled corners with a nose radius between 0.2 and 1.2 mm, directly affecting the surface finish quality.

Turning inserts can operate at cutting speeds up to 400 meters per minute and are suitable for precision machining with feed rates between 0.05 and 0.5 mm. In industrial applications, they withstand temperatures up to 800°C without performance degradation. A clearance angle of 5 to 7 degrees reduces friction and extends tool life. Insert coding includes detailed specifications such as shape, angle, thickness, and dimensional tolerance according to ISO 1832 standards. Inserts are compatible with various holders like CNMG or TNMG, used for roughing or finishing operations. With p

.jpg?width=160&height=160&cropratio=160:160&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (11).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (11).jpg)

.jpg?width=300&height=300&cropratio=300:300&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (11).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (11).jpg) | |

| behradsanatpars | 021-66723241 |

| bakutools |

| Iran |

| 09123691065 |

Walter CNMG190612-RM5 Diamond Turning Insert

The Walter CNMG190612-RM5 diamond turning insert is a precision-engineered square insert designed for machining hardened steels, cast iron, and heat-resistant alloys. It features dimensions of 19.05 × 6.35 mm with a 1.2 mm nose radius and conforms to the CNMG ISO standard. Its negative rake angle and balanced thickness enable stable cutting under heavy load conditions. The carbide grade used in combination with AlTiN and TiCN multilayer coatings extends tool life by up to 30% compared to similar inserts. The RM5 geometry is optimized for medium to semi-rough turning and delivers effective chip control at high speeds. This insert performs reliably in both continuous and interrupted cutting operations.

The insert’s engineering is based on precision pressing technology and nano-layered coatings, which significantly enhance its mechanical and thermal resistance. The applied cutting geometry evenly distributes stress across the cutting edge, preventing premature cracking. Its optimized corner design improves final surface finish and reduces the need for secondary polishing. Each insert weighs approximately 14.8 grams, striking a balance between mass and rigidity. Compatibility with standard ISO toolholders enables fast tool changes and boosts productivity in manufacturing enviro

| |

| bakutools | 09123691065 |

| behradsanatpars |

| Iran |

| 021-66723241 |

INSERT

A turning insert is a replaceable cutting tool made from materials such as tungsten carbide, CBN, or ceramics, with a surface hardness exceeding 2500HV. Inserts typically have a rake angle between 5 and 25 degrees and a clearance angle from 5 to 7 degrees, optimizing chip evacuation and reducing friction. Standard insert dimensions include a thickness of 4.76 mm, an edge length of 12.7 mm, and a nose radius ranging from 0.2 to 1.2 mm. Coatings like TiCN, AlTiN, or CVD are applied to enhance wear and heat resistance up to 800°C. These inserts are precisely engineered according to ISO 1832 standards and are compatible with toolholders using CNMG or SNMG systems.

Turning inserts can operate at cutting speeds up to 400 meters per minute and feed rates between 0.05 and 0.5 mm per revolution. These parameters improve production efficiency and reduce machining time. The insert geometry includes single- or double-sided cutting edges and accurate angles to control cutting forces and minimize vibration. Each insert is encoded with detailed information such as shape, thickness, rake angle, clearance angle, and dimensional tolerances. This coding enables fast identification and replacement in production lines. Proper use of cutting parameters and lubrication can extend the insert’s eff

| |

| behradsanatpars | 021-66723241 |

| bakutools |

| Iran |

| 09123691065 |

Diamond turning insert TNMG220408-MS3

The technical specifications of the TNMG220408-MS3 diamond cutting insert feature high precision and notable wear resistance, designed for machining hard and semi-hard materials. This insert is made from synthetic diamond with a hardness exceeding 9500 Vickers and can withstand temperatures up to 800 degrees Celsius. Its dimensions include a cutting length of 22 millimeters, a thickness of 4 millimeters, and an 80-degree nose angle, which enhances cutting accuracy and reduces cutting forces. The TNMG220408-MS3’s geometric design minimizes vibrations and increases tool life by up to 30 percent. It supports high cutting speeds up to 150 meters per minute, making it highly suitable for aerospace and automotive industries.

