INSERT , Iran

- Price :To negotiate

- order by whatsapp

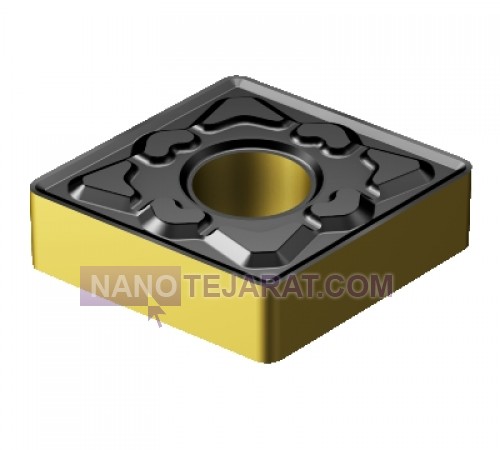

A turning insert is a replaceable cutting component designed for high-precision material removal, typically made from materials such as tungsten carbide or CBN. It features a surface hardness exceeding 2500HV, offering excellent wear resistance. The rake angle ranges from 5 to 25 degrees, while the clearance angle is typically between 5 and 7 degrees. The insert geometry includes a cutting edge length of 12.7 mm, a thickness of 4.76 mm, and a nose radius between 0.2 and 1.2 mm. Coatings such as TiAlN or Al₂O₃ are applied to reduce friction and extend tool life up to 90 minutes of continuous machining. Each insert is precisely engineered according to ISO 1832 standards to ensure consistent performance under demanding machining conditions.

Turning inserts perform efficiently at cutting speeds up to 400 meters per minute and feed rates ranging from 0.05 to 0.5 mm. They withstand thermal loads up to 800°C without compromising performance. Positive or negative rake designs optimize chip flow and machining stability. These inserts are compatible with standard holders such as CNMG, DNMG, or SNMG, used for roughing or finishing operations. Each insert is identified by a specific code that defines its shape, thickness, tolerance, and angle according to international standards. Proper use of lubrication and controlled cutting conditions enhances tool life and ensures high-quality surface finish on the workpiece.

You can order and buy INSERT from Iran by contacting us through whatsaap and email.

WEBSITE: INSERT Iran

.jpg?width=200&height=200&cropratio=200:200&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-download (9).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-download (9).jpg)

.jpg?width=200&height=200&cropratio=200:200&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (23).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (23).jpg)

.jpg?width=200&height=200&cropratio=200:200&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (8).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (8).jpg)

.jpg?width=200&height=200&cropratio=200:200&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (11).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (11).jpg)

.jpg?width=200&height=200&cropratio=200:200&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (9).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (9).jpg)