| Atrinelevator |

| Iran |

| 021-88425461 |

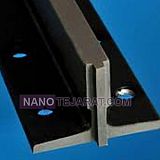

elevator rail

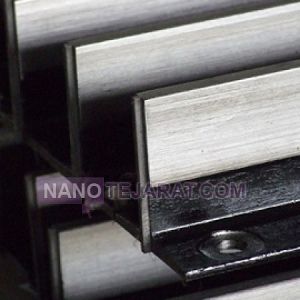

Elevator guide rails are manufactured from carbon steel grade DIN 1629 St 52.0 or equivalent per ASTM A36. The standard profile is an inverted T-shape with dimensional accuracy of ±0.15 mm and straightness under 0.5 mm per meter. Rail lengths are 5 meters cuttable and connectable up to 25 meters with linear weight of 10 to 40 kg per meter. Surface hardness is maintained at 140–180 Brinell HB for wear and fatigue deformation resistance. Maximum permissible deviation over 5 meters is 0.7 mm with local curvature below 0.25 mm per meter. These rails undergo controlled stress-relieving heat treatment and cold polishing to reduce residual stresses and extend service life.

The guide shoe contact surface is precision cold-drawn to a surface roughness of Ra 0.8 microns and coated with hard chromium. Rail joints use 15 mm steel plates with four to six Grade 12.9 bolts tightened to 450-500 Nm torque. Hot-dip galvanized coating 85 microns or electrostatic epoxy coating 70 microns is applied for corrosive and humid environments. Bending strength ranges from 350 to 1100 MPa with ultimate tensile strength of 450–550 MPa. Rails are designed to withstand dynamic loads up to 300% of rated load, vertical accelerations up to 3.5 m/s², and lateral forces up to 150 kN. Production and testing

| |

| Atrinelevator | 021-88425461 |

| behranlift |

| Iran |

| 021-87162000 |

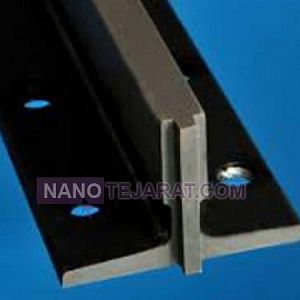

elevator rail

Elevator guide rails are manufactured from low-carbon steel grade KP80 per JIS G3101 with minimum yield strength of 360 MPa. The standard profile is an inverted T-shape with dimensional accuracy of ±0.2 mm and angular tolerance of ±0.3 degrees. Standard rail length is 5 meters seamlessly connectable up to 15 meters with linear weight of 12 to 40 kg per meter. Surface hardness is maintained at 140–170 Brinell HB for wear and deformation resistance. Maximum permissible deviation over 5 meters is 0.8 mm with local curvature below 0.3 mm per meter. These rails undergo controlled stress-relief heat treatment at 550°C to prevent installation warping.

The running surface for guide shoes is cold-drawn to a surface quality of Ra 1.2 microns with edge radii of 1.5 mm. Rail joints use 12 mm steel plates with four Grade 10.9 bolts tightened to 400 Nm torque. Hot-dip galvanized coating 80 microns or 70-micron electrostatic epoxy powder coating is applied for corrosive environments. Bending moment capacity ranges from 15 to 70 kN·m with torsional resistance up to 1000 Nm per meter. Rails are designed to withstand dynamic loads up to 200% of rated load and vertical speeds up to 12.5 m/s. Production complies with EN 81-20, ISO 7465, and GB/T 10054-2021 standards for safety and durabilit

| |

| behranlift | 021-87162000 |

| aranasansor |

| Iran |

| 021-44488073 |

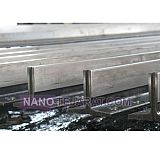

elevator rail

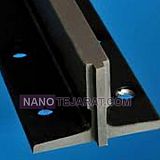

Elevator guide rails are manufactured from low-carbon steel grade Q235B or ST52 per JIS G3101 and DIN 17100 standards. The standard profile is an inverted T-shape with dimensional accuracy of ±0.25 mm. Rail lengths are 5 meters connectable up to 15 meters with linear weight of 10 to 40 kg per meter. Surface hardness is maintained at 140–180 Brinell HB for wear and deformation resistance. Maximum permissible deviation over 5 meters is 1 mm with local curvature below 0.2 mm per meter. These rails undergo normalization heat treatment for dimensional stability in temperatures from –50°C to +200°C.

