| Exporter, Wholesale, Manufacturer | |

| Azarbaijan-Tabriz | |

| +989122003350 | |

- Price :negotiated

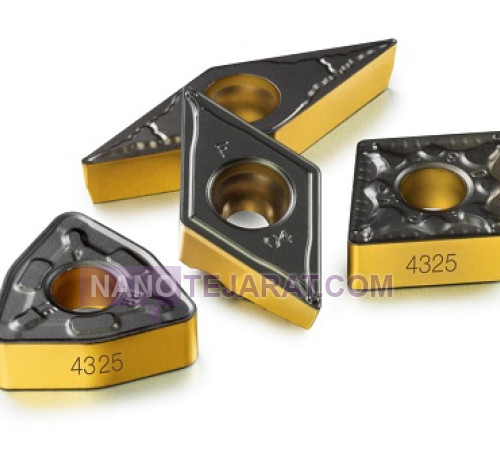

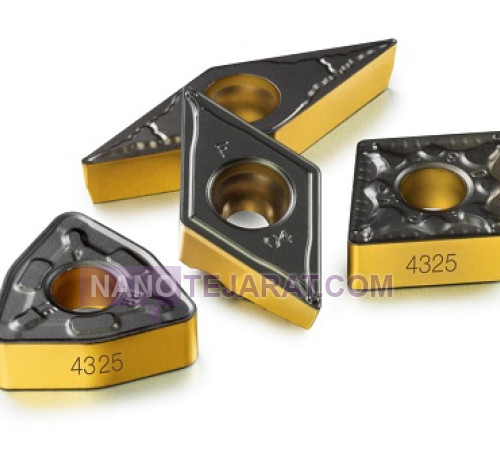

Walter CNMG190612-RM5 Diamond Turning Insert , Iran

The Walter CNMG190612-RM5 diamond turning insert is a precision-engineered square insert designed for machining hardened steels, cast iron, and heat-resistant alloys. It features dimensions of 19.05 × 6.35 mm with a 1.2 mm nose radius and conforms to the CNMG ISO standard. Its negative rake angle and balanced thickness enable stable cutting under heavy load conditions. The carbide grade used in combination with AlTiN and TiCN multilayer coatings extends tool life by up to 30% compared to similar inserts. The RM5 geometry is optimized for medium to semi-rough turning and delivers effective chip control at high speeds. This insert performs reliably in both continuous and interrupted cutting operations.

The insert’s engineering is based on precision pressing technology and nano-layered coatings, which significantly enhance its mechanical and thermal resistance. The applied cutting geometry evenly distributes stress across the cutting edge, preventing premature cracking. Its optimized corner design improves final surface finish and reduces the need for secondary polishing. Each insert weighs approximately 14.8 grams, striking a balance between mass and rigidity. Compatibility with standard ISO toolholders enables fast tool changes and boosts productivity in manufacturing environments. This model is widely used in the automotive, oil and gas, and general machining industries.

You can order and buy Walter CNMG190612-RM5 Diamond Turning Insert from Iran by contacting us through whatsaap and email.

WEBSITE: Walter CNMG190612-RM5 Diamond Turning Insert Iran

Technical and Structural Specifications of Walter CNMG190612-RM5 Diamond Turning Insert

The Walter CNMG190612-RM5 turning insert is a square-shaped tool with precise dimensions of 19.05 × 6.35 mm and a 1.2 mm nose radius, specifically designed for machining hard alloys and cast iron. Featuring a negative rake angle and standard thickness, it enables highly stable cutting performance under demanding conditions. A multilayer AlTiN and TiCN coating is applied to the surface to ensure exceptional resistance to wear and heat, withstanding temperatures up to 900°C. The RM5 geometry provides effective chip control and a superior surface finish even at high cutting speeds. The CNMG190612-RM5 insert is compatible with ISO-standard toolholders and is widely used in industrial production lines such as automotive manufacturing and heavy equipment machining.