The structure of this diamond cutting insert incorporates multi-layer coatings such as TiAlN, which improve resistance to oxidation and wear. The low friction coefficient of these coatings reduces chip adhesion and enhances surface finish quality. With a positive rake angle and optimized chip breakers, the TNMG220408-MS3 facilitates chip flow and decreases tool load. Weighing approximately 8 grams, it balances strength and lightness effectively. These features make the TNMG220408-MS3 an ideal choice for precision machining and mass production across various in

| |

| bakutools | 09123691065 |

| behradsanatpars |

| Iran |

| 021-66723241 |

INSERT

A turning insert is made from materials such as tungsten carbide, ceramics, or CBN, with a surface hardness exceeding 2500HV. The standard thickness of inserts is typically 4.76 mm, and the cutting edge length is 12.7 mm. The rake angle ranges between 5 and 25 degrees, and the clearance angle is set between 5 and 7 degrees to balance cutting efficiency and wear reduction. The insert’s nose radius usually varies from 0.2 to 1.2 mm, improving the final surface quality. Coatings like TiAlN or Al₂O₃ are applied to enhance wear and heat resistance up to 800°C. These tools are designed and coded according to ISO 1832 standards.

Turning inserts can operate at cutting speeds up to 400 meters per minute and feed rates between 0.05 and 0.5 mm per revolution. These parameters increase productivity and reduce machining time. The insert geometry includes single- or double-sided cutting edges to control cutting forces and reduce vibration. Each insert has a specific code containing geometric shape, thickness, rake angle, and dimensional tolerances. These specifications enable quick identification and replacement in production lines. Proper use of cutting parameters and lubrication can extend tool life up to 90 minutes of continuous operation.

.png?width=160&height=160&cropratio=160:160&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-272c8f-download (1).png&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-272c8f-download (1).png)

.png?width=300&height=300&cropratio=300:300&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-272c8f-download (1).png&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-272c8f-download (1).png) | |

| behradsanatpars | 021-66723241 |

| mtco |

| Iran |

| 09123691065 |

insert

Sandvik turning inserts are made from tungsten carbide with an advanced TiAlN coating that provides thermal resistance up to 1000 degrees Celsius. Typical dimensions include a thickness of 4.76 mm, cutting edge length between 8 to 12.7 mm, and nose radius ranging from 0.4 to 1.2 mm, which play a crucial role in precise chip removal and extended tool life. The positive rake angle varies between 7 to 20 degrees, and the clearance angle is 6 to 7 degrees, helping to reduce cutting forces and prevent vibration. Sandvik inserts are available in geometric types such as TNMG, CNMG, and TCGT, each optimized for different materials like steel, stainless steel, and aluminum.

Under operating conditions, Sandvik turning inserts can withstand cutting speeds from 250 to 700 meters per minute and feed rates from 0.1 to 0.4 millimeters per revolution, depending on the workpiece material. The nano-layer coating technology and optimized insert geometry increase machining accuracy and reduce tool failure. Precise manufacturing standards compliant with ISO 9001 ensure quality and quick insert replacement in tool holders. Proper use of coolant can extend tool life up to 150 minutes under heavy machining conditions.

| |

| mtco | 09123691065 |

| behradsanatpars |

| Iran |

| 021-66723241 |

CBN turning inserts

CBN turning inserts, made from cubic boron nitride, are used for machining very hard materials such as heat-treated alloy steels with hardness above 45 HRC. These inserts typically have a hardness of 4000 to 4500 Vickers and thermal resistance up to 1200°C. Their structure usually consists of a thin CBN layer about 0.5 to 1 millimeter thick over a carbide substrate. The cutting angle ranges between 5 to 7 degrees, and the nose radius is typically between 0.2 to 0.8 millimeters. Precise design enables maintaining high material removal rates at high speeds while minimizing tool wear.

CBN inserts perform optimally at cutting speeds above 200 meters per minute and are suitable for dry machining. They are used for precision tolerances of 0.01 millimeters in parts such as crankshafts, shafts, and bearings. Protective coatings like TiAlN or TiSiN improve chemical and wear resistance in some models. The tool life of CBN inserts can be up to five times longer than carbide inserts depending on process conditions. Common geometries include CNGA, DNGA, and SNGA, optimized for medium to heavy-duty applications. These tools maintain stable operation temperatures without coolant up to 1000°C.

.jpg?width=160&height=160&cropratio=160:160&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (21).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (21).jpg)

.jpg?width=300&height=300&cropratio=300:300&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (21).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (21).jpg) | |

| behradsanatpars | 021-66723241 |

| bakutools |

| Iran |

| 09123691065 |

Diamond turning insert TNMG160412-MP5

The TNMG160412-MP5 diamond cutting tool is a popular and widely used instrument in the machining industry, designed for precise and efficient material removal from various hardened steels, heat-resistant alloys, and non-ferrous metals. Made from industrial diamond with high hardness and a uniform crystalline structure, this tool features a specially designed tip and optimized cutting angle that help reduce cutting forces and improve surface finish quality. Its high resistance to wear and heat makes it highly suitable for high-speed machining operations and demanding working conditions.

