.jpg)

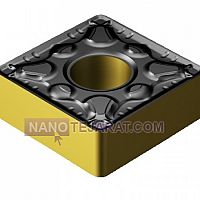

CBN turning inserts , Iran

- Price :To negotiate

- order by whatsapp

CBN turning inserts, made from cubic boron nitride, are used for machining very hard materials such as heat-treated alloy steels with hardness above 45 HRC. These inserts typically have a hardness of 4000 to 4500 Vickers and thermal resistance up to 1200°C. Their structure usually consists of a thin CBN layer about 0.5 to 1 millimeter thick over a carbide substrate. The cutting angle ranges between 5 to 7 degrees, and the nose radius is typically between 0.2 to 0.8 millimeters. Precise design enables maintaining high material removal rates at high speeds while minimizing tool wear.

CBN inserts perform optimally at cutting speeds above 200 meters per minute and are suitable for dry machining. They are used for precision tolerances of 0.01 millimeters in parts such as crankshafts, shafts, and bearings. Protective coatings like TiAlN or TiSiN improve chemical and wear resistance in some models. The tool life of CBN inserts can be up to five times longer than carbide inserts depending on process conditions. Common geometries include CNGA, DNGA, and SNGA, optimized for medium to heavy-duty applications. These tools maintain stable operation temperatures without coolant up to 1000°C.

You can order and buy CBN turning inserts from Iran by contacting us through whatsaap and email.

WEBSITE: CBN turning inserts Iran

.jpg)

.jpg?width=200&height=200&cropratio=200:200&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (10).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (10).jpg)

.jpg?width=200&height=200&cropratio=200:200&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-99b012-images (13).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-99b012-images (13).jpg)