| sanatariya |

| Iran |

| 02133116613-33961181-3 |

The timing belt is a critical component in power transmission systems responsible for precise synchronization between the crankshaft and camshaft. These belts are typically made from neoprene rubber reinforced with fiberglass or Kevlar fibers. The tensile strength of the belt ranges from 1500 to 3000 Newtons, preventing elongation under load conditions. The belt width varies between 10 and 40 millimeters, with a thickness generally between 4 and 8 millimeters. The belt teeth are designed with a pitch of 8 or 9.525 millimeters to ensure precise engagement with pulleys. ISO 13050 and DIN 7721 standards are commonly applied to control the quality of timing belt manufacturing.

The tooth profile of timing belts can be trapezoidal, curvilinear, or RPP, each optimized for specific operating conditions. Belts are produced in open or endless loop types, commonly ranging from 500 to 1600 millimeters in length. The operating temperature range is defined from -30 to +120 degrees Celsius. In industrial and automotive applications, the belt must operate slip-free with minimal deviation. The expected service life under standard conditions is between 60,000 and 100,000 kilometers or approximately 5,000 hours of operation. Manufacturing quality, uniform thickness, and precise tooth molding s

| |

| sanatariya | 02133116613-33961181-3 |

| power-belt |

| Iran |

| 021-22087856 |

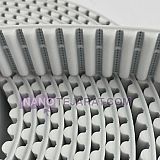

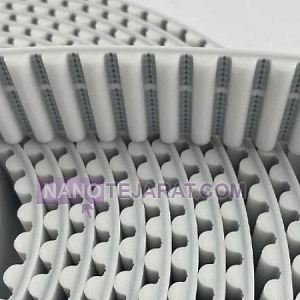

The metric timing belt is manufactured from neoprene rubber or polyurethane reinforced with fiberglass or steel cords to ensure precise and slip-free power transmission. The tooth pitch varies from 2 millimeters to 20 millimeters depending on the standard, while tooth height ranges between 0.8 and 5 millimeters. The tensile strength of these belts is typically in the range of 500 to 3000 newtons per centimeter, enabling use in heavy-duty industrial systems. The operating temperature range of the metric timing belt is between -30 and 100 degrees Celsius, with short-term resistance up to 120 degrees Celsius. High wear resistance, along with oil and moisture tolerance, are also key features of this product.

Other technical specifications include high accuracy in tooth alignment and long-term dimensional stability. The belt width is produced from 6 to 150 millimeters depending on application, and standard rolls are offered in lengths of 50 or 100 meters. The minimum bending radius usually ranges between 20 and 80 millimeters, allowing use with small pulleys. The surface hardness is typically between 80 and 92 Shore A, providing strong resistance against deformation. These belts are designed according to international standards ISO 5296 and DIN 7721, and are widely applied in autom

| |

| power-belt | 021-22087856 |

| yeekta-bearings |

| Iran |

| 021-33925513 |

MEGADYNE industrial timing belts are precision-engineered power transmission components manufactured according to ISO and DIN standards. These belts are typically made from abrasion-resistant polyurethane combined with steel or Kevlar tension cords. Their tensile strength ranges between 2000 and 3500 Newtons and they operate reliably in temperatures from -30 to +100 degrees Celsius. Common tooth pitches in models like RPP or T range from 5 to 14 millimeters. MEGADYNE belts are available in standard widths from 10 to 85 millimeters. High-precision molding of the teeth minimizes noise and vibration in industrial applications.

MEGADYNE’s industrial models such as MEGAflex and MEGApower are designed for high-speed, high-torque, and precision-driven systems. These belts have a service life exceeding 20,000 operating hours under standard conditions. The tooth profiles are curvilinear or parabolic to evenly distribute surface stress and reduce wear. Overall belt thickness typically ranges from 4.5 to 10 millimeters, and open-ended lengths up to 20 meters are available upon request. MEGADYNE industrial timing belts are fully compatible with standard HTD and RPP pulleys. Accurate transmission ratio, precise alignment, and low maintenance make them ideal for automation, packaging, and

| |

| yeekta-bearings | 021-33925513 |

| pishrosanat |

| Iran |

| 09123691065 |

A timing belt is a mechanical component with internal teeth that ensures precise synchronization between the crankshaft and camshaft in internal combustion engines. The belt width varies depending on engine type, typically between 15 and 40 millimeters, with a thickness of about 4 to 8 millimeters. The tooth pitch is usually 8 or 9.525 millimeters, and the number of teeth ranges from 100 to 160. Timing belts are made from rubber reinforced with fiberglass, nylon, or Kevlar. The standard operating temperature range is from -30 to +120 degrees Celsius. The tensile strength of the belt typically ranges from 1500 to 2500 Newtons, offering high resistance to impact stress.

