- Pneumatic tools

- Automatic Telescopic Sliding Door Operator LT-TS001(31)

- Liugong Wheel Loader ZL50C BS305.12 37C0002 Reverse a driving disc assembly (2)

- -(2)

- Wheel Loader CLG 835 Water Radiator Weichai Water cooler (1)

- Liugong Loader 46C0006 Fan SB9120A-24 The cooling fan(1)

- ZF 4WG200 Transmssion Differential bevel gear zf.4061316169(1)

- APEX Elevator Model- ELEGANCE(1)

- impact (1)

- -(1)

- -(1)

- valve(1)

- ...(1)

- piston(1)

- 41C0027 rear axle bevel gear DL1600 for Liugong CLG842 Wheel Loader(1)

- Liugong Road Roller CLG614 SP122090X1 Shangchai Fuel Pump(1)

- 42C0042 CLG835 TORQUE CONVERTER(1)

- ZF 4644159347 Variable speed control valve(1)

- Gear zf.4644308587 ZF 4WG200 Transmission(1)

- APEX Elevator Model- AC1(1)

- Electrod(1)

- -(1)

- Pneumatic Ronix Tool Nail(1)

- Compressor(1)

- projector(1)

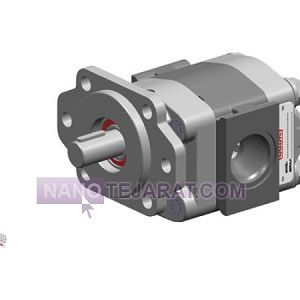

- hydraulic gear pump P7600-F140NP367 6G for Liugong ZL50C Wheel Loader 11C0007(1)

- ZF 6009054631 Transmission Computer control box (1)

- Wheel Loader ZF WG200 Gearbox Shift controller zf.0501209951(1)

- Airless Spray Equipment(1)

- impact wrenches(1)

- -(1)

- -(1)

- Electric compressor(1)

- QGBQ series cylinder(1)

- ZF TRANSMISSION 4WG200 ZF.0899005051 Torque converter(1)

- Liugong Wheel Loader CLG856 Permco P7600-F140L Pump 11C0015(1)

- WHEEL LOADER CLG816 ZL15F.2.5.1 Master driven gear(1)

- Gear pumps zf.0899005052(1)

- wheel loader clg856 ZFWG200 Gearbox Filters zf.0750131053(1)

- oil suction(1)

- -(1)

- -(1)

- ...(1)

- SR3 series solenoid Valve(1)

- Cummins piston rings 6CT.3802429 for Liugong CLG856 Wheel Loader(1)

- Hand tools

- Hydraulic tools

- Mini Impact Wrench(33)

- Impact Wrench(13)

- Digital Torque Wrench(8)

- hydraulic connections(8)

- Hydro electric pressure switch Bosch Rexroth USA(3)

- ClassicTorqueWrench(3)

- Pressure reducing valves, sandwich module, direct operated(2)

- Electronic Caliper(2)

- Protractor(2)

- ElectricalNutrunner(2)

- ALPHAIR Pneumatic Actuator(1)

- اکچویتور pneumatic actuators(1)

- Bosch Rexroth USA HED 5 Hydro electric pressure switch(1)

- Hydro electric piston type pressure switches HED 1 (1)

- Hydro electric piston type pressure switches HED 1(1)

- Pressure reducing valve, direct operated(1)

- Pressure reducing valve, direct operated(1)

- Pressure reducing valves, sandwich module, direct operated(1)

- Pressure reducing valves, sandwich module, direct operated(1)

- Pressure reducing valves, sandwich module, direct operated(1)

- Pressure reducing valves, sandwich module, direct operated(1)

- Pressure reducing valves, sandwich module, direct operated(1)

- vickers proportional directional valve(1)

- rexroth pressure switch hed 4 (1)

- Protractor(1)

- Injector(1)

- power pack and unit design and construction(1)

- hydraulic directional valves of Hawe(1)

- Pneumatic Actuator of Alphair (1)

- Hydraulic Gear Pumps of GPM(1)

- ALPHAIR Pneumatic Actuator(1)

- ALPHAIR Pneumatic Actuator(1)

- Hydro electric piston type pressure switches HED 1(1)

- Pressure reducing valve, direct operated(1)

- Pressure reducing valve, direct operated(1)

- Pressure reducing valve, direct operated(1)

- Pressure reducing valves, sandwich module, direct operated(1)

- Pressure reducing valves, sandwich module, direct operated(1)

- Pressure reducing valves, sandwich module, direct operated(1)

- Pressure reducing valves, sandwich module, direct operated(1)

- Pressure reducing valves, sandwich module, direct operated(1)

- Bosch Rexroth Proportional Directional Valve (1)

- vickers proportional directional control valve (1)

- Chlorination and disinfection systems(1)

- suction filters(1)

- lever directional valve(1)

- Design and manufacture of hydraulic cylinders(1)

- ALPHAIR Pneumatic Actuator(1)

- TURBO(1)

- HED 2 Hydro electric pressure switch Bosch Rexroth USA(1)

- Hydro electric piston type pressure switches HED 1(1)

- Pressure reducing valve, direct operated(1)

- Pressure reducing valve, direct operated(1)

- Pressure reducing valve, direct operated(1)

- Pressure reducing valves, sandwich module, direct operated(1)

- Pressure reducing valves, sandwich module, direct operated(1)

- Pressure reducing valves, sandwich module, direct operated(1)

- Pressure reducing valves, sandwich module, direct operated(1)

- Pressure reducing valves, sandwich module, direct operated(1)

- rexroth proportional directional valve(1)

- rexroth proportional directional control valve(1)

- Electronic Outside Micrometer(1)

- Wastewater Treatment package(1)

- electric valve(1)

- lever directional valves of Hawe(1)

- شیر برقی REXROTH 4WEH32(1)

- پمپ دنده ای GPM Hydraulic Pump(1)

- Hydro electric pressure switch Bosch Rexroth USA HED 8(1)

- Hydro electric piston type pressure switches HED 1 4X(1)

- Hydro electric piston type pressure switches HED 1(1)

- Pressure reducing valve, direct operated(1)

- Pressure reducing valve, direct operated(1)

- Pressure reducing valves, sandwich module, direct operated(1)

- Pressure reducing valves, sandwich module, direct operated(1)

- Pressure reducing valves, sandwich module, direct operated(1)

- Pressure reducing valves, sandwich module, direct operated(1)

- Pressure reducing valves, sandwich module, direct operated(1)

- Pressure reducing valves, sandwich module, direct operated(1)

- vickers proportional directional control valve (1)

- rexroth proportional directional control valve(1)

- Design and manufacture hydraulic systems(1)

- Hydraulic Proportional Directional Valves of ATOS(1)

- Nuts,Bolts and Screws

- Cutting discs

- Welding and Soldering

- Electrode(4)

- Equipment(4)

- electrode(4)

- electrode(3)

- esab electrode(3)

- Connection head Fittings(2)

- Welding Tables(2)

- Electric Power Tools(1)

- Stainless steel electrode(1)

- Boost Star430(1)

- electrode sorex(1)

- electrode sorex(1)

- Electric drills(1)

- electrofusion(1)

- CNC-Milling(1)

- Electrofusion welding machine(1)

- Welding electrode(1)

- GMAW Wires(1)

- Automation(1)

- Cast Iron Electrode(1)

- Welding machine CD-200E(1)

- Steel Wire rope and accessories

- steel Wire rope(16)

- non-rotating ungalvanized steel wire rope(7)

- chain connection(7)

- connector(7)

- Electric winch(7)

- electric hoist(5)

- Sling(4)

- connecting link(3)

- Hoists(3)

- elevator guide shoe(3)

- connection link(2)

- elevator sliding guide shoe(2)

- Single phase electric hoist(2)

- Connecting link(2)

- elevator traction machine(2)

- 6*19S+FC wire rope(1)

- verotop P (1)

- Chain Link Fence PVC Coated(1)

- Power Winches(1)

- Harnesses(1)

- grade 80 connecting link(1)

- Electric chain hoist(1)

- KITO ELECTRIC HOISTS(1)

- non_rotating compacted wire rope(1)

- elevator steel wire rope(1)

- Tire protection chains(1)

- Electric Crane(1)

- ٍelectric hoist(1)

- TITAN Electric Trolley (1)

- Connecting Link(1)

- 1ton electric hoist(1)

- Miniature electric hoist (1)

- Miniature electric hoist (1)

- chain connecting link(1)

- Electrical tools(1)

- Compact rock cutting wire(1)

- Compact non-rotating rope(1)

- Stainless steel 316 Wire Rope 5 mm(1)

- Stainless steel 316 Wire Rope 6 mm(1)

- winch anchor chain(1)

- dia10 connecting link(1)

- lifting chain(1)

- Wire Rope 6X19 IWRC(1)

- Steel Wire Rope(1)

- Steel Wire Rope 22 6x19(1)

- Rotation Resistant Rope 10 19*7 - 35*7 (1)

- Rotation Resistant Rope 18 19*7 - 35*7 (1)

- Steel Wire Rope 14 6x37(1)

- Elevatore Steel Wire Rope 6.5 mm 8x19(1)

- Elevatore Steel Wire Rope 12 mm 8x19(1)

- Elevatore Steel Wire Rope 11 mm FC 8x19(1)

- dia8 connecting link(1)

- 600 KG electric winch(1)

- 5 ton electric hoist(1)

- chinese tirfor(1)

- 12V 10,000 lbs Front-Mount Electric Winch for Vehicles(1)

- Electric Winch 750 to 1500 kg – 100 Meter Lifting Height(1)

- 1-Ton Dual-Function Electric Hoist – Kito Design(1)

