MRL elevator , Iran

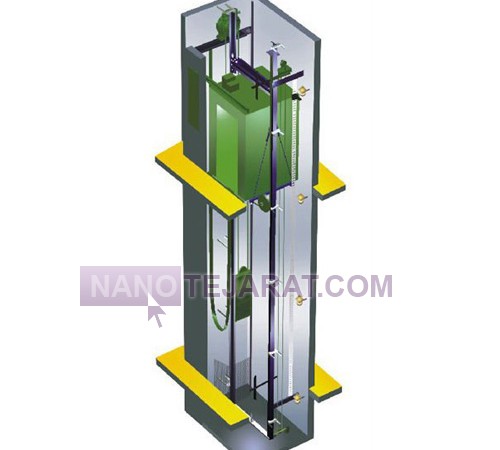

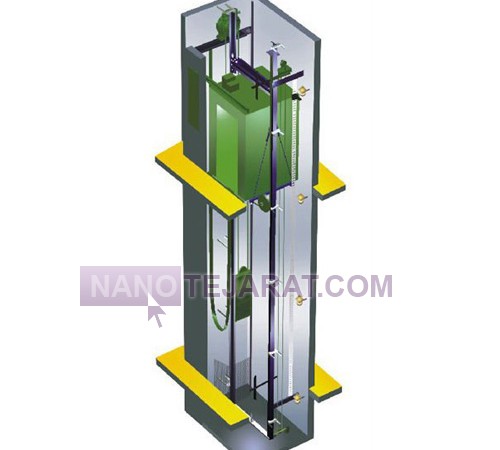

MRL elevators utilize a gearless Permanent Magnet Synchronous Motor PMSM with 5.5 to 18 kW power output. The motor is installed directly in the hoistway overhead, eliminating the need for a separate machine room. Travel speeds range from 0.5 to 4 m/s with adjustable stopping accuracy of ±3 mm. Cabin capacity spans 450 to 2000 kg for 6 to 26 passengers, designed with a 1.25 safety factor. The control system employs inverter drives with regenerative energy recovery and 95% overall efficiency. Energy consumption complies with ISO 25745-1 Class A++ standards, using 30% less energy than conventional models. All components are certified per EN 81-20/50, ASME A17.1, and ISO 22201-1 standards.

The compact structure integrates the motor directly with the traction sheave and 2:1 or 1:1 suspension systems. The cabin is constructed from lightweight aluminum panels with 40 dB acoustic insulation and Class A fire-resistant coating. Safety systems include electromagnetic safety brakes, overspeed governors, and 3D laser sensors. Automatic doors feature 120W synchronous motors and 5 mm obstacle detection capabilities. Guide rails use KP100 steel with 150 Brinell hardness and 80-micron hot-dip galvanized coating. Installation and maintenance employ IoT monitoring systems and predictive maintenance algorithms, reducing downtime by 40%. This system is ideal for mid- to high-rise buildings with machine room space limitations and high energy efficiency requirements.You can order and buy MRL elevator from Iran by contacting us through whatsaap and email.

WEBSITE: MRL elevator Iran

Advantages of Machine-Room-Less MRL Elevators

Machine-Room-Less MRL elevators are designed with the motor inside the shaft. This system provides significant space savings in the building. Lower construction costs due to the elimination of a separate machine room is a key advantage. Higher energy efficiency is achieved using permanent magnet motors and advanced drives. Flexibility in façade design is enabled as no rooftop machine room is needed. Faster and easier installation compared to traditional models is possible. Lower operational noise is experienced due to the motors placement in the shaft. They offer easy retrofit potential in existing buildings with machine room space constraints. Compliance with EN 81-20/50 standards for safety and performance is mandatory.

Lift engine

Elevator cabin

Elevator

Elevator cabin

Walking Electric

Escalator

Elevator

elevator rail

Elevator

Lift engine