Diamond cutting , Iran

- Price :To negotiate

- order by whatsapp

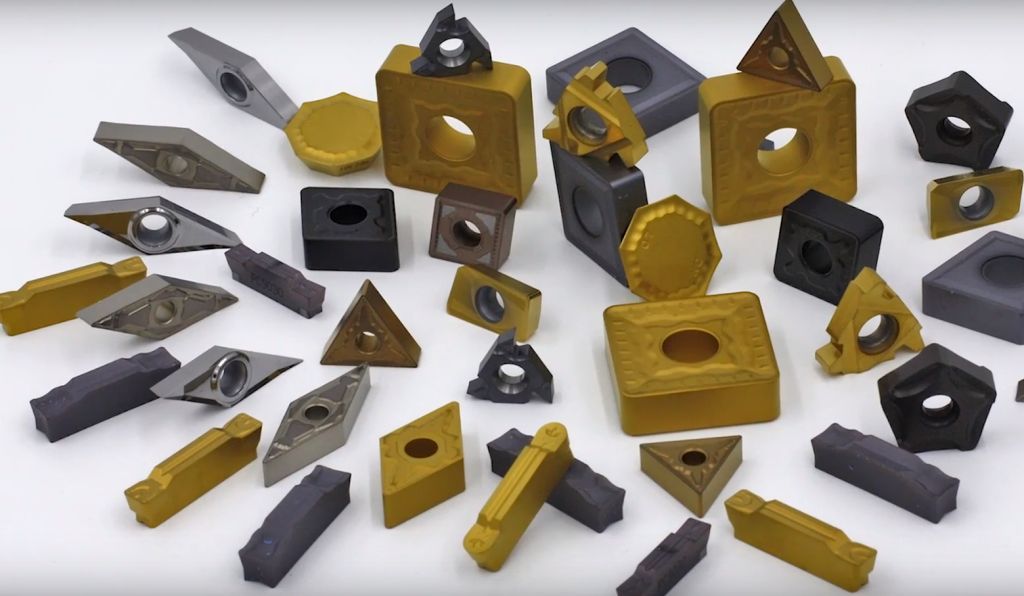

Diamond cutting tools are essential instruments in the machining industry, used for material removal from hard and durable materials such as hardened steel, ceramics, and heat-resistant alloys. These tools feature a tip made of natural or synthetic industrial diamond attached to a strong and sturdy metal body. Due to their high hardness, exceptional resistance to wear, heat, and mechanical pressure, they provide precise and stable performance under demanding conditions. Cutting angle design, tip geometry, and surface coating quality are key factors that enhance the efficiency and lifespan of diamond cutting tools. These features make diamond cutting tools widely applicable in sensitive industries such as aerospace, automotive, and mold manufacturing.

Structurally, diamond cutting tools are produced in various shapes and types, each selected according to the cutting operation and the material being processed. Replaceable inserts, standard indexable tips, and brazed tools are common types that can be easily mounted on CNC machines and automated equipment. Edge thickness, cutting angle, and nano or ceramic coatings significantly improve resistance and reduce friction. Strict adherence to technical and structural specifications in the design and production of diamond cutting tools leads to increased precision, reduced production costs, and improved surface quality of finished parts.

You can order and buy Diamond cutting from Iran by contacting us through whatsaap and email.

WEBSITE: Diamond cutting Iran

Technical and Structural Specifications of Diamond Cutting Tools

Diamond cutting tools are highly durable and precise instruments designed for machining hard and tough materials. These tools feature a tip made of natural or synthetic industrial diamond attached to a strong metal body, providing high hardness, excellent wear resistance, and the ability to withstand elevated temperatures. This allows them to perform efficiently in high-speed and high-precision machining conditions. Cutting angle design, tip geometry, and surface coating type are key factors in enhancing cutting quality and tool lifespan. Diamond cutting tools are manufactured as replaceable inserts, standard tips, or brazed tools and can be easily mounted on CNC machines and industrial equipment. Strict adherence to technical and structural specifications improves surface finish quality, increases productivity, and reduces production costs.

.jpg?width=200&height=200&cropratio=200:200&image=/admin/uploads/آچار-برای-کولت-به-صورت-تکی-CLAMPING-WRENCH-FOR-COLLET-آریسمان-ابزار-168-u1972-images (4).jpg&url=/admin/uploads/آچار-برای-کولت-به-صورت-تکی-CLAMPING-WRENCH-FOR-COLLET-آریسمان-ابزار-168-u1972-images (4).jpg)

.jpg?width=200&height=200&cropratio=200:200&image=/admin/uploads/ابزار زنده-ابزار زنده-آریسمان ابزار-168-u1972-SmartPicture (1).jpg&url=/admin/uploads/ابزار زنده-ابزار زنده-آریسمان ابزار-168-u1972-SmartPicture (1).jpg)