- 3-Ton Dual-Function Electric Chain Hoist – KITO(1)

- Drilling ropes(1)

- Endless Chain Electric Blocks(1)

- 19*7-20.0 non-rotating galvanized steel wire rope(1)

- 18*7-14.0 steel wire rope(1)

- 6*36SW+IWRC steel wire rope(1)

- Gabion(1)

- Chains(1)

- Protection(1)

- Electric Crane(1)

- KITO ELECTRIC HOISTS(1)

- KITO ELECTRIC HOISTS(1)

- 26*6 Compacted wire ropde(1)

- connections(1)

- connecting link(1)

- Electric Crane(1)

- Tree Phases Electric Hoist(1)

- Electric Hoist(1)

- 2 ton electric hoist(1)

- Miniature electric hoist (1)

- Miniature electric hoist (1)

- Connections(1)

- Electrical tools(1)

- Electric winch(1)

- Stainless steel 316 Wire Rope 4 mm(1)

- Stainless steel 316 Wire Rope 8 mm(1)

- 1200 kg electric winch(1)

- hook and hook turnbuckle(1)

- rope(1)

- Wire Rope 6X37 IWRC(1)

- Steel Wire Rope 16 6x19(1)

- Steel Wire Rope 24 6x19(1)

- Rotation Resistant Rope 12 19*7 - 35*7 (1)

- Steel Wire Rope 8 6x37(1)

- Steel Wire Rope 16 6x37(1)

- Elevatore Steel Wire Rope 8 mm 8x19(1)

- Elevatore Steel Wire Rope 13 mm 8x19(1)

- Elevatore Steel Wire Rope 12 mm FC 8x19(1)

- 1 ton electric winch(1)

- 3ton toyo electric hoist(1)

- sheet clamp(1)

- 4d electric hoist(1)

- 12V 12000 LBS Front-Mounted Electric Winch for Vehicles(1)

- 2 ton chain electric hoist with trolley(1)

- 1-Ton 4-Way Electric Hoist – KITO(1)

- 3-Ton Electric Hoist – 4-Function KITO (1)

- Carbon spring steel wire (1)

- chains connecting-ring(1)

- 1*19 steel wire rope(1)

- 6*19W+IWR hoisting steel wire rope(1)

- Chain Link Fence(1)

- Chain Slings(1)

- Eyehook(1)

- connection link(1)

- KITO ELECTRIC HOISTS(1)

- KITO ELECTRIC HOISTS(1)

- Gustav Wolf elevator steel wire rope(1)

- wire rope connections(1)

- Connections(1)

- Tree Phases Electric Hoist/Wire Rope(1)

- Hand winch with friction brake(1)

- Multi task electric hoist(1)

- Miniature electric hoist (1)

- KITO ELECTRIC HOISTS(1)

- Electric hoist(1)

- 4.8 Compacted steel wire rope(1)

- 4D electric hoist(1)

- Hot dip galv anchor chain(1)

- Stainless steel Wire Rope 3 mm(1)

- Stainless steel 316 Wire Rope(1)

- size 8 connecting link(1)

- galvanized excavating wire rope(1)

- Crane Wire Rope(1)

- Electric and manual crane chains(1)

- Steel Wire Rope 18 6x19(1)

- Rotation Resistant Rope 6 19*7 - 35*7 (1)

- Rotation Resistant Rope 14 19*7 - 35*7 (1)

- Steel Wire Rope 10 6x37(1)

- Steel Wire Rope 18 6x37(1)

- Elevatore Steel Wire Rope 10 mm 8x19(1)

- Elevatore Steel Wire Rope 8 mm FC 8x19(1)

- Elevatore Steel Wire Rope 13 mm FC 8x19(1)

- M10 connecting link(1)

- construction winch(1)

- metal sheet double clamp(1)

- 12V 6000lbs Electric Winch for Vehicles(1)

- 12V Electric Front Winch 3000LBS(1)

- TOYO 3 ton electric hoist(1)

- 2-Ton Dual-Function Electric Hoist – KITO(1)

- 5-Ton Dual-Function Electric Hoist – KITO(1)

- 6*37 steel wire rope sling(1)

- 6*37S+IWR wire rope(1)

- steel strand(1)

- Convetionel Kg Barbed Wire(1)

- Mechanical Winch(1)

- Personal Protective Equipment(1)

- Electric Chain Hoist with manual Trolley(1)

- KITO ELECTRIC HOISTS(1)

- KITO ELECTRIC HOISTS(1)

- elevator steel wire rope(1)

- connections(1)

- Steel Wire RopeUngalvanized and Galvanized(1)

- electrical hoist(1)

- new generation electric hoist(1)

- Electric Hoist(1)

- 35 ton electric hoist(1)

- Miniature electric hoist (1)

- Miniature electric hoist (1)

- CM ELECTRIC HOISTS(1)

- ELECTRIC CHAIN HOIST(1)

- Electric hoist(1)

- tower crane wire rope(1)

- Carbon steel turnbuckle(1)

- Stainless steel 316 Wire Rope 2 mm(1)

- 6mm connecting link(1)

- 20mm non-rotating wire rope(1)

- ship and barge anchor chain(1)

- Endless Webbing Sling Lifting Belt(1)

- Galvanized Steel Wire Rope(1)

- Steel Wire Rope 20 6x19(1)

- Rotation Resistant Rope 8 19*7 - 35*7 (1)

- Rotation Resistant Rope 16 19*7 - 35*7 (1)

- Steel Wire Rope 12 6x37(1)

- Steel Wire Rope 20 6x37(1)

- Elevatore Steel Wire Rope 11 mm 8x19(1)

- Elevatore Steel Wire Rope 8 mm FC 8x19(1)

- Non-rotating Wire Rope(1)

- 2 ton electric hoist(1)

- Compacted Wire Roe(1)

- VITAL 1600 kg lever block(1)

- 12V 8000LBS Front-Mounted Electric Winch(1)

- Disan Electric Winch – 500 to 1000 kg Capacity(1)

- ELEPHANT electric hoist(1)

- 2-Ton Four-Function Electric Hoist – KITO(1)

- 5-Ton Electric Chain Hoist – 4-Way KITO(1)

- Drilling ropes(1)

- Electric Wire Rope Hoist(1)

- 8*19s-8.0 steel wire rope(1)

- Valves

- Spring

- Electrical tools

- mashad tadbir(3)

- drill(3)

- jigsaw(2)

- electrical tools(2)

- 2РМГ30Б32Ш1Е2 Electrical Connector Hermetic(1)

- Junction Box(1)

- Electro CHIPPING HAMMER(1)

- RONIX TOOLS(1)

- РС4ТВ PC4TB Electronic Connector(1)

- Electric screwdriver(1)

- Angle Grinder(1)

- Airless Spray device(1)

- RONIX TOOLS(1)

- Electrical Connectors Made in Russia(1)

- Screwdrivers(1)

- Airless Spray device(1)

- Cat5e connectors(1)

- Electric CHIPPING HAMMER(1)

- Electric paint sprayer(1)

- LED board

- GPS

- Closed circuit television

- Electric generator

- Audio equipments

- Electric parts

- Cable, Wire and Accessories

- UPS and Battery

- Bulb and Lighting equipment

- Bus and Minibus

- Car

- Truck and minitruck

- Construction Machinery

- Spare parts for construction machinery(47)

- Appliances construction machinery(8)

- Nail construction machinery(6)

- construction machinery spare parts(6)

- hydraulic pump for construction machinery(6)

- Idler(5)

- Chain construction machinery(5)

- spare parts(4)

- Construction machinery engine components(4)

- chinese construction machinery wheel loaders caliper kits(4)

- injector unit(3)

- motor parts of construction machinery(3)

- construction machinery filters(3)

- Piston Fit(3)

- Sensor(3)

- komatsu construction machinery spare parts(2)

- construction machinery cutting edge(2)

- Chinese Constructiion machinery Engine Motors spare parts(2)

- Injection Parts(2)

- Connecting Rod Bush(2)

- construction machinery filters(2)

- friction disc for allison(2)

- friction disc gear(2)

- friction disc for rich-kesler(2)

- friction disc for jhondear(2)

- construction machinery filter(2)

- construction machinery mann(2)

- friction disc ,piate(2)

- Unit injection(2)

- Engine parts for construction machinery(1)

- constructin machinary spare parts(1)

- FP disel products(1)

- construction machinery spare parts(1)

- construction machinery spare parts(1)

- construction machinery spare parts(1)

- injector pump(1)

- cummins products(1)

- construction machinery cutting edge(1)

- construction machinery filter(1)

- construction machinery engine parts(1)

- construction machinery cutting edge(1)

- SDLG construction machinery(1)

- construction machinery spare parts(1)

- CONSTRUCTION MACHINERY SPARE PARTS(1)

- Cylinder Block(1)

- friction graphit komatsu(1)

- friction disc z.f (1)

- friction disc for komatsu(1)

- friction disc bronze for kararo-case(1)

- friction disc(1)

- friction disc ,friction plate(1)

- friction clutch for komatsu(1)

- friction disc(1)

- friction disc for z.f(1)

- friction disc for tank militray(1)

- friction disc terex(1)

- friction disc for komatsu(1)

- Impact Brake Press(1)

- Batching Plant friction brake(1)

- Terex friction(1)

- Unit injection scania(1)

- friction plate(1)

- NEW HOLLAND LB95B , B90B CONNECTING ROD (1)

- Types of superchargers for construction machinery: loaders, bulldozers, graders, and excavators(1)

- Supplying construction machinery parts(1)

- NEW HOLLAND E265BJ CONNECTING ROD BEARING(1)

- Industrial, construction, and agricultural hydraulic pumps(1)

- CONNECTING ROD FOR HYUNDAI EXCAVATOR(1)