Structurally, the Walter TNMG160412-MP5 is manufactured as replaceable inserts with advanced nano and ceramic coatings that play a significant role in reducing friction and enhancing tool durability. The edge thickness, precise tip geometry, and easy mounting capability on CNC machines make this diamond cutting tool an ideal choice for industries such as automotive, aerospace, and mold making. Adherence to strict technical and structural standards in the design and production of this tool ensures increased productivity, reduced manufacturing costs, and improved final part quality.

| |

| bakutools | 09123691065 |

| novinteknik |

| Iran |

| 09122470269 |

Turning inserts

Turning inserts are a key component in metal machining processes, playing a crucial role in cutting accuracy and quality. Standard dimensions typically include cutting edge lengths between 6 to 25 millimeters and thicknesses from 2 to 5 millimeters. The insert material is commonly tungsten carbide, ceramic, or CBN, each designed for specific applications. Common coatings include TiN, TiAlN, and Al2O3, which increase wear and heat resistance up to over 1000 degrees Celsius. The cutting edge geometry is selected based on the machining type, such as precision or rough turning, and can have positive or negative rake angles.

The mechanical strength of the turning insert depends on its base material and coating, with hardness usually ranging between 1500 to 2200 Vickers. High-quality inserts can withstand shear forces up to 3000 Newtons and operating temperatures above 900 degrees Celsius. Tool life typically ranges from 30 to 120 minutes at cutting speeds of 100 to 300 meters per minute. Manufacturing precision within micron levels and dimensional tolerances below 0.01 millimeters enhances workpiece surface quality and reduces secondary costs.

.jpg?width=160&height=160&cropratio=160:160&image=/admin/uploads/اینسرت-تراشکاری--نوین-تکنیک-168-u2420-انواع-اینسرت-تراشکاری (1).jpg&url=/admin/uploads/اینسرت-تراشکاری--نوین-تکنیک-168-u2420-انواع-اینسرت-تراشکاری (1).jpg)

.jpg?width=300&height=300&cropratio=300:300&image=/admin/uploads/اینسرت-تراشکاری--نوین-تکنیک-168-u2420-انواع-اینسرت-تراشکاری (1).jpg&url=/admin/uploads/اینسرت-تراشکاری--نوین-تکنیک-168-u2420-انواع-اینسرت-تراشکاری (1).jpg) | |

| novinteknik | 09122470269 |

| mtco |

| Iran |

| 09123691065 |

TURNING INSERT

Sure! Heres the English translation of the provided technical text:

---

ZCC turning inserts are typically manufactured from tungsten carbide alloy with an approximate density of 14.5 g/cm³ and coatings such as PVD TiAlN or CVD TiCN. The insert thickness ranges between 3.18 to 6.35 mm and the nose radius varies from 0.4 to 1.2 mm. The positive rake angle is designed between 7 to 15 degrees to ensure smooth cutting and reduce vibration. ZCC inserts comply with ISO and DIN standards, allowing compatibility with various tool holders. The precise material composition enhances hardness up to approximately 92 HRA, contributing to stable performance at high cutting speeds.

The optimal cutting speed range for ZCC turning inserts on alloy steels is between 180 and 450 meters per minute. The typical feed rate is set between 0.1 and 0.35 mm/rev. Common geometries include CNMG, SNMG, and WNMG, designed with optimized angles for improved chip evacuation and reduced heat generation. Under proper cooling conditions, tool life can exceed 120 minutes. ZCC’s multilayer coating structure guarantees high resistance to wear and corrosion.

| |

| mtco | 09123691065 |

| jafar-esmaili-t |

| Iran |

TNMG22 lathe insert

The TNMG22 turning insert designed for cast iron is made from tungsten carbide with a surface hardness above 2600HV. The cutting edge length is 12.7 mm and the thickness is 4.76 mm. A nose radius of 0.8 mm helps improve surface quality and chip control. The rake angle is 15 degrees and the clearance angle is 7 degrees, optimized for efficient cast iron machining. The TiAlN coating provides thermal resistance up to 900°C and increases tool life against wear. The insert is coded according to ISO 1832 standards and compatible with CNMG and DNMG tool holders.

