.png)

INSERT , Iran

- Price :To negotiate

- order by whatsapp

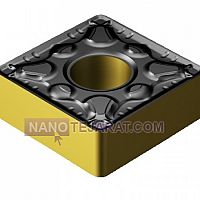

A turning insert is made from materials such as tungsten carbide, ceramics, or CBN, with a surface hardness exceeding 2500HV. The standard thickness of inserts is typically 4.76 mm, and the cutting edge length is 12.7 mm. The rake angle ranges between 5 and 25 degrees, and the clearance angle is set between 5 and 7 degrees to balance cutting efficiency and wear reduction. The insert’s nose radius usually varies from 0.2 to 1.2 mm, improving the final surface quality. Coatings like TiAlN or Al₂O₃ are applied to enhance wear and heat resistance up to 800°C. These tools are designed and coded according to ISO 1832 standards.

Turning inserts can operate at cutting speeds up to 400 meters per minute and feed rates between 0.05 and 0.5 mm per revolution. These parameters increase productivity and reduce machining time. The insert geometry includes single- or double-sided cutting edges to control cutting forces and reduce vibration. Each insert has a specific code containing geometric shape, thickness, rake angle, and dimensional tolerances. These specifications enable quick identification and replacement in production lines. Proper use of cutting parameters and lubrication can extend tool life up to 90 minutes of continuous operation.

You can order and buy INSERT from Iran by contacting us through whatsaap and email.

WEBSITE: INSERT Iran

.png)

.jpg?width=200&height=200&cropratio=200:200&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (9).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (9).jpg)

.jpg?width=200&height=200&cropratio=200:200&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (23).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (23).jpg)