- Excavator Kato Friction Disc(1)

- Electric Parts(1)

- Alto friction disc for Dana Spicer(1)

- Cylinder Liner Fit(1)

- VOLVO BM 4500 wheel bearing(1)

- Track Chain(1)

- ITR construction machinery sprocket(1)

- Sprocket(1)

- Hydraulic Orange Peel Grab(1)

- Spare parts for construction machinery(1)

- Multiple valve(1)

- constructin machinary engine(1)

- construction machinery spare parts(1)

- construction machinery spare parts(1)

- Volvo Penta TAMD102A 270124 Connecting Rod Bearing(1)

- construction machinery roller(1)

- construction machinery filter(1)

- construction machinery spare parts(1)

- R210, R290, R320Track Roller for Excavator Parts Hyundai (1)

- construction machinery spare parts(1)

- Chinese construction machinery spare parts(1)

- construction machinery spare parts(1)

- Friction Disc(1)

- friction graphit volvo(1)

- friction disc for marine(1)

- friction disc for crane(1)

- friction disc gerarbox caterpillar(1)

- friction disc for lift komatsu(1)

- friction discplate(1)

- friction disc for marine(1)

- friction disc for cater pillar(1)

- friction molybdenum(1)

- friction disc paper for allison(1)

- friction disc for kararo(1)

- Construction machinery accumulator(1)

- LB95B CONNECTING ROAD BUSH(1)

- friction disc Batching Plant(1)

- friction disc paper terex(1)

- Injection Parts(1)

- Actuator kit(1)

- Fiat Allis 605 & Fiat Allis 545 Ring set(1)

- NEW HOLLAND B90B , LB95B SCREW CONNECTING ROD(1)

- Construction machinery chains(1)

- Victor cover O-ring(1)

- electrical system of a Komatsu excavator(1)

- Connecting rod bushing for New Holland B110 and B115(1)

- Komatsu dump truck injector pump(1)

- injector for hyundai excavator(1)

- connecting rod for hyundai wheel loader(1)

- Construction spare parts(1)

- Backhoe loader CUKUROVA friction brake(1)

- Actuator(1)

- Carrier Roller(1)

- Track Chain without Shoes for Construction Machinery(1)

- construction machinary engine part(1)

- Solenoid(1)

- Piston ring(1)

- constructin machinary spare parts(1)

- Chinese construction machinery(1)

- connecting rod bush(1)

- injector pump(1)

- construction machinery filter(1)

- construction machinery spare parts(1)

- construction machinery filters(1)

- construction machinery spare parts(1)

- construction machinery spare parts(1)

- construction machinery cutting edge(1)

- construction machinery filter(1)

- construction machinery spare parts(1)

- Used Cat Grader(1)

- construction machinery spare parts(1)

- construction machinery spare parts(1)

- construction machinery(1)

- Spare Part For Construction Machinery(1)

- CHINESE GRADER TRANSMISSIONS GEAR SELECTOR(1)

- 180-200 friction bronze z.f(1)

- friction disc plate(1)

- friction disc,friction plate(1)

- friction disc gear(1)

- friction disc paper(1)

- friction disc for komatsu(1)

- friction graphite Damptrak Caterpillar wheel , Turks(1)

- friction disc for z.f.200-180(1)

- friction disc for td-25(1)

- friction disc Transmission Clark(1)

- friction disc for marine(1)

- friction disc Batching Plant(1)

- friction cork(1)

- Injector copper washer(1)

- Impact press pad(1)

- Fiat Allis 645 Ring Set(1)

- FIAT ALLIS FR15 CONNECTING ROD ENGINE BEARING(1)

- Construction machinery sunroofs(1)

- NEW HOLLAND B90B , LB95B CONNECTING ROD BEARING(1)

- Victor cover O-ring(1)

- Construction machinery bearings(1)

- Loader HWL65 Friction Plate(1)

- Construction machinery accumulator(1)

- Electric hydraulic valve(1)

- volvo L90 electric parts(1)

- NDC Engine Bearing(1)

- hyundai 760 friction graphite(1)

- Pins and Bushings(1)

- construction machinary spare part(1)

- constructin machinary spare parts(1)

- Caterpillar products(1)

- construction machinery spare parts(1)

- Electrical solenoid (1)

- construction machinery spare parts(1)

- DM products(1)

- construction machinery spare parts(1)

- construction machinery spare parts(1)

- construction machinery wheel(1)

- injection nuzzle(1)

- construction machinery spare parts(1)

- construction machinery chain(1)

- construction machinery spare parts(1)

- construction machinery spare parts(1)

- construction machinery under carriage(1)

- Chinese Constructiion machinery Engine Motors spare parts(1)

- Cylinder Head(1)

- friction bronze(1)

- friction disc gearbox bronze(1)

- friction disc for allison(1)

- friction disc for dosan z.f.(1)

- friction disc(1)

- friction disc,plate(1)

- friction disc(1)

- friction disc for hyundai(1)

- friction disc for tank militray(1)

- friction disc bronze(1)

- friction disc zf 190-210(1)

- friction disc for newholland(1)

- friction disc Batching Plant(1)

- friction disc Batching Plant(1)

- Perkins Injection pump(1)

- Steel factory industrial brake pads(1)

- Fiat Allis 645 Connecting Road Bush(1)

- Injector pump components(1)

- self-acting relief(1)

- NEW HOLLAND B110 , B115 CONNECTING ROD BUSH(1)

- connecting rod bolt(1)

- tractor(1)

- Grader AG180D1 friction Brake (1)

- Nozzle injection(1)

- piston ring(1)

- VOLVO BM 4400 loader electric parts(1)

- undercarriage(1)

- ITR Construction Machinery Fork(1)

- Bolts and Nuts(1)

- Operating room equipment

- Laboratory equipment

- Medical equipment

- Specialized medical equipment

- Electrocardiogram ECG(3)

- Electro-Shock(3)

- Patients electric bed. Three punch metal punches with German bad side(2)

- Electrosurgical devices(2)

- Patients electric bed(2)

- Electric wheelchair(1)

- Electric beds for patients(1)

- 3 section patient bed(1)

- Surgical electrocautery tip(1)

- electroshock(1)

- electroshock (1)

- electroshock(1)

- RF Fractional CO2 Laser System(1)

- Suction desktop(1)

- Electric patient Bed(1)

- Fully positioned electric beds(1)

- Suction(1)

- electroshock(1)

- suction(1)

- Electric beds for patients(1)

- Electric beds for patients(1)

- Electric Wheel Chair(1)

- The patients electric bed can be washed with abs(1)

- CT(1)

- electroshock(1)

- PRIMEDIC electroshock(1)

- atmos -medela suction(1)

- Electric beds salons(1)

- Electric beds for patients(1)

- -(1)

- Radiology(1)

- electroshock(1)

- PRIMEDIC electroshock(1)

- Dental equipment

- Radiology ultrasound machines

- Laser

- Swimming pool and Equipment

- Heater, Cooler and Conditioner

- Oil-Inject Rotary Screw Compressors (6)

- wall hung boiler(1)

- Fara Electric industrial electronic descaler model EDS300(1)

- wall hung boiler(1)

- Fara Electric industrial electronic descaler model EDS200(1)

- Fara Electric industrial electronic descaler model EDS150i(1)

- Fara Electric industrial electronic descaler model EDS150(1)

- Demir Sun Classic 140 Double-Sided panel radiator(1)

- kitchen equipment

- Construction Services

- Doors and Windows

- Fabricated structures and Panels

- Stone, Ceramic and Tile

- Faucet

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Pipe

- Construction Materials

- Elevator and Lifting equipments

- Elevator load weighing device(5)

- elevator control panel(3)

- elevator motor(1)

- Dictator(1)

- light curtain(1)

- female contact(1)

- male contact(1)

- Electric escalator and walk(1)

- elevator control panel(1)

- three-parts Elevator Intercom, Elevator Intercom System, Elevator Phone(1)

- right 2 panel female contact holder(1)

- Walking Electric(1)

- elevator control panel(1)

- Weighting devices and laod sensor(1)

- male contact holder(1)

- Elevator door(1)

- Elevator load sensor (1)

- Machinery spare parts

- Packing Machines

- Plastic Injection Machine

- plastic injection machine(4)

- machinery manufacturing factory pp PVC pet PS to (2)

- machinery manufacturing factory pp.PVC.pet.PS to the next (1)

- Foam sheet production machinery(1)

- The production of aluminum(1)

- Plant Container Production Line(1)

- machinery manufacturing factory pp PVC pet PS to (1)

- machinery manufacturing factory pp.PVC.pet.PS to (1)

- Disposable container production machinery(1)

- Plastic sheet production line(1)

- Plant Container Production Line(1)

- machinery manufacturing factory pp.PVC.pet.PS to the next (1)

- Bread Production Line(1)

- Disposable container production machinery(1)

- lain pp.PVC.pet.PS (1)

- machinery manufacturing factory pp.PVC.pet.PS to the (1)

- Plant production line and plastic crockery(1)

- Construction Machinery

- Food industry Machines

- Forging Machinery

- Plastic & Rubber Machine

- Construction Machinery

- Mining Machinery

- Agriculture & Farming Machinery

- Other industrial Machines

- Water treatment equipment

- Heater, Cooler and equipment

- Decoration

- Hi-Fi system

- Kitchen Appliances

- Electric tools

- Sewing Machine

- Packing Box

- Printing & Packing Services

- Printing Machinert

- Copier

- Pump

- Fruit and Vegetable Washer Machine(3)

- electro pump(2)

- Inverters(1)

- Sewage Electropump(1)

- Ice Cream Crates Washer Machine(1)

- BULK MILK COOLER(1)

