- Hand tools

- Cutting and shaping tools

Diamond Cutting

Search Results For Diamond Cutting| microsanat |

| Iran |

| 021-66721823 |

Diamond cutting

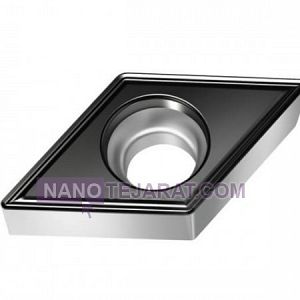

Diamond cutting tools are precisely designed to offer exceptional hardness and wear resistance, making them ideal for high-precision machining. These tools typically feature synthetic diamond inserts with hardness values up to 10,000 Vickers, enabling efficient cutting of abrasive and hard materials. The cutting edges remain sharp over time, reducing tool changes and enhancing productivity. Advanced bonding technology between the diamond and carbide substrate increases tool stability during high-speed operations. Insert sizes generally range from 3 to 20 millimeters, optimized for various applications including turning, milling, and drilling. The high thermal conductivity of diamond aids rapid heat dissipation, preventing thermal deformation and extending tool life.

The structural design of diamond cutting tools includes multi-layer coatings such as TiAlN or CVD diamond layers that enhance resistance to oxidation and wear. Insert geometries feature negative rake angles and optimized chip breakers to improve chip flow and reduce cutting forces. Diamond’s coefficient of friction is very low, usually below 0.2, preventing adhesion between tool and workpiece and improving surface finish. These tools can withstand cutting speeds above 200 meters per minute in non-ferrous material

| |

| microsanat | 021-66721823 |

| microsanat |

| Iran |

| 021-66721823 |

Diamond cutting

Diamond cutting tools are specialized instruments used in precision machining, designed for high-accuracy material removal from extremely hard surfaces. These tools consist of a durable metal base with a tip made from natural or synthetic industrial diamond, which offers exceptional hardness and outstanding wear resistance. Due to their ability to withstand high heat and pressure, diamond tools are widely used in advanced industries such as aerospace, automotive, and mold making. Their polished surface and specially engineered cutting edges significantly enhance the quality of the final surface finish, making them ideal for high-speed operations with tight tolerances.

Structurally, diamond cutting tools are available in a variety of geometries such as pointed, multi-faceted, round, or angled tips, each chosen based on the type of operation and the material being machined. The cutting angles, edge thickness, and surface coatings—such as titanium nitride or ceramic layers—play a crucial role in extending tool life and reducing friction. These tools are typically produced as replaceable inserts, standard indexable tips, or brazed tools, allowing easy installation on various machines like CNC lathes or automatic turning centers. The engineering design behind these tools ensure

| |

| microsanat | 021-66721823 |

| arismantools |

| Iran |

| 66756188 |

Diamond cutting

Diamond cutting tools are essential instruments in the machining industry, used for material removal from hard and durable materials such as hardened steel, ceramics, and heat-resistant alloys. These tools feature a tip made of natural or synthetic industrial diamond attached to a strong and sturdy metal body. Due to their high hardness, exceptional resistance to wear, heat, and mechanical pressure, they provide precise and stable performance under demanding conditions. Cutting angle design, tip geometry, and surface coating quality are key factors that enhance the efficiency and lifespan of diamond cutting tools. These features make diamond cutting tools widely applicable in sensitive industries such as aerospace, automotive, and mold manufacturing.

Structurally, diamond cutting tools are produced in various shapes and types, each selected according to the cutting operation and the material being processed. Replaceable inserts, standard indexable tips, and brazed tools are common types that can be easily mounted on CNC machines and automated equipment. Edge thickness, cutting angle, and nano or ceramic coatings significantly improve resistance and reduce friction. Strict adherence to technical and structural specifications in the design and production of diamond cutting tools

| |

| arismantools | 66756188 |

| heydarzade |

| Iran |

| 09902245921 |

Diamond cutting

Diamond cutting tools are specialized instruments designed for precise material removal from hard substances such as hardened steel, ceramics, and heat-resistant alloys. These tools feature a tip made from natural or synthetic industrial diamond attached to a sturdy metal body. Due to the diamond’s exceptional hardness, high wear resistance, and ability to withstand elevated temperatures, they deliver outstanding performance in high-speed and high-precision machining operations. The crystalline structure of diamond allows the tool to endure heavy mechanical stresses without deformation or breakage, making it widely used in advanced industries like aerospace, automotive, and mold manufacturing.

Structurally, diamond cutting tools come in various geometries such as sharp-edged, rounded, or multi-faceted designs, selected based on the machining operation and workpiece material. Cutting angle, edge thickness, and surface coatings—such as ceramic or nano layers—directly influence the tool’s durability and cutting quality. These diamonds are typically produced as replaceable inserts, standard indexable tips, or brazed tools, enabling easy installation on CNC machines and automated equipment. Adhering to precise technical and structural specifications increases tool life, imp

.jpg?width=160&height=160&cropratio=160:160&image=/admin/uploads/الماس تراشکاری-الماس سندویک-ابزار حیدر زاده-2-u1502-download (7).jpg&url=/admin/uploads/الماس تراشکاری-الماس سندویک-ابزار حیدر زاده-2-u1502-download (7).jpg)