This insert can operate at cutting speeds up to 320 meters per minute and feed rates between 0.1 and 0.35 mm per revolution, ideal for cast iron machining. Its double-sided geometry with wear-resistant edges reduces vibration and enhances machining stability. The coding includes geometric data, coating type, and dimensional tolerances, enabling quick identification and easy replacement. Proper use of cutting parameters and optimized lubrication can extend the insert’s effective life up to 85 minutes and improve the surface finish quality of the workpiece.

| |

| jafar-esmaili-t | |

| jafar-esmaili-t |

| Iran |

TNMG22 lathe insert for cast iron lathe

The TNMG22 turning insert designed for stainless steel machining is made from tungsten carbide with a surface hardness exceeding 2700HV. The cutting edge length is 12.7 mm, thickness 4.76 mm, and nose radius 0.8 mm, improving cutting quality and chip control in hard metals. The rake angle is 15 degrees and clearance angle 7 degrees, engineered to reduce cutting forces and extend tool life. The TiAlN coating increases wear and heat resistance up to 950°C. This TNMG22 insert is manufactured according to ISO 1832 standards and fully compatible with CNMG and DNMG tool holders.

The TNMG22 insert can withstand cutting speeds between 250 and 350 meters per minute and feed rates from 0.1 to 0.3 mm per revolution, ideal for stainless steel machining. Its double-sided geometry with wear-resistant edges reduces vibration and enhances machining stability. Precise coding includes geometric features, coating type, and dimensional tolerances, facilitating quick and accurate tool replacement. Optimized cutting parameters and proper lubrication increase the insert’s service life and improve the workpiece surface quality.

| |

| jafar-esmaili-t | |

| hart-metal |

| Iran |

| 09123691065 |

TNMG22 lathe insert

The TNMG22 turning insert is made of tungsten carbide with a surface hardness exceeding 2500HV, suitable for machining steel and alloy materials. The insert has a cutting edge length of 12.7 mm and a thickness of 4.76 mm, optimized with a nose radius of 0.8 mm. Its rake angle is set at 15 degrees and clearance angle at 7 degrees to balance tool life and final surface quality. A TiAlN coating enhances wear and heat resistance up to 900°C. The insert is coded according to ISO 1832 standards and fully compatible with CNMG and DNMG tool holders.

The TNMG22 insert can withstand cutting speeds up to 350 meters per minute and feed rates between 0.1 and 0.4 mm per revolution, suitable for roughing and finishing operations. Its double-sided geometry with wear-resistant edges reduces vibration and improves machining stability. The insert’s coding includes geometric features, coating type, and dimensional tolerances, aiding quick selection and replacement. Proper cutting parameters and optimized lubrication extend the insert’s effective life up to 80 minutes and improve the workpiece surface quality.

.jpg?width=160&height=160&cropratio=160:160&image=/admin/uploads/اینسرت-تراشکاری-TNMG22-TNMG22-lathe-insert-ضایعات-اینسرت-تراشکاری-نقي-زاده-168-u2028-download (2).jpg&url=/admin/uploads/اینسرت-تراشکاری-TNMG22-TNMG22-lathe-insert-ضایعات-اینسرت-تراشکاری-نقي-زاده-168-u2028-download (2).jpg)

.jpg?width=300&height=300&cropratio=300:300&image=/admin/uploads/اینسرت-تراشکاری-TNMG22-TNMG22-lathe-insert-ضایعات-اینسرت-تراشکاری-نقي-زاده-168-u2028-download (2).jpg&url=/admin/uploads/اینسرت-تراشکاری-TNMG22-TNMG22-lathe-insert-ضایعات-اینسرت-تراشکاری-نقي-زاده-168-u2028-download (2).jpg) | |

| hart-metal | 09123691065 |

| jafar-esmaili-t |

| Iran |

TNMG22 lathe insert for steel

The TNMG22 turning insert for steel is made of tungsten carbide with a surface hardness exceeding 2600HV, ideal for machining alloy and hardened steels. The insert has a cutting edge length of 12.7 mm, thickness of 4.76 mm, and a nose radius of 0.8 mm, which improves chip control and machining accuracy. The rake angle is 15 degrees and the clearance angle is 7 degrees, designed to increase tool life and enhance final surface quality. The TiAlN coating offers heat resistance up to 900°C, increasing wear resistance and extending the insert’s service life.

The TNMG22 steel insert can operate at cutting speeds between 300 and 400 meters per minute and feed rates from 0.1 to 0.35 mm per revolution, improving productivity and reducing machining time. Its double-sided design reduces vibration and enhances machining stability. Precise coding includes geometric features, coating type, and dimensional tolerances, enabling quick identification and replacement. Optimal cutting parameters and lubrication can extend tool life up to 90 minutes and ensure high surface finish quality on the workpiece.

| |

| jafar-esmaili-t | |

| behradsanatpars |

| Iran |

| 021-66723241 |

RNG turning insert with TIN coating

The RNG turning inserts with TiN coating are among the most advanced cutting tools, manufactured with a dimensional accuracy of ±0.01 millimeters. These inserts are made from tungsten carbide with a hardness of 1800-2000 HV and have a TiN coating thickness of approximately 2 microns. The TiN coating reduces the friction coefficient to 0.3 and provides thermal resistance up to 800 degrees Celsius, increasing tool life by up to 40%. These inserts are available in various geometric shapes such as RNG-32 and RNG-43, featuring a cutting edge length of 3.2 millimeters and a 55-degree angle.