- Electromotor(1)

- multi functional key(1)

- Axial and Mixed Flow Electro pump(1)

- Pallet Washer Machine(1)

- Ferguson tractor hydraulic pump repair(1)

- Double Suction Pump(1)

- Bottle Sterilizer(1)

- Submersible Electropumps(1)

- Utensil washer machine(1)

- Testing Equipment

- Industrial Electrical Equipment

- Lifting Equipment

- Refrigerating Equipment

- Air Conditioning Equipment

- -(3)

- -(2)

- -(2)

- -(2)

- -(1)

- -(1)

- -(1)

- -(1)

- -(1)

- -(1)

- -(1)

- -(1)

- electric valve coil(1)

- Shokoh Electronics GW 3 A4 Air Pressure Switch(1)

- Shokouh Electronics Dual-Fuel Relay Model G811-UV(1)

- Jets Fan(1)

- coaxial pipe connector(1)

- -(1)

- Siemens QRA2 Burner Flame Detector Photo Cell(1)

- -(1)

- -(1)

- -(1)

- -(1)

- -(1)

- -(1)

- -(1)

- -(1)

- Shokoh Electronics GW 10 A4 Air Pressure Switch(1)

- Shokho Electronic EB1 Ignition Transformer(1)

- Active Carbon Filter(1)

- تایمر(1)

- -(1)

- -(1)

- -(1)

- -(1)

- -(1)

- -(1)

- -(1)

- -(1)

- -(1)

- -(1)

- Shokoh Electronics GW 50 A4 Air Pressure Switch(1)

- Shokho Electronics photocell model UVZ780 red(1)

- voltage Protector (1)

- -(1)

- -(1)

- -(1)

- -(1)

- -(1)

- -(1)

- -(1)

- -(1)

- -(1)

- -(1)

- -(1)

- Gas-oil electric valve(1)

- Shokoh Electronics GW 150 A4 Air Pressure Switch(1)

- Landis Siemens photocell model QRB3(1)

- coaxial pipe connector(1)

- -(1)

- -(1)

- Industrial Services

- Industrial Tools & Parts

- Diesel Engine Parts Diesel Parts(6)

- ---(1)

- M6*10 10B21 zinc plated special T slot screws with slotting on end of shank(1)

- Tire Protection Chain(1)

- romani tractor brake(1)

- 5mm eren friction sheet(1)

- 904L hex head bolt machine bolt uns n08904 1.4539 (1)

- Stainless steel 316 special screws knurling custom cold formed fasteners(1)

- Construction Machinery(1)

- 6mm eren friction sheet(1)

- 904L 1.4539 uns n08904 hex tap bolt full thread washers(1)

- Construction Machinery(1)

- Eren 50X50 12mm friction sheet(1)

- 904L heavy hex bolts uns n08904 stainless steel bolt China(1)

- Tire Protection Chain(1)

- Excavator Friction Disc(1)

- Compressors

- Liquid Containers

- Fans & Turbomachinery

- Safety Services

- Electric Services

- Commercial & Trading services

- PVC and UPVC Pipe(2)

- Brick(1)

- Counter(1)

- Rebar(1)

- Escalator(1)

- Kitchen Hood(1)

- Butterfly Valve with Flange(1)

- Carbon steel Pipe(1)

- Flange and Ring(1)

- polyethylene fittings(1)

- Stud Bolt(1)

- P.C Wire & P.C Strand(1)

- Chain Sling(1)

- selling(1)

- ПВХ и ПВХ трубы(1)

- ПВХ и UPVC push fit(1)

- Granite tile(1)

- Cement Type 1 and 2(1)

- Cooling Tower(1)

- Profile(1)

- Security Doors (1)

- Gate Valve(1)

- Ball Valve(1)

- Stainless Steel Pipe(1)

- Carbon Steel Flange (1)

- Stainless Steel Flange(1)

- Hex Nut(1)

- Chain(1)

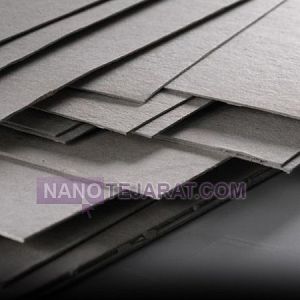

- Steel Sheet(1)

- Meat products(1)

- Двутавровая балка(1)

- противоугонная дверь(1)

- Drywall Gypsum Panel(1)

- Push Fit and Pipe Connections(1)

- Manhole Cover(1)

- Elevator Cabin(1)

- Shower Box(1)

- Check Valve(1)

- Safety Valve(1)

- Polyethylene pipe PE80, PE100(1)

- polyethylene Flange(1)

- Elbow (1)

- Spring Washer Split Washer(1)

- Wire rope Sling(1)

- Steel Wire(1)

- Гипсокартонная панель гипсокартона(1)

- таз(1)

- Кухонная мойка(1)

- Sandwich Panel(1)

- Steel Pipe and Connections(1)

- I-Beam(1)

- Elevator Panels(1)

- Kitchen Sink(1)

- Butterfly Valve without Flange(1)

- Polyethylene pipe (1)

- Galvanized Steel pipe(1)

- Steel Pipe fittings(1)

- Hexagon Bolt(1)

- bolt and nut(1)

- Rigging hardware(1)

- FC steel wire rope (1)

- Сэндвич-панель(1)

- шкаф для воды(1)

- Кухонный шкаф(1)

- Packing & Printing Services

- Agriculture Services

- Construction Services

- Poultry Equipment

- Agriculture Services

- Cattle & Poultry Drugs

- Fertilizer & Pesticide

- Agriculture & Farming Machinery

- Glue

- Rubber and Plastic

- Chemical Lab Tools

- Machinery

- Silicon & Carbon

- Iron

- Mining Machine

- Fixed Jaw Plate/Swing Jaw Plate/Jaw Crusher Spare Parts/Mn13cr2 Jaw Plate/Jaw Plate(1)

- Rock Impact Crusher/Impact Crushing Machine/Impact Crusher(1)

- Impact Crusher Blow Bar/Crusher Blow Bar/Blow Bar(1)

- Spare parts and accessories sand(1)

- Cone Crusher Concave/Cone Crusher Swing Cone/Swing Cone/Concave(1)

- Production and supply of crusher parts sand(1)

- Impact Crusher Liner Plate/Crusher Lining Board/Liner Plate(1)

- Blades, corners, nails and pickaxes construction machinery(1)

- Accurate scales

- Drilling Machine

- Pipe, Fitting and Valve

- Antenna

- Phone, Fax and parts

- Transceiver

- Tower crane & Lift truck

- Valves

- Expansion joint(1)

- Polyethylene reducer 75x63(1)

- Polyethylene Tee 50x50x50(1)

- Farab electric and manual diaphragm control valve model DLG16(1)

- Poliran polyethylene inspection tee(1)

- Male Threaded Polyethylene Connector Size 20x1-2(1)

- 25mm Polyethylene End Cap(1)

- Kitz Butterfly Valve(1)

- Threaded Male Polyethylene Connector Size 50x1 1-4(1)

- 63mm Polyethylene End Cap(1)

- Ball valve with Nojix actuator(1)

- 90x3 mm Male Threaded Polyethylene Compression Fitting(1)

- 90 mm polyethylene end cap(1)

- Wafer Check Valve(1)

- Sewage Equipment

- Concrete Pump

- Housing Equipment

- Isolation

- Hoist

- kato 5 ton electric hoist(1)

- electric hoist(1)

- Demag Used Hoist(1)

- Stock electrick hoist(1)

- 400 kg electric winch(1)

- Crosby American lifting chain(1)

- 3 phase electric hoist(1)

- KITO Electric Hoist(1)

- Kito electric Hoist(1)

- Second hand electric hoist(1)

- electric hoist chain(1)

- CROSBY G120 hoist chain(1)

- Harrington Electric Hoist(1)

- Electric hoist(1)

- Elephant electric hoist(1)

- kato 3 ton electric hoist(1)

- used hoist(1)

- DEMAG electric hoist(1)

- WKTO electric hoist(1)

- Metal Accessories

- Nano Materials

- Refurbishment

- Parquet

- Booth Making

- Spatial Design

- Ceramics and Composites

- Cutting and shaping tools

- SOLID CARBIDE BALL NOSE END MILLS 8(9)

- -(4)

- -(3)

- SOLID CARBIDE END MILLS 6(3)

- -(2)

- SOLID CARBIDE BALL NOSE END MILLS 2(2)

- SOLID CARBIDE END MILLS 1(2)

- -(2)

- SOLID CARBIDE END MILLS 12(1)

- SOLID CARBIDE END MILLS 20(1)

- SOLID CARBIDE END MILLS 4(1)

- SOLID CARBIDE END MILLS 10(1)

- SOLID CARBIDE END MILLS 18(1)

- SOLID CARBIDE END MILLS 3(1)

- SOLID CARBIDE END MILLS 8(1)

- SOLID CARBIDE END MILLS 16(1)

- SOLID CARBIDE END MILLS 2(1)

- SOLID CARBIDE END MILLS 6(1)

- SOLID CARBIDE END MILLS 14(1)

- SOLID CARBIDE BALL NOSE END MILLS 1(1)

- SOLID CARBIDE BALL NOSE END MILLS 5(1)

- SOLID CARBIDE BALL NOSE END MILLS 12(1)

- SOLID CARBIDE BALL NOSE END MILLS 20(1)

- zcc ct(1)

- -(1)

- -(1)

- -(1)

- -(1)

- electerod(1)

- PERMANENT-ELECTRO MAGNETIC CHUCK(1)

- 3JAW SCROLL CHUCKS D1 CAMLOCK DIRECT MOUNTING (1)

- CNC MILLING MACHINE(1)