The guide shoe contact surface is cold-drawn to a surface roughness of Ra 1.6 microns. Rail joints use 15 mm steel plates with 4 to 6 Grade 10.9 bolts tightened to 450 Nm torque. Hot-dip galvanized coating 80 microns or 70-micron electrostatic epoxy powder coating is applied for corrosive environments. Bending strength ranges from 350 to 1100 MPa with ultimate tensile strength of 450–600 MPa. Rails are designed to withstand dynamic loads up to 200% of rated load and vertical accelerations up to 3.5 m/s². Production complies with EN 81-20/50, ISO 7465, and GB/T 10054-2020 standards for safety and flawless performance.

| |

| aranasansor | 021-44488073 |

| aranasansor |

| Iran |

| 021-44488073 |

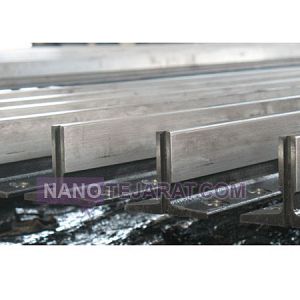

elevator rail

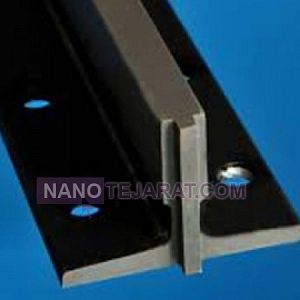

Elevator guide rails are manufactured from low-carbon steel grade Q235B or ST52 per JIS G3101 and DIN 17100 standards. The standard profile is an inverted T-shape with dimensional accuracy of ±0.25 mm. Rail lengths are 5 meters connectable up to 15 meters with linear weight of 10 to 40 kg per meter. Surface hardness is maintained at 140–180 Brinell HB for wear and deformation resistance. Maximum permissible deviation over 5 meters is 1 mm with local curvature below 0.2 mm per meter. These rails undergo normalization heat treatment for dimensional stability in temperatures from –50°C to +200°C.

The guide shoe contact surface is cold-drawn to a surface roughness of Ra 1.6 microns. Rail joints use 15 mm steel plates with 4 to 6 Grade 10.9 bolts tightened to 450 Nm torque. Hot-dip galvanized coating 80 microns or 70-micron electrostatic epoxy powder coating is applied for corrosive environments. Bending strength ranges from 350 to 1100 MPa with ultimate tensile strength of 450–600 MPa. Rails are designed to withstand dynamic loads up to 200% of rated load and vertical accelerations up to 3.5 m/s². Production complies with EN 81-20/50, ISO 7465, and GB/T 10054-2020 standards for safety and flawless performance.

| |

| aranasansor | 021-44488073 |

| faraz-andish |

| Iran |

| 021-66570886 |

elevator rail

Elevator guide rails are manufactured from low-carbon steel grade Q235B or A36 per ASTM A36/EN 10025 standards. The rail profile is an inverted T-shape with dimensional accuracy of ±0.3 mm and standard lengths of 5 meters. Linear weight ranges from 8 to 25 kg/m with flange thickness varying from 5 to 12 mm. Surface hardness is maintained at 130–170 Brinell HB for enhanced wear resistance. Maximum permissible deviation over 5 meters is 1 mm with angular tolerance of ±0.5 degrees. These rails undergo thermal normalization for uniform crystalline structure and internal stress reduction.

The contact surface with car guide shoes is cold-rolled to a surface roughness of Ra 1.6 microns. Rail joints use steel couplers and four Grade 10.9 bolts with tightening torque of 300–500 Nm. Hot-dip galvanized coating minimum 80 microns or epoxy powder coating 60 microns provides corrosion protection. Bending capacity ranges from 250 to 900 MPa with ultimate tensile strength of 370–500 MPa. Rails are designed to withstand dynamic loads up to 200% of rated load and vertical accelerations up to 2.5 m/s². Production complies with EN 81-20/50, ISO 7465, and GB/T 10054 standards for safety and flawless performance.