The optimal performance of RNG turning inserts with TiN coating is ensured at cutting speeds of 150-300 meters per minute and cutting depths of 0.5 to 2 millimeters. High precision in vibration control and noise reduction improves the surface quality of the workpiece. High wear resistance and suitability for machining various hardened and alloy steels are key features of these inserts. Each package contains 10 pieces weighing approximately 50 grams, widely used in automotive and aerospace industries.

.jpg?width=160&height=160&cropratio=160:160&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-download (9).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-download (9).jpg)

.jpg?width=300&height=300&cropratio=300:300&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-download (9).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-download (9).jpg) | |

| behradsanatpars | 021-66723241 |

| bakutools |

| Iran |

| 09123691065 |

Diamond turning insert TNMG220412-NR4

The TNMG220412-NR4 turning diamond features an advanced TiN/TiCN coating that provides high resistance to wear and heat. This insert is designed with a cutting length of 22 millimeters and a thickness of 4.12 millimeters to deliver precise machining of various hard steels. Its 80-degree nose angle increases tool strength and reduces mechanical stress. The specially engineered chip breakers optimize chip flow and minimize vibrations during turning. The tool weighs approximately 7.5 grams and can withstand cutting speeds up to 140 meters per minute. These features contribute to longer tool life in automotive and aerospace industries.

Additionally, the structural design of the TNMG220412-NR4 turning diamond helps reduce heat in the cutting zone, maintaining high surface quality of machined parts. Its high impact resistance and reduced wear lower tool replacement costs. With precise engineering, this turning diamond performs optimally in machining hard and semi-hard metals. Overall, the TNMG220412-NR4 is an ideal choice for industrial applications demanding durability and high accuracy.

| |

| bakutools | 09123691065 |

| TSK-tools |

| Iran |

| 02166747975 |

Diamond Turning Insert WNMG 060404 EM YBG202

The WNMG 060404 EM YBG202 turning insert features standard dimensions of 6.35 × 6.35 millimeters with a nose radius of 0.4 millimeters, designed for precise turning and finishing operations. This insert is made of YBG202 grade carbide, offering a combination of high hardness and excellent wear resistance. Its multi-layer TiAlN coating ensures thermal resistance up to 950 degrees Celsius, enhancing tool performance under demanding conditions. The WNMG geometry with a medium rake angle and optimized design provides controlled chip flow and reduces vibration during cutting.

The YBG202 grade of the WNMG 060404 EM insert is optimized for machining alloy steels and medium hardness carbon steels. The insert thickness is 4.76 millimeters, balancing strength and flexibility. Due to its high wear resistance and thermal stability, this tool offers a long service life in heavy industrial applications. Additionally, the 7-degree rake angle reduces cutting forces and improves surface finish quality. The WNMG 060404 EM YBG202 insert is compatible with standard ISO tool holders.

| |

| TSK-tools | 02166747975 |

| behradsanatpars |

| Iran |

| 021-66723241 |

Ceramic turning inserts

Ceramic turning inserts are made from alumina Al2O3 compounds with additives such as zirconia, exhibiting hardness between 1800 and 2200 HV. These inserts maintain stable performance at operating temperatures above 1000 degrees Celsius and show very high wear resistance. Standard insert dimensions typically range from 6 to 20 millimeters in length and width. The main cutting angle ranges from 0 to 15 degrees, with a clearance angle of approximately 7 degrees, designed to ensure smooth and high-quality cutting. Insert thickness usually varies between 3 to 6 millimeters, and their weight ranges from 3 to 10 grams.

Due to their high thermal resistance and hardness, these inserts are primarily used in machining hard metals and cast iron. The insert mounting system, with precision under 0.01 millimeters, guarantees high stability during the turning process. Special coatings like TiCN and Al2O3 enhance tool life and reduce friction. These features improve efficiency and lower tool replacement costs, playing a crucial role in manufacturing precise and durable components.

| |

| behradsanatpars | 021-66723241 |

| jafar-esmaili-t |

| Iran |

TNMG16 lathe insert for steel

The TNMG16 turning insert for stainless steel is made from tungsten carbide with a surface hardness exceeding 2700HV. The cutting edge length is 8 mm, thickness 4.76 mm, and nose radius 0.4 mm, providing better chip control and high cutting precision. The rake angle is 15 degrees and clearance angle 7 degrees, which reduce cutting forces and extend tool life. The TiAlN coating improves wear and heat resistance up to 950 degrees Celsius. The TNMG16 insert is manufactured according to ISO 1832 standards and is compatible with CNMG and DNMG tool holders.