The tooth profile of a timing belt may be trapezoidal or curvilinear, each designed to match specific pulley types. The typical belt length ranges from 800 to 1600 millimeters, with a weight of approximately 200 to 600 grams. International standards such as ISO 9010 and DIN 7721 govern the geometric design and material resistance of timing belts. The belt must operate slip-free and be precisely aligned with pulleys to prevent valve damage. Under normal conditions, the timing belt lifespan is between 60,000 and 100,000 kilometers. In turbocharged or high-RPM engines, this interval should be shortened to minimize t

| |

| pishrosanat | 09123691065 |

| power-belt |

| Iran |

| 021-22087856 |

The Megadyne RPP3 timing belt is manufactured from polychloroprene rubber reinforced with glass fiber cords and coated with nylon fabric, providing excellent tensile strength and abrasion resistance. This belt has a 3-millimeter pitch, and its “Robust Profile” RPP tooth design increases surface contact while minimizing slippage during power transmission. Its tensile strength is measured between 70 and 100 newtons per millimeter of belt width, with a friction coefficient of approximately 0.3. The standard operating temperature range of the Megadyne RPP3 timing belt is from -20 to +100 degrees Celsius, while heat-resistant versions can operate effectively up to 120 degrees.

A key feature of the Megadyne RPP3 timing belt is its high accuracy in synchronization and power transmission with low vibration and reduced noise. It delivers stable performance at speeds up to 9,000 revolutions per minute, with available widths ranging from 9 to 25 millimeters. Standard lengths are produced between 180 and 1500 millimeters, and the curved tooth profile helps reduce stress concentration while extending service life. These specifications make the Megadyne RPP3 timing belt an ideal solution for precision industrial equipment and high-efficiency machinery.

| |

| power-belt | 021-22087856 |

| ebtekarsanat |

| Iran |

| 021-33990391 |

The L timing belt is a common model used in power transmission systems requiring moderate precision, designed for industrial and automotive applications. These belts are typically made of neoprene rubber reinforced with fiberglass fibers, providing tensile strength between 1200 and 2500 Newtons. The tooth pitch of the L timing belt is 9.525 millimeters, and the teeth have a trapezoidal angle designed for smooth operation with standard pulleys of this series. The belt width varies from 6 to 30 millimeters, with an overall thickness of about 5 millimeters. This belt is suitable for transmitting power at moderate speeds within a temperature range of -20 to +90 degrees Celsius.

In the design of the L timing belt, precision tooth molding plays a key role in preventing slippage and increasing belt lifespan. The expected service life of these belts ranges from 3000 to 8000 hours under standard operating conditions. Wear and oil resistance are enhanced using special coatings. The belt’s flexibility allows its use in both open and closed circuits with a minimum bending radius of 30 millimeters. These engineering specifications make the L timing belt an ideal choice for mechanical systems requiring moderate synchronization and low cost.

.jpg?width=160&height=160&cropratio=160:160&image=/admin/uploads/تسمه-تایمینگ-L---ابتکار-صنعت-51-u2231-958211-IMG_20190212_111658 (1).jpg&url=/admin/uploads/تسمه-تایمینگ-L---ابتکار-صنعت-51-u2231-958211-IMG_20190212_111658 (1).jpg)

.jpg?width=300&height=300&cropratio=300:300&image=/admin/uploads/تسمه-تایمینگ-L---ابتکار-صنعت-51-u2231-958211-IMG_20190212_111658 (1).jpg&url=/admin/uploads/تسمه-تایمینگ-L---ابتکار-صنعت-51-u2231-958211-IMG_20190212_111658 (1).jpg) | |

| ebtekarsanat | 021-33990391 |

| power-belt |

| Iran |

| 021-22087856 |

The OPTIBELT DELTA CHAIN Carbon polyurethane timing belt represents one of the most advanced generations of industrial timing belts, offering exceptional performance in power transmission and tensile strength thanks to its multi-layered structure and carbon fiber reinforcement technology. The belt is made of wear-resistant, high-temperature polyurethane and features a carbon core to ensure maximum stability against stretching, deformation, and tearing. Its precisely engineered tooth profile is compatible with standard industrial pulleys, enhancing efficiency and reducing noise in mechanical systems.