- CNC MILLING MACHINE(1)

- CNC MACHINE CENTER(1)

- CNC MACHINE CENTER(1)

- PRECISION COMPACT MC VISE(1)

- -(1)

- SOLID CARBIDE END MILLS 1(1)

- SOLID CARBIDE END MILLS 5(1)

- SOLID CARBIDE END MILLS 6(1)

- SOLID CARBIDE END MILLS 14(1)

- SOLID CARBIDE END MILLS 1(1)

- SOLID CARBIDE END MILLS 6(1)

- SOLID CARBIDE END MILLS 12(1)

- SOLID CARBIDE END MILLS 20(1)

- SOLID CARBIDE END MILLS 4(1)

- SOLID CARBIDE END MILLS 10(1)

- SOLID CARBIDE END MILLS 18(1)

- SOLID CARBIDE END MILLS 3(1)

- SOLID CARBIDE END MILLS 8(1)

- SOLID CARBIDE END MILLS 16(1)

- SOLID CARBIDE BALL NOSE END MILLS 6(1)

- SOLID CARBIDE BALL NOSE END MILLS 14(1)

- FRA HAND TAPS M10(1)

- -(1)

- -(1)

- protractors(1)

- -(1)

- مته 5 شیار(1)

- Impact rim wrench(1)

- PERMANENT-ELECTRO MAGNETIC CHUCK(1)

- 3JAW SCROLL CHUCKS D1 CAMLOCK DIRECT MOUNTING (1)

- CNC MILLING MACHINE(1)

- CNC MACHINE CENTER(1)

- CNC MACHINE CENTER(1)

- PRECISION COMPACT MC VISE(1)

- PRECISION COMPACT MC VISE(1)

- -(1)

- -(1)

- SOLID CARBIDE END MILLS 2(1)

- SOLID CARBIDE END MILLS 8(1)

- SOLID CARBIDE END MILLS 16(1)

- SOLID CARBIDE END MILLS 2(1)

- SOLID CARBIDE END MILLS 5(1)

- SOLID CARBIDE END MILLS 14(1)

- SOLID CARBIDE END MILLS 5(1)

- SOLID CARBIDE END MILLS 14(1)

- SOLID CARBIDE END MILLS 20(1)

- SOLID CARBIDE END MILLS 4(1)

- SOLID CARBIDE END MILLS 10(1)

- SOLID CARBIDE END MILLS 18(1)

- SOLID CARBIDE BALL NOSE END MILLS 3(1)

- SOLID CARBIDE BALL NOSE END MILLS 16(1)

- SOLID CARBIDE END MILLS(1)

- Measuring and machining tools(1)

- -(1)

- -(1)

- digital protractor(1)

- پیچ گوشتی برقی با تغذیه خودکار فاین مدل SCT 5-40 M(1)

- tct hole sawe(1)

- CHIP COLLECTOR MINI HANDY TYPE(1)

- ELECTRONIC TOOL LENGTH SETTER(1)

- CNC MILLING MACHINE(1)

- CNC MACHINE CENTER(1)

- CNC MACHINE CENTER(1)

- PRECISION COMPACT MC VISE(1)

- SOLID CARBIDE END MILLS 3(1)

- SOLID CARBIDE END MILLS 10(1)

- SOLID CARBIDE END MILLS 18(1)

- SOLID CARBIDE END MILLS 3(1)

- SOLID CARBIDE END MILLS 8(1)

- SOLID CARBIDE END MILLS 16(1)

- SOLID CARBIDE END MILLS 2(1)

- SOLID CARBIDE END MILLS 14(1)

- SOLID CARBIDE END MILLS 1(1)

- SOLID CARBIDE END MILLS 5(1)

- SOLID CARBIDE END MILLS 12(1)

- SOLID CARBIDE END MILLS 20(1)

- SOLID CARBIDE BALL NOSE END MILLS 4(1)

- SOLID CARBIDE BALL NOSE END MILLS 10(1)

- SOLID CARBIDE BALL NOSE END MILLS 18(1)

- -(1)

- vps302(1)

- -(1)

- digital protractor(1)

- -(1)

- Vertex protractor(1)

- CROSS TABLE(1)

- ELECTRONIC TOOL LENGTH SETTER(1)

- CNC MILLING MACHINE(1)

- CNC MACHINE CENTER(1)

- CNC MACHINE CENTER(1)

- PRECISION COMPACT MC VISE(1)

- -(1)

- -(1)

- SOLID CARBIDE END MILLS 4(1)

- Sewing and weaving tools

- Measuring equipment

- endmill(33)

- endmill Carbide(15)

- drill carbide(7)

- end mill single 1 flute(7)

- endmill Carbide(2)

- drill carbide(2)

- endmill Carbide(1)

- endmill Carbide(1)

- drill carbide(1)

- drill carbide(1)

- drill carbide(1)

- drill carbide(1)

- drill carbide(1)

- drill carbide(1)

- Digital protractor(1)

- dIGITAL PROTRACTORS LEVEL TYPE(1)

- dIGITAL PROTRACTORS LEVEL TYPE(1)

- DEGREE PROTRACTOR(1)

- RAPID ACTION VICES(1)

- Electrode(1)

- endmill Carbide(1)

- endmill Carbide(1)

- endmill Carbide(1)

- endmill Carbide(1)

- endmill Carbide(1)

- endmill Carbide(1)

- drill carbide(1)

- drill carbide(1)

- drill carbide(1)

- drill carbide(1)

- drill carbide(1)

- drill carbide(1)

- drill carbide(1)

- protractors(1)

- dIGITAL PROTRACTORS LEVEL TYPE(1)

- dIGITAL PROTRACTORS LEVEL TYPE(1)

- dIGITAL PROTRACTORS LEVEL TYPE(1)

- DIGITAL DEGREE PROTRACTOR(1)

- digital protractor - level type(1)

- endmill Carbide(1)

- endmill Carbide(1)

- endmill Carbide(1)

- endmill Carbide(1)

- drill carbide(1)

- drill carbide(1)

- drill carbide(1)

- drill carbide(1)

- drill carbide(1)

- drill carbide(1)

- drill carbide(1)

- Universal bever protractors(1)

- dIGITAL PROTRACTORS LEVEL TYPE(1)

- dIGITAL PROTRACTORS LEVEL TYPE(1)

- dIGITAL PROTRACTORS LEVEL TYPE(1)

- LIGHTED INSPECTION MIRROR(1)

- digital protractor -level type (1)

- endmill Carbide(1)

- endmill Carbide(1)

- endmill Carbide(1)

- endmill Carbide(1)

- endmill Carbide(1)

- drill carbide(1)

- drill carbide(1)

- drill carbide(1)

- drill carbide(1)

- drill carbide(1)

- drill carbide(1)

- Dial protractor(1)

- dIGITAL PROTRACTORS LEVEL TYPE(1)

- dIGITAL PROTRACTORS LEVEL TYPE(1)

- DEGREE PROTRACTOR(1)

- ELECTRONIC T GAUGEHEIGHT OFFSE(1)

- endmill Carbide(1)

- endmill Carbide(1)

- endmill Carbide(1)

- Gearbox

- Marelli Marine Electric Motor Italy(1)

- Siemens three-phase brake motor(1)

- Siemens two-speed electric motor(1)

- WEG three-phase electric motor(1)

- SEW Germany direct shaft gearbox(1)

- 9RX John Deere Tractor graphite plate(1)

- Suger factory acid pump(1)

- Hoist electric motor(1)

- Cemp Explosion-Proof Electric Motor(1)

- ABB Dual-Speed Electric Motor(1)

- LEROY SOMER Dual-Speed Electric Motor(1)

- VEM Marine Electric Motor(1)

- Kaijieli Brake Electric Motor(1)

- WEG USA Two-Speed Electric Motor(1)

- Siemens Three-Phase Electric Motor(1)

- Yilmaz direct shaft gearbox (1)

- Alto friction plate for dana spicer(1)

- 3 phase AC electric motor(1)

- Bonfiglioli direct shaft gearbox(1)

- RAEL Explosion Proof Electric Motor(1)

- AEG two-speed electric motor from Germany(1)

- Siemens Marine Electric Motor(1)

- Two-speed three-phase Motogen electric motor(1)

- Electrogen Two-Speed Electric Motor(1)

- Motogener three-phase electric motor(1)

- Bonfiglioli Italy direct shaft gearbox(1)

- SEW RF Series Direct Shaft Gearbox with Flange and Vertical Mounting(1)

- single phase AC electric motor(1)

- Siemens explosion-proof electric motor(1)

- Siemens dual-speed electric motor(1)

- ABB Marine Electric Motor(1)

- WEG Marine Electric Motor from Brazil(1)

- ABB two-speed electric moto(1)

- ABB Three-Phase Electric Motor(1)

- VEM three-phase electric motor(1)

- Motovario Italy direct shaft gearbox(1)

- Rossi H Series helical gearbox, manufactured in Italy(1)

- Flange single phase electric motor(1)

- ABB explosion-proof electric motor(1)

- VEM Two-Speed Electric Motor(1)

- Bearing and belt

- Peugeot 405 car refractory bearing(1)

- -(1)

- -(1)

- SKF angular contact bearing roller(1)

- Peugeot 206 car refractory bearing(1)

- Pride car refractory bearing(1)

- -(1)

- pillow block bearing(1)

- NTN angular contact bearing roller(1)

- Automotive refractory bearing L90(1)

- -(1)

- pillo block bearing(1)

- KOYO angular contact bearing roller(1)

- Samand car refractory bearing(1)

- Angular contact ball bearing(1)

- NACHI angular contact ball bearing(1)

- NSK angular contact bearing roller(1)

CT

| lentmarket |

| Iran |

| 09122003350 |

5mm eren friction sheet

The EREN industrial sheet brake lining 50X50 mm with 5 mm thickness from Turkey is manufactured from high-strength aramid fibers, phenolic resin, and friction modifiers. Its tensile strength reaches 42–46 MPa, providing durability under repeated mechanical loads. Thermal resistance allows operation up to 320°C without significant degradation, while wear resistance under ISO 6310 standard testing remains below 0.12 mm per 1000 cycles. The engineered fiber matrix ensures uniform pressure distribution, reducing localized wear, vibration, and thermal hotspots. Friction coefficients are stable between 0.36 and 0.43 in dry conditions and 0.31 to 0.38 under lubricated conditions. Weight per square meter is approximately 1.1 kg, supporting ease of installation in industrial braking systems. High production precision maintains a thickness tolerance of ±0.1 mm, guaranteeing consistent performance and reducing vibration or noise during operation. The combination of lightweight design, thermal stability, and abrasion resistance makes it suitable for industrial machinery and commercial vehicles.

