Diamond cutting , Iran

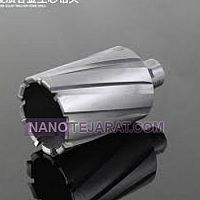

Diamond cutting tools are precisely designed to offer exceptional hardness and wear resistance, making them ideal for high-precision machining. These tools typically feature synthetic diamond inserts with hardness values up to 10,000 Vickers, enabling efficient cutting of abrasive and hard materials. The cutting edges remain sharp over time, reducing tool changes and enhancing productivity. Advanced bonding technology between the diamond and carbide substrate increases tool stability during high-speed operations. Insert sizes generally range from 3 to 20 millimeters, optimized for various applications including turning, milling, and drilling. The high thermal conductivity of diamond aids rapid heat dissipation, preventing thermal deformation and extending tool life.

The structural design of diamond cutting tools includes multi-layer coatings such as TiAlN or CVD diamond layers that enhance resistance to oxidation and wear. Insert geometries feature negative rake angles and optimized chip breakers to improve chip flow and reduce cutting forces. Diamond’s coefficient of friction is very low, usually below 0.2, preventing adhesion between tool and workpiece and improving surface finish. These tools can withstand cutting speeds above 200 meters per minute in non-ferrous materials and composites. Their performance is outstanding in industries requiring high precision such as aerospace, electronics, and automotive manufacturing.You can order and buy Diamond cutting from Iran by contacting us through whatsaap and email.

WEBSITE: Diamond cutting Iran

Technical and Structural Specifications of Diamond Cutting Tools

Diamond cutting tools combine extremely high hardness with suitable thermal resistance, making them ideal for precise machining of hard and abrasive materials. The structure of these tools includes synthetic diamond inserts that are advancedly bonded to a carbide substrate to ensure greater stability and durability. The cutting geometry is designed to reduce cutting forces and improve chip flow, while wear-resistant and oxidation-resistant coatings increase the tool’s lifespan. These features, along with standard dimensions and the ability to operate at high speeds, make diamond cutting tools highly suitable for demanding industrial applications such as aerospace, automotive, and precision parts manufacturing.