| |

| faraz-andish | 021-66570886 |

| ravilift |

| Iran |

| 021-66653422 |

elevator rail

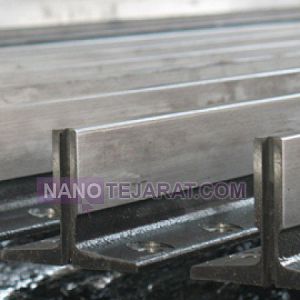

Elevator guide rails are manufactured from low-carbon steel grade Q235B per GB/T 700 or equivalent. The standard profile is an inverted T-shape with dimensional accuracy of ±0.2 mm. Rail lengths are 5 meters connectable up to 20 meters with linear weight of 8 to 30 kg per meter. Surface hardness is maintained at 130–160 Brinell HB for wear and deformation resistance. Maximum permissible deviation over 5 meters is 0.8 mm with local curvature below 0.3 mm per meter. These rails undergo stress-relieving heat treatment for dimensional stability in temperatures from –40°C to +80°C.

The guide shoe contact surface is cold-drawn to a surface roughness of Ra 1.2 microns. Rail joints use 12 mm steel plates with four Grade 10.9 bolts tightened to 400 Nm torque. Hot-dip galvanized coating 75 microns or electrostatic epoxy coating 60 microns is applied for corrosive environments. Bending strength ranges from 300 to 950 MPa with ultimate tensile strength of 410–520 MPa. Rails are designed to withstand dynamic loads up to 250% of rated load and vertical accelerations up to 3 m/s². Production complies with EN 81-20/50, ISO 7465, and GB/T 10054-2014 standards for safety and flawless performance.

| |

| ravilift | 021-66653422 |

| sahandelvtr |

| Iran |

| 021-88414621 |

elevator rail

Elevator guide rails are manufactured from low-carbon steel grade Q235B per GB/T 700 or equivalent. The standard profile is an inverted T-shape with dimensional accuracy of ±0.2 mm. Rail lengths are 5 meters connectable up to 20 meters with linear weight of 8 to 30 kg per meter. Surface hardness is maintained at 130–160 Brinell HB for wear and deformation resistance. Maximum permissible deviation over 5 meters is 0.8 mm with local curvature below 0.3 mm per meter. These rails undergo stress-relieving heat treatment for dimensional stability in temperatures from –40°C to +80°C.

The guide shoe contact surface is cold-drawn to a surface roughness of Ra 1.2 microns. Rail joints use 12 mm steel plates with four Grade 10.9 bolts tightened to 400 Nm torque. Hot-dip galvanized coating 75 microns or electrostatic epoxy coating 60 microns is applied for corrosive environments. Bending strength ranges from 300 to 950 MPa with ultimate tensile strength of 410–520 MPa. Rails are designed to withstand dynamic loads up to 250% of rated load and vertical accelerations up to 3 m/s². Production complies with EN 81-20/50, ISO 7465, and GB/T 10054-2014 standards for safety and flawless performance.

| |

| sahandelvtr | 021-88414621 |

| saman-faraz |

| Iran |

| 021-55276985 |

elevator rail

Elevator guide rails are manufactured from fine-grained non-alloy carbon steel per DIN EN 10025-2. The common grade is S355JR with a minimum yield strength of 355 MPa. Rail surfaces undergo a hardening process to achieve a hardness of 149 to 197 Brinell. The dimensional tolerance of the T-type profile, according to EN 81-20, is maintained within ±0.25 mm. The standard length per rail section is 5 meters, with production possible up to 8 meters. Rails are joined using steel fishplates and hot-dip galvanized grade 8.8 bolts. The total vertical alignment accuracy in the hoistway must not exceed 10 mm per 30 meters.

The rail profile is designed as a broad-based T-shape. This shape provides maximum bending resistance and stability against lateral forces. The contact surface for the guide shoes is finished to a surface roughness Ra below 3.2 µm. This reduces the coefficient of friction and enables silent travel. Rails are protected against corrosion by zinc flake coating or hot-dip galvanization. The protective coating thickness varies between 45 and 85 microns. The rails temperature tolerance is defined for -20 to +120 °C without deformation. Their fire resistance complies with class A1 DIN 4102.

| |

| saman-faraz | 021-55276985 |

| saman-faraz |

| Iran |

| 021-55276985 |

elevator rail

Elevator guide rails are manufactured from cold-drawn low-carbon steel with a minimum yield strength of 370 MPa. The standard profile is a T-section with precise dimensions per DIN EN 81-20. Common rail heights range from 89 to 152 millimeters. Standard rail length is 5 meters per section with a length tolerance of ±0.5 mm. Surface hardness is optimized between 150 to 190 Brinell for wear resistance. The contact surface for guide shoes is finely machined to under 3 microns roughness. Hot-dip galvanizing or thick epoxy coating provides corrosion protection for over 480 hours in salt spray tests.