This EREN sheet lining exhibits strong chemical resistance against oils, water, and moderate corrosive agents, maintaining structural integrity and consistent friction. Compressive resilience a

| |

| lentmarket | 09122003350 |

| Tarom-boxel |

| Iran |

| 02155429480 |

ELEPHANT electric hoist

ELEPHANT is a leading Japanese manufacturer of overhead electric cranes with decades of experience in industrial equipment design and production. Its products are renowned for high build quality, precise operation, and long service life. ELEPHANT uses premium raw materials and advanced Japanese technology for motors, lifting systems, and chains or wire ropes. Compliance with international standards EN 14492 and FEM ensures the safety and high performance of all ELEPHANT cranes.

ELEPHANT overhead cranes are available in capacities ranging from 0.5 to 20 tons, including single-girder, double-girder, chain-driven, and wire-rope models. Each model is engineered for specific industrial applications, offering different lifting speeds, span lengths, and motor types. Dual-speed and four-function systems in some models allow precise and rapid load handling. This variety enables users to select the most suitable crane based on the requirements of their workshop or production line.

The trolley and horizontal movement system of ELEPHANT cranes are made from high-strength steel with quality bearings, ensuring smooth and vibration-free load travel. The modern, robust trolley design maintains load stability throughout the movement path. Electromagnetic brakes and overload limiters provide

| |

| Tarom-boxel | 02155429480 |

| lentmarket |

| Iran |

| 09122003350 |

6mm eren friction sheet

The EREN non-asbestos industrial sheet brake lining from Turkey, size 50X50 mm with 6 mm thickness, is manufactured from high-strength aramid fibers, phenolic resin, and friction-enhancing additives. Its tensile strength ranges from 43 to 47 MPa, providing durability under repeated mechanical loads. Thermal resistance allows operation up to 320°C without significant degradation. Wear resistance under ISO 6310 standard testing remains below 0.11 mm per 1000 cycles, ensuring long service life. The woven fiber matrix distributes pressure evenly, reducing localized wear, vibration, and thermal hotspots. Friction coefficients are stable between 0.37 and 0.44 in dry conditions and 0.32 to 0.39 under lubricated conditions. Unit weight per square meter is approximately 1.15 kg, supporting easy installation in industrial braking systems. High production precision maintains a thickness tolerance of ±0.1 mm for consistent, vibration-free performance.

The EREN sheet lining production process ensures uniform resin and additive distribution, providing consistent and homogeneous performance across all sheets. Compressive resilience averages 8%, allowing the material to recover its shape after repeated mechanical stress. The lining demonstrates strong chemical resistance against oils, water

| |

| lentmarket | 09122003350 |

| Baygan-Sanat |

| Iran |

| 09196218230 |

ABB Marine Electric Motor

The ABB marine electric motor is designed with a rated power range from 0.75 kW to 1000 kW, making it ideal for heavy-duty marine applications such as ship propulsion systems, seawater pumps, and offshore cargo handling equipment. The three-phase ABB marine motor typically operates at voltages between 400 and 690 volts and supports frequencies of 50 or 60 Hz. It is available in high-efficiency classes IE3 and IE4, significantly reducing energy consumption during continuous operation. With thermal class F or H, cooling systems like IC411 or IC416, and perfectly balanced rotor and stator assemblies, these motors minimize vibration and extend operational life even under harsh marine conditions. The use of grease-lubricated bearings capable of handling both radial and axial loads makes them highly suitable for ambient temperatures up to 55°C and high relative humidity.

The ABB marine motor housing is made from ductile cast iron or marine-grade aluminum with an industrial epoxy coating, offering excellent resistance to corrosion from saltwater and marine atmospheres. Protection ratings ranging from IP56 to IP66 ensure safe and reliable performance against water ingress and airborne particles. These motors are engineered in compliance with international standards such as IEC 60034,

| |

| Baygan-Sanat | 09196218230 |

| lentmarket |

| Iran |

| 09122003350 |

Eren 50X50 12mm friction sheet

The industrial brake lining sheet EREN Turkey model 50X50 with a 12 mm thickness is manufactured from non-asbestos composite materials with an average density of 2.00 g/cm³. Its chemical composition includes approximately 30% aramid and cellulose fibers, 25% phenolic resin, 25% metallic powders mainly bronze and copper, and 20% heat-resistant mineral fillers. This formulation provides a stable structure with a consistent friction coefficient ranging from 0.40 to 0.47. EREN brake linings are designed for industrial braking systems, heavy cranes, and process machinery that require smooth engagement and high mechanical stress resistance.

The production process of the EREN sheet is precisely controlled with a dimensional tolerance of ±0.1 mm. Each sheet undergoes compression strength, porosity, and surface uniformity testing prior to packaging. The product complies with international standards ISO 26865, SAE J661, and DIN 6951, ensuring stable frictional performance across varying mechanical and thermal conditions. Tight thickness tolerance and uniform layer bonding significantly enhance the material’s durability and adhesion.

In terms of wear performance, the 12 mm EREN lining demonstrates a wear rate of approximately 0.16 mm³/N·m and achieves over 1700 operating hours w

| |

| lentmarket | 09122003350 |

| omid-lift |

| Iran |

| 021-55414164 |

2 ton chain electric hoist with trolley

The 2-ton electric chain hoist with motorized trolley, 4-function type lifting up, lowering down, forward travel, and backward travel is manufactured in China and designed for medium-duty industrial applications. The unit is equipped with a high-efficiency three-phase induction motor, typically operating at 380V/50Hz, with a thermal protection system to prevent overheating. Its lifting speed is generally in the range of 6–8 m/min, while the traveling trolley moves horizontally at approximately 10–20 m/min, depending on the model. The gearbox is constructed with hardened alloy steel gears for improved durability, and the load chain is made of Grade 80 alloy steel to ensure maximum tensile strength. Safety features include an electromagnetic brake, upper and lower limit switches, and overload protection for reliable operation.

This type of hoist is widely used in factories, assembly lines, metal workshops, construction warehouses, and maintenance facilities where safe and efficient material handling is required. Its 4-function capability allows both vertical and horizontal load movement, making it ideal for overhead beam systems and production halls with limited space. The motorized trolley enables precise positioning of heavy components up to 2,000 kg, reducing manual handl

| |

| omid-lift | 021-55414164 |

| Baygan-Sanat |

| Iran |

| 09196218230 |

Marelli Marine Electric Motor Italy

The Marelli marine electric motor, manufactured in Italy, is one of the most advanced electric motors in the maritime industry, designed and produced using cutting-edge European technology. These motors typically come in power ranges from 0.5 to 50 kilowatts and operate at voltages between 380 to 480 volts in three-phase configurations, fully reinforced for use in harsh marine and saline environments. International standards such as IEC 60034 and IP65/IP66 are strictly adhered to, ensuring complete protection against water ingress and dust. High energy efficiency, a power factor above 0.95, and continuous duty rating S1 are key features of these marine electric motors, resulting in reduced energy consumption and extended motor lifespan.

Mechanically, Marelli motors are equipped with squirrel-cage rotors designed to minimize vibration and noise, capable of withstanding high mechanical and thermal shocks. The cooling system is available in air-cooled IC411 or water-cooled ICW versions, customizable per customer requirements to maintain optimal performance even in high-temperature marine environments. Additionally, the motors can be installed in various orientations and utilize high-quality bearings to increase shaft durability and reduce wear. These characteristics make Marelli

| |

| Baygan-Sanat | 09196218230 |

| hydraulicmarket |

| Iran |

| 021-55130771 |

Ferguson tractor hydraulic pump repair

Repairing the hydraulic pump of a Massey Ferguson 285 tractor is a highly specialized process that requires mechanical knowledge and precise tools. The pump is responsible for transmitting hydraulic oil pressure to the system, and any malfunction can reduce the efficiency of lifting arms and agricultural implements. Common failure symptoms include oil leakage, sudden pressure loss, and unusual noise during operation. Identifying these signs early and performing timely repairs prevents further damage to other hydraulic components.

During the repair of the Massey Ferguson 285 hydraulic pump, the internal parts such as gears, O-rings, and valves must be carefully inspected. Cleaning the components from oil residues and metallic deposits is essential, as contamination can cause wear and shorten the pump’s service life. Using high quality hydraulic oil that complies with the specifications of the Massey Ferguson tractor ensures reliable performance, especially under demanding working conditions.

