elevator rail , Iran

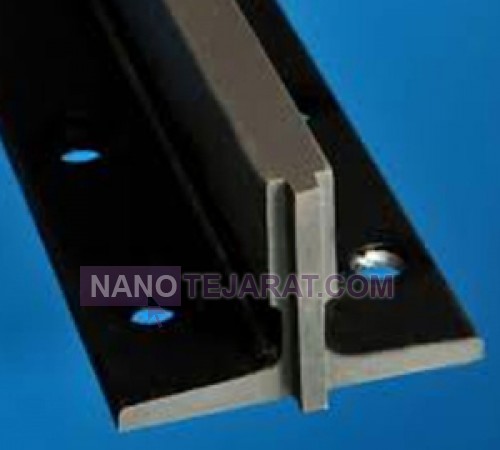

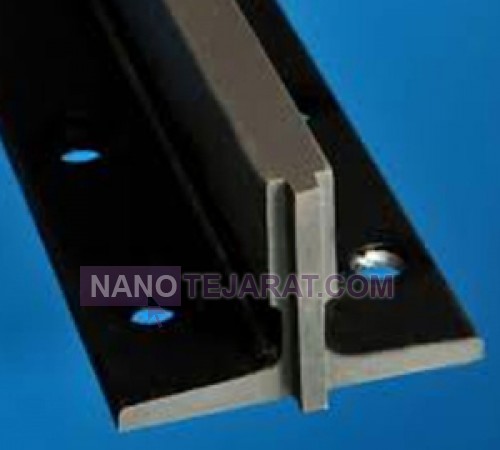

Elevator guide rails are manufactured from low-carbon steel grade Q235B or ST52 per JIS G3101 and DIN 17100 standards. The standard profile is an inverted T-shape with dimensional accuracy of ±0.25 mm. Rail lengths are 5 meters connectable up to 15 meters with linear weight of 10 to 40 kg per meter. Surface hardness is maintained at 140–180 Brinell HB for wear and deformation resistance. Maximum permissible deviation over 5 meters is 1 mm with local curvature below 0.2 mm per meter. These rails undergo normalization heat treatment for dimensional stability in temperatures from –50°C to +200°C.

The guide shoe contact surface is cold-drawn to a surface roughness of Ra 1.6 microns. Rail joints use 15 mm steel plates with 4 to 6 Grade 10.9 bolts tightened to 450 Nm torque. Hot-dip galvanized coating 80 microns or 70-micron electrostatic epoxy powder coating is applied for corrosive environments. Bending strength ranges from 350 to 1100 MPa with ultimate tensile strength of 450–600 MPa. Rails are designed to withstand dynamic loads up to 200% of rated load and vertical accelerations up to 3.5 m/s². Production complies with EN 81-20/50, ISO 7465, and GB/T 10054-2020 standards for safety and flawless performance.You can order and buy elevator rail from Iran by contacting us through whatsaap and email.

WEBSITE: elevator rail Iran

Proper Installation Method for Elevator Guide Rails

Installing elevator guide rails is a precise, step-by-step process. First, precise plumb and level lines in the elevator shaft are established using a laser or plumb wire. Support brackets are installed on the wall at a maximum spacing of 250 cm, according to technical drawings. Pre-drilled rail sections are attached to the brackets using grade 8.8 galvanized bolts and nuts. End-to-end rail connections are made using fishplates, with appropriate expansion gaps maintained. The alignment and plumb of each section are checked and adjusted immediately after installation. After full installation, a no-load test run of the cabin and counterweight is performed to check for friction and deflection. All steps must comply with standard EN 81-20 and be under the supervision of a supervising engineer.

elevator rail

Elevator

Elevator control board.

Elevator cabin

Elevator

Lift engine

Elevator cabin

elevator Parachute

Lift engine