The TNMG16 insert can operate at cutting speeds between 200 and 300 meters per minute and feed rates from 0.1 to 0.25 mm per revolution. Its double-sided geometry with wear-resistant edges reduces vibration and enhances machining stability. Precise coding includes dimensions, coating, and dimensional tolerances to facilitate fast and accurate tool replacement. Optimized cutting parameters and proper lubrication increase the insert’s service life and improve workpiece surface quality.

| |

| jafar-esmaili-t | |

| arismantools |

| Iran |

| 66756188 |

Turning inserts

Turning inserts are precisely shaped metal components used for cutting metals in lathe machines. Standard insert dimensions typically range from 6 to 25 millimeters in length and width. Inserts are made from tungsten carbide WC, ceramics, or synthetic diamond, capable of withstanding temperatures up to 900 degrees Celsius. Their hardness ranges between 1500 to 2200 HV, enhancing tool life and cutting accuracy. Geometric angles include a main cutting angle between 0 to 15 degrees and a clearance angle of 7 degrees, which improve surface finish quality.

Inserts are usually designed with multiple cutting edges to allow quick replacement and reuse. Thickness ranges from 2 to 6 millimeters, and weight typically varies between 2 to 15 grams. For securing the insert, clamping and screw systems with precision under 0.01 millimeters are used. Coatings like titanium nitride TiN or aluminum titanium nitride AlTiN increase wear resistance and reduce friction. These features improve efficiency and reduce tool replacement costs in turning operations.

| |

| arismantools | 66756188 |

| jafar-esmaili-t |

| Iran |

TCG22 lathe insert for aluminum

The TCGT22 turning insert for aluminum is made from tungsten carbide with a surface hardness of approximately 2400HV. The cutting edge length is 12.7 mm and thickness 4.76 mm, ideal for fast and precise chip removal. A nose radius of 0.8 mm combined with a positive rake angle of 20 degrees provides smooth cutting performance and better chip control. The clearance angle of 7 degrees reduces friction and extends tool life. The TiN coating increases wear resistance and reduces metal adhesion to the tool, which is crucial in aluminum machining.

The TCGT22 insert operates at cutting speeds between 500 and 700 meters per minute and feed rates from 0.15 to 0.4 mm per revolution, enhancing productivity in aluminum machining. Its geometric design reduces vibration and improves surface finish quality. Standard coding includes precise dimensions, coating type, and dimensional tolerances for easy tool identification and replacement. Optimized cutting parameters and proper lubrication can extend tool life up to 120 minutes.

| |

| jafar-esmaili-t | |

| behradsanatpars |

| Iran |

| 021-66723241 |

INSERT

CBC turning inserts, short for Cubic Boron Carbide, are made from ultra-hard materials with a cubic crystal structure, offering a hardness of approximately 3000 to 3500 HV. These inserts are specifically designed for machining heat-resistant alloys, superalloys, and hardened steels with hardness above 60 HRC. Their exceptional wear resistance and thermal stability up to 1200°C make them ideal for dry and high-speed cutting. Standard thickness ranges from 3.18 to 6.35 mm, with relief angles between 7 and 11 degrees and nose radii from 0.2 to 1.2 mm.

CBC inserts are commonly produced in CNGA, DNGA, and SNGA geometries, optimized for effective chip breaking and vibration reduction. These inserts are typically uncoated due to the intrinsic chemical and thermal resistance of the base material. Mounting accuracy is within 0.01 mm, and their lifespan is 3 to 5 times greater than carbide inserts. In finishing operations of hardened steels or nickel-based alloys, they deliver excellent efficiency and surface quality.

| |

| behradsanatpars | 021-66723241 |

| behradsanatpars |

| Iran |

| 021-66723241 |

INSERT

Turning inserts are made of tungsten carbide or ceramic and are used for cutting and shaping metals. Typical insert sizes range from 6 to 25 millimeters with thicknesses between 3 and 6 millimeters. Common coatings include TiN, TiAlN, and Al2O3, which increase wear and heat resistance up to 1200 degrees Celsius. The hardness of these parts ranges from 1600 to 2400 Vickers, and their bending strength is approximately 3000 megapascals. The geometric design features a cutting angle between 80 and 95 degrees, reducing cutting force.