.jpg?width=300&height=300&cropratio=300:300&image=/admin/uploads/الماس تراشکاری-الماس سندویک-ابزار حیدر زاده-2-u1502-download (7).jpg&url=/admin/uploads/الماس تراشکاری-الماس سندویک-ابزار حیدر زاده-2-u1502-download (7).jpg) | |

| heydarzade | 09902245921 |

| techno-tarash-shadmehr |

| Iran |

| 09123691065 |

Diamond cutting

Diamond cutting tools are essential components in precision machining, used for removing material from extremely hard substances such as hardened steel, ceramics, composites, and heat-resistant alloys. These tools feature a tip made from natural or synthetic industrial diamond bonded to a metal body, offering exceptional hardness and outstanding resistance to wear and high temperatures. The crystalline structure of diamond allows it to withstand extreme cutting pressures without deformation or breakage. With stable performance at high speeds, exceptional accuracy, and reduced tool replacement frequency, diamond cutting tools are ideal for advanced industries and high-volume production environments.

Structurally, diamond cutting tools are manufactured in various forms including pointed, round, multi-faceted, and angled designs to suit different machining needs. Factors such as cutting angles, edge radius, surface coatings—like nano or ceramic layers—and polishing quality directly impact the tool’s durability, surface finish quality, and overall performance. These tools are available as replaceable inserts, brazed tips, or specialized holders compatible with CNC machines and precision lathes. Attention to engineering details in their design not only improves production eff

| |

| techno-tarash-shadmehr | 09123691065 |

| heydarzade |

| Iran |

| 09902245921 |

Diamond cutting

A diamond cutting tool is one of the essential instruments in machining and material removal processes, used to create precise, smooth, and high-quality surfaces on hard metals and non-metallic materials. This tool typically consists of a sturdy metal base with an industrial natural or synthetic diamond tip. The diamond structure is designed to withstand high temperatures, continuous abrasion, and intense pressure, making it ideal for high-speed machining operations with very tight tolerances. Using diamond in cutting tools significantly increases tool life and enhances production efficiency.

From a technical perspective, diamond cutting tools feature specific and precise cutting angles tailored to the workpiece material and type of operation. The cutting edge angle, diamond geometry, surface coating, and polishing quality all play a crucial role in the tools overall performance. Depending on the application, diamond tools can be manufactured with sharp tips, round edges, multi-faceted shapes, or custom angles. They are also available in replaceable inserts, specialized holders, or brazed-tip formats, depending on the type of lathe and production requirements. These structural features in the design and manufacturing of diamond cutting tools lead to improved machining accuracy

.jpg?width=160&height=160&cropratio=160:160&image=/admin/uploads/الماس تراشکاری -الماس تراشکاری -ابزار حیدر زاده-2-u1502-75f16b-download (18).jpg&url=/admin/uploads/الماس تراشکاری -الماس تراشکاری -ابزار حیدر زاده-2-u1502-75f16b-download (18).jpg)

.jpg?width=300&height=300&cropratio=300:300&image=/admin/uploads/الماس تراشکاری -الماس تراشکاری -ابزار حیدر زاده-2-u1502-75f16b-download (18).jpg&url=/admin/uploads/الماس تراشکاری -الماس تراشکاری -ابزار حیدر زاده-2-u1502-75f16b-download (18).jpg) | |

| heydarzade | 09902245921 |

| bakutools |

| Iran |

| 09123691065 |

Walters diamond cutting

Walter diamond cutting tools are among the most advanced machining instruments, produced using modern manufacturing technologies and high-quality materials. These tools feature tips made from industrial diamond with exceptional hardness and a uniform crystalline structure, attached to a durable metal body. Their technical characteristics include outstanding wear resistance, high-temperature tolerance, and edge sharpness retention even under high-speed working conditions. Precise cutting angle design and tip geometry enhance surface finish quality and reduce cutting forces, ultimately increasing tool life and improving machining efficiency.

Structurally, Walter diamond cutting tools are manufactured as replaceable inserts and brazed tools to adapt to diverse industrial needs and allow easy installation on CNC machines. Specialized nano and ceramic coatings on the diamond surface play a significant role in reducing friction and increasing corrosion resistance. This combination of manufacturing technology and engineering design makes Walter diamond cutting tools an ideal choice for sensitive and precise applications in aerospace, automotive, and mold-making industries. Strict adherence to technical and structural standards in production ensures high quality and consistent perform

| |

| bakutools | 09123691065 |

| behine-sanat |

| Iran |

| 09902245921 |

Diamond cutting

Diamond cutting tools are essential instruments in the machining industry used for material removal from hard and durable materials. These tools feature a tip made of natural or synthetic industrial diamond attached to a strong metal body. The exceptional hardness and crystalline structure of diamond enable the tool to resist wear, pressure, and high temperatures, delivering optimal performance in high-speed and high-precision machining processes. The use of diamond cutting tools in industries such as automotive, aerospace, and mold making increases tool life and improves the surface quality of manufactured parts.

Structurally, diamond cutting tools are produced in various shapes and types, each designed according to the machining operation and the material being processed. Cutting angle, edge geometry, thickness, and surface coating type are key factors influencing the tool’s performance and durability. These tools are typically available as replaceable inserts, standard indexable tips, or brazed blades, allowing easy installation on CNC machines and industrial equipment. Strict adherence to technical and structural specifications in designing these tools enhances productivity, reduces waste, and improves the final quality of turning and machining processes.

| |

| behine-sanat | 09902245921 |