After replacing or repairing the worn components of the Massey Ferguson 285 hydraulic pump, the system must be properly bled. Air bleeding prevents the formation of bubbles in the hydraulic circuit, ensuring smooth cylinder operation. A final performance test, including measuring the o

| |

| hydraulicmarket | 021-55130771 |

| Baygan-Sanat |

| Iran |

| 09196218230 |

ABB two-speed electric moto

The ABB two-speed electric motor, manufactured in Sweden with advanced technology and international standards, is an ideal choice for industrial applications requiring precise speed control. These dual-speed motors, with power ratings ranging from 0.75 to 30 kilowatts, operate at speeds of 1500 and 3000 RPM. The design of the ABB two-speed motor complies with the IE3 energy efficiency class, helping to reduce power consumption and increase efficiency in industrial projects. The motor housing is made of cast iron or aluminum and is protected against dust and moisture with an IP55 rating. Class F insulated windings ensure long-term operation at high temperatures. These features make the ABB motor suitable for industrial machinery and pumping systems with variable speed requirements.

Other technical specifications of the ABB two-speed electric motor include the IC411 cooling system, which uses an external fan to optimize operating temperature and extend motor lifespan. Its high starting torque allows it to handle heavy loads across various industries, including production lines, material handling equipment, and pumps. The motor operates on three-phase voltages ranging from 220 to 690 volts, facilitating easy installation in different industrial power networks. With its quiet desi

| |

| Baygan-Sanat | 09196218230 |

| Baygan-Sanat |

| Iran |

| 09196218230 |

Rossi H Series helical gearbox, manufactured in Italy

The Rossi H Series helical gearbox, manufactured in Italy, is a highly efficient industrial transmission system designed for continuous and precise power transfer in heavy-duty machinery. It features a multi-stage helical gear arrangement with case-hardened and ground gears manufactured to DIN class 6 precision. The output torque reaches up to approximately 18,000 Nm, with mechanical efficiency exceeding 97 percent. The reduction ratio ranges from 3.5 to 400, and its modular design allows flexible installation in foot-mounted or flange-mounted configurations. The housing is made of G300 ductile cast iron with precision machining to minimize vibration and noise. The lubrication system can be splash or forced circulation, depending on load and speed requirements.

The Rossi H Series gearbox incorporates high-load-capacity rolling bearings and heat-resistant seals for long service life. The input and output shafts are coaxial and dynamically balanced for loss-free torque transmission. The operational temperature range is from -25 to +90 degrees Celsius, and the gearbox can be directly coupled with IEC electric motors up to 132 kW. The nominal noise level remains below 70 dB, and the unit weight varies between 150 and 720 kilograms depending on the model. Certified under CE and ISO

| |

| Baygan-Sanat | 09196218230 |

| SSP |

| Iran |

| 02177607818 |

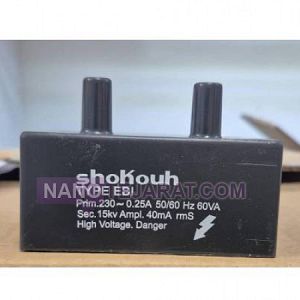

Shokho Electronic EB1 Ignition Transformer

The EB1 ignition transformer from Shokouh Electronic is a reliable component used in gas and oil burner ignition systems, designed to generate a strong and stable spark with an output voltage of approximately 15 kV. With a compact size and durable construction, it is well-suited for use in industrial and semi-industrial environments. Its housing is made from heat- and moisture-resistant materials, and many models feature an IP44 to IP54 protection rating, ensuring safe operation under various environmental conditions. Using this model in well-ventilated areas with controlled humidity significantly contributes to its longevity and consistent performance.

In terms of electrical performance, the EB1 transformer operates on a 220V AC input and is engineered to consume current efficiently, avoiding excess strain on the power system. It functions reliably in ambient temperatures ranging from 0 to 60 degrees Celsius and resists voltage fluctuations. The internal copper winding is insulated with heat-resistant coating, while its output terminals are made from anti-corrosion alloys, ensuring spark stability and reducing the risk of damage. The terminal design allows for fast, safe installation without unintended sparking. These features, along with its high durability and quality build

| |

| SSP | 02177607818 |

| Baygan-Sanat |

| Iran |

| 09196218230 |

Siemens two-speed electric motor

The Siemens two-speed electric motor is an asynchronous squirrel-cage type designed to operate at two different speeds. This motor is available in a wide range of power ratings, from a few kilowatts up to several hundred kilowatts, with a rated voltage between 380 and 690 volts. The first speed typically runs around 1500 RPM, while the second speed reaches approximately 3000 RPM, adjustable depending on the winding configuration. High efficiency, thermal insulation class F, and IP55 protection are key features of this industrial motor, ensuring durability and stable performance under harsh working conditions. Siemens’ advanced design reduces noise and vibration, significantly extending the lifespan of moving components.

In the design of the Siemens two-speed motor, the use of high-quality iron cores and standard-thickness copper windings facilitates efficient electrical-to-mechanical energy conversion with minimal losses. These two-speed Siemens motors enable precise speed control for industrial applications such as pumps, fans, and compressors. Compatible with standard frequencies of 50 or 60 Hz, they can withstand high momentary loads. Additionally, speed control via soft starters and variable frequency drives is easily achievable. Utilizing these motors in two-speed systems

| |

| Baygan-Sanat | 09196218230 |

| Roll-pars-belt-bearing |

| Iran |

| 09126482568 |

Samand car refractory bearing

The heat-resistant bearing for the Samand vehicle is a key component in the suspension and wheel systems, designed with advanced manufacturing technology and high-quality materials to ensure stable and long-lasting performance. Featuring precise engineering and a sealing system resistant to heat, moisture, and contaminants, it effectively prevents the intrusion of dust and liquids into the internal mechanism. This results in an extended service life and reduced maintenance needs. Commonly installed in the front or rear wheels of the Samand, the bearing offers excellent radial and axial load capacity, ensuring reliable operation in both urban and long-distance driving conditions.

From a technical standpoint, the heat-resistant bearing designed for the Samand meets the factory-standard inner and outer diameters required for proper wheel fitment. It is typically manufactured from hardened alloy steel with an anti-corrosion coating, and its internal lubrication consists of a high-temperature grease capable of withstanding up to approximately 200°C. These features, combined with a dual sealing structure, provide exceptional resistance to mechanical stress, wear, and high temperatures. Using a high-quality heat-resistant bearing in a Samand vehicle not only enhances safety but also

| |

| Roll-pars-belt-bearing | 09126482568 |

| takinboksel |

| Iran |

| 021-55422784 |

TOYO 3 ton electric hoist

The 3-ton TOYO electric hoist, single speed, two-function, hook type without trolley, has a nominal lifting capacity of 3000 kg and operates with a 380 V three-phase power supply. It is equipped with an electric motor rated around 3.5 to 4 kW, delivering a lifting speed of approximately 8 meters per minute in single-speed mode. The wire rope diameter is typically 10 to 12 mm, and the standard lifting height ranges from 6 to 12 meters. The forged steel hook with a safety latch ensures secure load handling.

The 3-ton TOYO electric hoist is widely used in industrial workshops, construction projects, and heavy metal industries where high-capacity lifting is required. Since it comes without a trolley, it is designed for fixed installation or use on stationary structures, making it suitable for confined spaces. Its single-speed configuration simplifies operation and reduces maintenance costs compared to dual-speed models.

The safety factor of the 3-ton TOYO hoist is generally rated between 1.25 and 1.5 times the nominal capacity, in compliance with EN 14492 and FEM standards. This means the unit can withstand test loads up to 3750–4500 kg. An electromagnetic braking system, overload protection, and motor thermal cut-off provide enhanced safety. These features make the hoist rel

| |

| takinboksel | 021-55422784 |

| Roll-pars-belt-bearing |

| Iran |

| 09126482568 |

Peugeot 405 car refractory bearing

The heat-resistant bearing for the Peugeot 405 is a critical component in the vehicle’s suspension and wheel system, playing a vital role in maintaining stability, balance, and reducing friction between moving parts. This bearing is designed using advanced manufacturing technologies and high-performance materials that can withstand heat and pressure, ensuring reliable operation under various driving conditions, including high-speed travel, rough roads, and extreme temperature changes. Its advanced sealing system prevents the intrusion of dust, water, and contaminants into the internal mechanism, effectively protecting against premature wear and performance degradation.

Technically, the heat-resistant bearing for the Peugeot 405 is manufactured to meet the vehicle’s factory-standard dimensions and is made from hardened alloy steel with an anti-corrosion coating to resist rust and oxidation. It is internally lubricated with high-temperature industrial grease capable of withstanding up to 200°C, enabling smooth and uninterrupted performance under high thermal and mechanical stress. The durable construction, precision-engineered ball elements, and optimized design help extend the component’s lifespan while also reducing wheel noise, improving driving comfort, and contributi

| |

| Roll-pars-belt-bearing | 09126482568 |

| SSP |

| Iran |

| 02177607818 |

Shokho Electronics photocell model UVZ780 red

The Shokho Electronics photocell model UVZ780 red is a widely used component in flame detection systems for gas and diesel heating systems, designed with precision and a durable housing. This sensor operates using ultraviolet UV flame detection technology and reacts with high sensitivity to the presence or absence of flame in the combustion chamber. Its red-colored body is made of heat- and corrosion-resistant materials, ensuring reliable performance under harsh environmental and thermal conditions. The photocell works alongside the burner control unit and plays a critical role in ensuring operational safety and flame stability.