Replaceable turning inserts are used in CNC machines and manual lathes. The average weight of each insert is about 5 grams, and their precise performance enhances surface quality and tool life. International standards such as ISO and DIN are followed in manufacturing. Inserts are widely applied in automotive, steelmaking, and aerospace industries with high precision and can withstand severe mechanical loads. Prices vary between 5 and 50 dollars depending on material and coating.

.jpg?width=160&height=160&cropratio=160:160&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-99b012-images (13).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-99b012-images (13).jpg)

.jpg?width=300&height=300&cropratio=300:300&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-99b012-images (13).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-99b012-images (13).jpg) | |

| behradsanatpars | 021-66723241 |

| behradsanatpars |

| Iran |

| 021-66723241 |

CBC turning inserts

CBC Cubic Boron Carbide turning inserts are manufactured from superhard materials with a Vickers hardness between 3200 and 3500. This level of hardness is approximately twice that of tungsten carbide, making them ideal for machining superalloys, hardened steels over 55 HRC, and high-resistance cast irons. These inserts can withstand temperatures up to 1200°C and perform exceptionally well in dry cutting and high-speed operations. Their standard relief angles range from 7 to 11 degrees to maintain a balance between edge strength and smooth cutting action.

The typical thickness of CBC inserts ranges from 3.18 to 6.35 mm, and their nose radius varies between 0.4 and 1.2 mm. CBC inserts are usually uncoated, as their natural wear resistance and chemical stability eliminate the need for surface coatings. Common geometries like SNGA and CNGA are optimized for finishing hardened steels and minimizing machining vibrations, enhancing tool life and dimensional precision.

| |

| behradsanatpars | 021-66723241 |

| behradsanatpars |

| Iran |

| 021-66723241 |

INSERT

Turning inserts are replaceable cutting components used in machining tools, typically made from materials such as tungsten carbide, ceramics, CBN, or PCD. Their geometry follows ISO standard codes like CCMT, CNMG, or TNMG, each designed for specific operations. The relief angle of most inserts ranges from 5 to 11 degrees, while nose radii typically vary between 0.2 and 1.2 millimeters. Common insert thicknesses range from 2.5 to 6.35 millimeters, and their clamping systems often use screw or lever mechanisms for secure attachment.

In turning insert design, resistance to wear, high temperatures, and mechanical shocks is critical. Carbide inserts typically have a hardness around 1600 Vickers and can withstand temperatures exceeding 800 degrees Celsius. Some inserts are coated with materials such as TiN or AlTiN, which can extend tool life by up to 300 percent. Replaceable inserts improve machining accuracy, repeatability, and reduce machine downtime significantly.

.jpg?width=160&height=160&cropratio=160:160&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-download (12).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-download (12).jpg)

.jpg?width=300&height=300&cropratio=300:300&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-download (12).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-download (12).jpg) | |

| behradsanatpars | 021-66723241 |

| behradsanatpars |

| Iran |

| 021-66723241 |

Sandvik turning insert model RCGX09

The Sandvik turning insert model RCGX09 features a round design with a 9mm diameter, made from tungsten carbide with an advanced coating. The insert’s material grade is 6165, suitable for machining heat-resistant metals and superalloys. Its neutral cutting angle and two cutting edges ensure precise cutting performance and reduce cutting forces. The insert thickness is 4.76mm with a standard weight of 0.02 kg, providing enhanced stability and vibration reduction during operation.

This model has the ANSI code RCGX45A and is designed for heavy-duty and precise industrial applications. Its oxidation and wear-resistant coating increases tool life by up to 30%. The RCGX09 insert can be used in CNC machines with cutting speeds up to 250 meters per minute. The insert’s geometric design improves surface finish quality and machining efficiency. Additionally, full compatibility with various Sandvik turning machines is a key advantage of this product.

| |

| behradsanatpars | 021-66723241 |

| behradsanatpars |

| Iran |

| 021-66723241 |

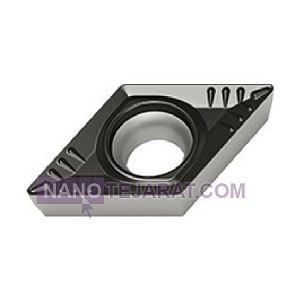

Sandvik turning insert model VBMT 16

The Sandvik VBMT 16 turning insert with code PM 4215 is made of tungsten carbide coated with titanium nitride. This insert has standard dimensions of 16x16x4 millimeters and a corner angle of 80 degrees. The TiN coating hardness reaches up to 2400 Vickers, providing wear and heat resistance up to 1000 degrees Celsius. It is designed for machining hard and alloy steels and can withstand high loads. Its high resistance increases tool life by up to 30% compared to uncoated versions.