The rail structure is engineered to withstand complex dynamic and static loads. The section moment of inertia ranges from 85 to 480 cm⁴ depending on rail size. These rails guarantee a deflection of less than 5 mm per 3000 mm of height. Rails are joined using steel fishplates and Grade 8.8 bolts torqued precisely to 220 Nm. An automatic leveling system during installation achieves alignment accuracy within ±0.7 mm. The rails remain dimensionally stable under thermal deformation up to 150°C. A specialized back design enables vibration damping and reduces acoustic noise below 45 dB.

| |

| saman-faraz | 021-55276985 |

| faraz-andish |

| Iran |

| 021-66570886 |

elevator rail

Elevator guide rails are made from cold-drawn low-carbon steel grade KP80 or KP100 per JIS A 5505 standard. The rail profile is an inverted T-beam shape with dimensional accuracy of ±0.5 mm. Standard rail length is 5 meters cuttable up to 8 meters with linear weight of 8 to 25 kg per meter. Surface hardness is maintained at 120–150 Brinell HB for wear resistance. Maximum permissible deviation over 5 meters is 1.5 mm with overall straightness under 0.5 mm per meter. Rails undergo stress-relief annealing to prevent installation deformation.

The contact surface with guide shoes is mechanically finished to a surface roughness of Ra 3.2 microns. Rail joints use steel plates with 4 to 6 Grade 8.8 bolts and precision coupling systems. Surface coating includes hot-dip galvanizing 85 microns or catalytic epoxy paint for humid environments. Bending resistance capacity ranges from 200 to 800 N/mm² depending on profile design. Rails are designed to withstand dynamic loads up to 150% of rated car and counterweight loads. Manufacturing complies with EN 81-20/50, ISO 7465, and GOST 51616 standards for safety and durability.

| |

| faraz-andish | 021-66570886 |

| razielevator |

| Iran |

| 021-66501609 |

elevator rail

An elevator guide rail is a hardened steel component that provides the path for the cabin and counterweight in an elevator system. Rail length is designed according to building height, ranging from 3 to 100 meters. Standard cross-section dimensions are 50×50 to 60×60 mm, with steel plate thickness of 8–12 mm. Rails are made of stainless steel or wear-resistant steel to ensure over 20 years of service life and minimal mechanical wear. Standard installation spacing is 1.0–1.2 meters, with alignment accuracy of ±1 mm to ensure smooth cabin and counterweight movement.

Rails are mounted to walls or steel frames using bolts and anchors and are in direct contact with cabin rollers or bearings. Contact surfaces are chrome-plated or wear-resistant to reduce friction and ensure smooth, quiet operation. Rails must be installed perfectly vertical and aligned to prevent vibration, noise, and wear. These rails are optimized for residential elevators up to 15 floors and commercial elevators up to 25 floors.

| |

| razielevator | 021-66501609 |

| razielevator |

| Iran |

| 021-66501609 |

elevator rail

An elevator guide rail is a hardened steel component that provides the path for the cabin and counterweight in an elevator system. Rail length is designed according to building height, ranging from 3 to 100 meters. Standard cross-section dimensions are 50×50 to 60×60 mm, with steel plate thickness of 8–12 mm. Rails are made of stainless steel or wear-resistant steel to ensure over 20 years of service life and minimal mechanical wear. Standard installation spacing is 1.0–1.2 meters, with alignment accuracy of ±1 mm to ensure smooth cabin and counterweight movement.

Rails are mounted to walls or steel frames using bolts and anchors and are in direct contact with cabin rollers or bearings. Contact surfaces are chrome-plated or wear-resistant to reduce friction and ensure smooth, quiet operation. Rails must be installed perfectly vertical and aligned to prevent vibration, noise, and wear. These rails are optimized for residential elevators up to 15 floors and commercial elevators up to 25 floors.

| |

| razielevator | 021-66501609 |

| fidar-asanbar-pasargad |

| Iran |

| 77780022 |

| |

| fidar-asanbar-pasargad | 77780022 |

| Aryabastan |

| Iran |

| 021-66286855 |

| |

| Aryabastan | 021-66286855 |