Structurally, the UVZ780 model features a simple yet highly effective design, allowing for easy installation on a wide range of burners. Its operating voltage range is engineered for full compatibility with most flame control systems, while offering good resistance against electrical fluctuations. The sensor functions by generating a voltage in response to flame radiation, which is then amplified and used to trigger the burner controllers relay. The Shokho Electronics photocell model UVZ780 red is a cost-effective option for light industrial and semi-industrial applications, delivering reliable performance in terms of both accuracy and service life.

| |

| SSP | 02177607818 |

| sayalsanat |

| Iran |

| 021-22087856 |

Farab electric and manual diaphragm control valve model DLG16

The Farab electric and manual diaphragm control valve model DLG16 is designed for precise flow regulation in water, steam, oil, and industrial fluid pipelines. The body is made of ductile iron GGG40 with a nominal pressure rating of PN16, and the diaphragm is EPDM or NBR for temperature and pressure resistance. The stainless steel stem and seat ensure reliable sealing, while the diaphragm mechanism provides leak-free operation under variable pressures. The valve features an electric actuator with position control and an emergency manual override. Flanged ends comply with EN 1092-2, and installation dimensions follow DIN 3202. Operating temperature ranges from 0–120°C, and the valve is rated for up to 16 bar.

The Farab DLG16 diaphragm valve provides flexible and precise flow control with minimal pressure drop. The electric actuator is equipped with position sensors and electronic control for accurate diaphragm positioning. The diaphragm is replaceable and designed for long-term operation under harsh industrial conditions. The body design allows easy access for maintenance and diaphragm replacement. Each valve undergoes hydrostatic and leakage testing according to API 598 standards to ensure precise performance, durability, and safe operation in industrial systems.

| |

| sayalsanat | 021-22087856 |

| Baygan-Sanat |

| Iran |

| 09196218230 |

Siemens explosion-proof electric motor

ChatGPT said:

The Siemens explosion-proof electric motor is a three-phase induction type with a squirrel cage rotor, available in power ratings from 0.55 to 315 kilowatts. These motors feature an IP66 protection class and thermal class F, making them suitable for environments with flammable gases and explosive dust. They operate within a voltage range of 220 to 690 volts and frequencies of 50 or 60 Hz. The motor housing is made of durable cast iron and fully complies with international standards IEC 60079-0 and IEC 60079-1. Efficiency levels meet IE3 or IE4 standards, and the motors hold ATEX and IECEx certifications.

Siemens explosion-proof motors are offered in temperature classes T4 and T5, capable of continuous operation in ambient temperatures up to 60 degrees Celsius. They utilize IC411 cooling systems and grease-lubricated bearings with high serviceability, enhancing operational lifespan. Dynamically balanced rotors and low vibration reduce noise and improve equipment durability. The terminal box can rotate 90 degrees, facilitating easy installation. These motors can be mounted in IM B3, IM B5, and IM B35 configurations. All components are manufactured with high precision and strict quality control to ensure safe and reliable performance in hazardous environments.

| |

| Baygan-Sanat | 09196218230 |

| blanc-gypsum |

| Iran |

| 021-22087856 |

Gboard impact resistant gypsum panel

The Gboard impact resistant gypsum board features a reinforced core with special fibers that provides an approximate density of 900 to 1050 kilograms per cubic meter. The panel is produced with a thickness of 12.5 millimeters and typical dimensions of 1200 by 2400 millimeters, offering a bending resistance of about 550 to 650 newtons. Its compressed cardboard surface layer absorbs impact energy and enhances structural stability against deformation. The tapered edge design enables precise joint finishing with Knauf compounds. This product can be installed on metal framing systems using CW and UW profiles and is suitable for light to medium lateral loads.

The Gboard impact resistant gypsum panel has a thermal conductivity of approximately 0.25 watts per meter kelvin, providing efficient thermal performance for interior partitions. Sound insulation of the system combined with mineral wool can reach 45 to 52 decibels and reduces transmitted vibrations. The surface resistance of the panel against repeated impacts corresponds to a mechanical hardness exceeding 20 joules. Installation is performed using 25 to 35 millimeter self drilling screws with a maximum stud spacing of 40 centimeters. The product complies with EN 520 types D and F and is suitable for high traffic areas.

| |

| blanc-gypsum | 021-22087856 |

| Roll-pars-belt-bearing |

| Iran |

| 09126482568 |

Peugeot 206 car refractory bearing

The heat-resistant bearing used in the Peugeot 206 is a vital component in the vehicle’s power transmission and rotational systems, specifically designed to perform optimally under high-temperature conditions. Made from high-quality, durable alloys and enhanced with specialized lubricants and coatings, this bearing can withstand extreme heat and heavy mechanical loads. Its application in areas such as wheels, gearboxes, and other rotating systems increases the longevity of parts and reduces overall wear and tear. The sealed structure of the bearing effectively blocks dust and contaminants, ensuring stable and quiet operation across various driving environments.

In terms of design, the heat-resistant bearing for the Peugeot 206 is manufactured with precise and standardized dimensions, allowing for easy installation without any modification to the vehicle’s mechanical system. The rings and balls are made from materials that offer excellent resistance to wear and corrosion, while high-temperature lubricants inside the bearing help minimize friction and extend the component’s service life. These features make the heat-resistant bearing for Peugeot 206 an ideal choice for drivers seeking long-lasting and maintenance-free performance.

| |

| Roll-pars-belt-bearing | 09126482568 |

| shoping-14 |

| Iran |

| 02155433645 |

construction hydraulic pump

The hydraulic pump for construction machinery is designed to generate stable pressure and accurately transfer hydraulic power within the motion systems of heavy equipment. It is an axial piston type featuring a swash plate mechanism with an automatic pressure control system. The displacement range is between 68 and 185 cubic centimeters per revolution, with a rated working pressure up to 340 bar. The housing is made of ductile cast iron GGG45 with a compressive strength of 370 MPa. The inner cylinder surface is reinforced with a 20–25 micron hard chrome layer to minimize wear. It operates reliably between -25°C and +115°C and is built for heavy-duty conditions.

Hydraulic pumps used in construction equipment achieve overall efficiency above 95 percent and utilize optimized flow channels to reduce pressure losses. The input shaft is made of 34CrNiMo6 alloy steel, heat-treated for superior fatigue and torque resistance. The sealing system includes FKM O-rings capable of withstanding high temperatures and pressures up to 400 bar. Tapered roller bearings with a 45 kN radial load capacity ensure mechanical stability and service life exceeding 14,000 hours. These features make the pump an ideal choice for loaders, excavators, and graders.

| |

| shoping-14 | 02155433645 |

| shoping-14 |

| Iran |

| 02155433645 |

Construction machinery engine components

Engine components in construction machinery, including pistons, rings, connecting rod bushings, crankshafts, and hydraulic pumps, are manufactured from alloy steel and high-strength aluminum to withstand cylinder pressures up to 25 MPa and operating temperatures up to 300 degrees Celsius. Dimensions and tolerances are CNC-controlled, with surface finishing precision up to 0.01 millimeters. Contact surfaces are reinforced with wear-resistant coatings, nitriding, and hardening to ensure a service life exceeding 12,000 operating hours. Friction coefficients between contacting surfaces range from 0.08 to 0.12, and components can sustain instantaneous loads up to 2000 Nm.

In the design of construction machinery engine components, oil pathways and cooling channels are optimized to provide uniform lubrication and rapid heat dissipation. Components are engineered to resist vibrations, shocks, and thermal stresses, with thermal deformation under 0.05 millimeters. Weight varies from 0.2 to 35 kilograms depending on function, allowing direct installation on the engine block and chassis with standard bolts and shafts. Reliable operation is ensured within a temperature range of -20 to 300 degrees Celsius, maintaining optimal engine performance.

| |

| shoping-14 | 02155433645 |

| Baygan-Sanat |

| Iran |

| 09196218230 |

RAEL Explosion Proof Electric Motor

The RAEL explosion proof electric motor, manufactured in Italy, is equipped with international ATEX and IECEx certifications, and its protection class ranges from IP55 to IP66. These motors are produced with power ratings from 0.37 to 315 kilowatts and operate at three-phase voltages between 220 and 690 volts. The operating speeds include 750, 1000, 1500, and 3000 revolutions per minute. The RAEL brand explosion-proof motor housing is made of aluminum or cast iron, offering high resistance to impact and corrosion. With insulation classes F and H, the motor guarantees operation in temperatures ranging from -40 to +55 degrees Celsius and features a spark-proof design suitable for explosive environments.

These RAEL explosion proof motors include an IC411 fan cooling system and advanced insulation to protect against moisture and heat. They also support the installation of temperature sensors and encoders for intelligent performance monitoring. Additionally, the anti-vibration system integrated into the RAEL explosion proof motor reduces noise and extends bearing life. With an explosion protection class of Ex d IIB/IIC T4, these motors are considered the ideal choice for the oil, gas, petrochemical, and mining industries.

| |

| Baygan-Sanat | 09196218230 |

| Baygan-Sanat |

| Iran |

| 09196218230 |

Siemens Marine Electric Motor

The Siemens marine electric motor is one of the most advanced and high-quality electric motors designed specifically for use in marine environments and shipbuilding industries.

Technical Specifications of Siemens Marine Electric Motor:

Output power: From a few kilowatts up to several hundred kilowatts depending on model and application needs

Operating voltage: 380V to 690V, three-phase

Frequency: 50/60 Hz

Rotation speed: 750 to 3600 RPM

Insulation class: F or H high heat resistance

Protection rating: IP56 to IP68 full resistance against water and dust

Body material: Aluminum or stainless steel with anti-corrosion coating

Cooling type: IC411 or IC416 external cooling for stable performance

Bearing type: Industrial-grade, durable, and corrosion-resistant bearings

Resistance to moisture and salt: Special protective coatings for marine environments

Compatible with smart motor control systems PLC & VFD

If you are looking to buy a powerful, corrosion-resistant, and highly efficient marine electric motor for your ship, boat, or marine equipment, Siemens electric motors are your best choice.

For pricing information and to purchase Siemens marine electric motors, please contact our experts.

| |

| Baygan-Sanat | 09196218230 |

| Roll-pars-belt-bearing |

| Iran |

| 09126482568 |

Pride car refractory bearing