This turning insert model features an optimized geometric design to reduce cutting forces and improve surface finish quality. Precise pitch angles reduce vibration and enhance process stability. Each piece weighs about 15 grams, and the packaging includes 10 pieces. This insert is compatible with CNC and manual lathes, suitable for precise industrial work. High durability and easy replacement are key features of this industrial tool.

| |

| behradsanatpars | 021-66723241 |

| behradsanatpars |

| Iran |

| 021-66723241 |

Sandvik RNMG Model Turning Insert

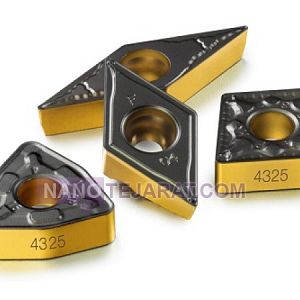

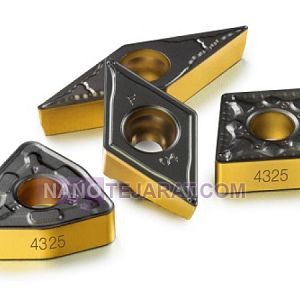

The Sandvik RNMG turning insert is a double-sided round insert, typically featuring a nominal diameter of 12.7 mm and a thickness of 4.76 mm. With a zero-degree rake angle and a radial cutting edge form, this insert is suitable for roughing to semi-finishing operations. It supports high-performance grades such as 4325 and 4425, specifically designed for machining hardened steels up to HRC 50.

The insert is usually coated with multilayer TiAlN or CVD, providing wear resistance at temperatures up to 1050°C. The tungsten carbide substrate offers a hardness ranging from 1700 to 2000 Vickers. The nose radius varies from 0.4 to 1.2 mm, directly influencing surface finish and cutting force. Its symmetrical geometry allows the insert to be reused by rotating it, increasing tool life and cost-efficiency.

.jpg?width=160&height=160&cropratio=160:160&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (23).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (23).jpg)

.jpg?width=300&height=300&cropratio=300:300&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (23).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (23).jpg) | |

| behradsanatpars | 021-66723241 |

| pichsazan |

| Iran |

| 021-55413167 |

A4 nylon insert nut

Stainless steel nylon insert nut, which is known as A2 grade, is actually produced from 316 grade steel. Nylon insert nut actually uses a polymer washer made of polypropylene or plastic in the upper part. This washer is installed on the upper edge of the steel felt bowl nut and is cut by the sharp threads of the screw when connecting the screw. The cutting of the washer by the screw causes the nut of the nylon insert nut to be connected on the surface of the attached screw with a higher tension. Therefore, the steel nylon insert nut is used in cases where the vibration in the system is high and the connection of simple screws can be opened.

| |

| pichsazan | 021-55413167 |

| mtco |

| Iran |

| 09123691065 |

RNMN Turning Insert SANDVIK

RNMN Turning Insert SANDViK | RNMN SANDVIK IRAN is a turning insert that is useable for steel industiral company so RNMN SANDVIK IRAN use with CRDNN Holder SANDVIK Moarref Tools Company as SANDVIK distributor in IRAN provide all SANDVIK productions as RNMN Turning insert SANDVIK IRAN if you want to buy RNMN SANDVIK IRAN call to moarref Tools company and download SANDVIK IRAN catalogue and choose your RNMN SANDVIK IRAN and CRDDN HOLDER SANDVIk . for informing price of RNMN SANDVIK IRAN ORGINAL or price of RNMN turning Insert send SANDVIk order to Moarref Tools company.

| |

| mtco | 09123691065 |

| kianbolt |

| Iran |

| 021-55401057 |

A4 nylon insert SS nut

Felt bowl nuts are a special type and standard of hexagonal nuts. The nut of the felt bowl is produced according to the DIN985 standard, and in the upper part, it has an edge on the holder of a plastic washer polymer. At the time of connecting the nut of the felt bowl on the screw, the screw thread of the spring washer is cut and the washer sticks on the surface of the screw. Therefore, in most applications on industrial machines with high vibrations, a felt bowl nut is used to prevent the opening of the nut connection on the screw.

| |

| kianbolt | 021-55401057 |

| mtco |

| Iran |

| 09123691065 |

TURNING INSERT

FOR MORE INFORMATION AND GET CATALOG CALL TOO MOARREF ABZAR.

| |

| mtco | 09123691065 |

| mtco |

| Iran |

| 09123691065 |

TURNING INSERT

YOU CAN GETT TURNING INSERT DNMG 150404 FROME MOARREF ABZAR

| |

| mtco | 09123691065 |