A standout feature of this belt is its extremely long service life, even under high loads and at high speeds, making it an ideal choice for industrial machinery, automation systems, packaging equipment, and other precision-driven applications. Additionally, its excellent resistance to oil, chemicals, and UV radiation allows for reliable performance in harsh industrial environments and variable working conditions. The belts maintenance-free operation, easy installation, and reduced overall upkeep costs are further advantages that make the DELTA CHAIN Carbon a highly competitive solution.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The ALPHA Optibelt polyurethane timing belt is an advanced power transmission product designed with cutting-edge technology and high-quality materials. Made from abrasion-resistant polyurethane, it offers excellent resistance to oil, moisture, and high temperatures. Internally, it is reinforced with steel cords or aramid cables that ensure outstanding tensile strength and extended service life. The belt’s teeth are precisely engineered to fully engage with matching pulleys, preventing slippage and ensuring perfect synchronization in motion control systems.

The ALPHA Optibelt polyurethane timing belt is widely used in heavy industrial applications, automated systems, CNC machines, production lines, and packaging industries. These belts offer high strength, optimal flexibility, and excellent resistance to dynamic fatigue, making them ideal for continuous and high-speed operations. Their use reduces maintenance costs and downtime while enhancing operational accuracy, consistent power transmission, and overall system efficiency. Additionally, the belt can be customized in terms of length, width, and tooth profile, making it suitable for a wide range of industrial requirements.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Bando DXL timing belt is manufactured from neoprene rubber reinforced with glass fiber and polyester cords, providing high tensile strength and excellent dimensional stability. The standard pitch of the belt teeth ranges from 2.5 to 10 millimeters, and their surface is coated with nylon fabric to reduce friction and wear. The tensile strength of the belt is in the range of 80 to 110 newtons per millimeter of width, with a friction coefficient measured between 0.28 and 0.32. The operating temperature range is from -25 to +90 degrees Celsius, while heat-resistant models can operate effectively up to 110 degrees.

A key feature of the Bando DXL timing belt is its high precision in power transmission within synchronization systems at medium to high speeds. This belt provides stable operation up to 10,000 revolutions per minute, with available widths ranging from 6 to 40 millimeters. The length options vary from 150 to 1800 millimeters, and the semi-circular tooth design reduces vibration and noise levels to less than 68 decibels. These characteristics make the Bando DXL timing belt an ideal choice for precision industrial equipment and high-accuracy production lines.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

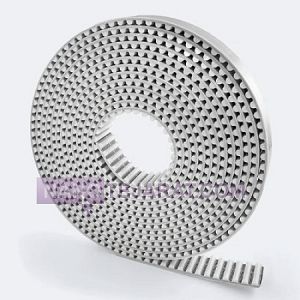

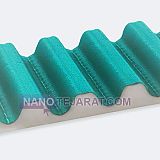

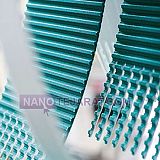

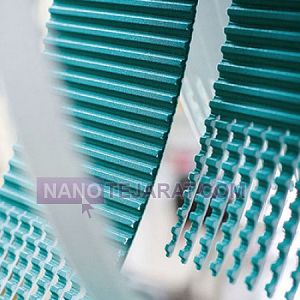

The open circuit timing belt is a key component in power transmission and position control systems used in industrial machinery and automation equipment. Unlike endless belts, it is produced without a loop and typically supplied in rolls or custom-cut lengths. This open design allows users to cut the belt precisely to the required system length. Featuring accurately spaced teeth designed to mesh perfectly with timing pulleys, the belt is commonly made from polyurethane reinforced with Kevlar or steel cords, ensuring high tensile strength, precise motion control, and long-lasting durability.

Open circuit timing belts are widely used in linear motion systems, industrial printers, CNC machines, packaging equipment, and robotic applications. These belts offer excellent resistance to wear, oil, chemicals, and harsh environmental conditions. Their maintenance-free operation and easy installation make them a cost-effective choice. Additionally, the availability of various tooth profiles and the ability to support applications that require precise positioning make the open circuit timing belt a reliable and flexible solution for engineers and industrial designers.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

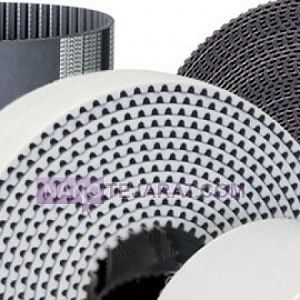

The rubber closed-loop double-sided timing belt is a precise and reliable power transmission component widely used in mechanical systems and industrial automation. Its core structure consists of durable rubber compounds typically neoprene or HNBR reinforced with materials like fiberglass or aramid fibers. The key feature of this belt is the presence of teeth on both sides, allowing it to simultaneously transmit power in two different directions. This dual-sided design significantly enhances performance in systems that require synchronized, bi-directional motion.

The tooth profile is usually trapezoidal or curvilinear, ensuring high engagement accuracy with the pulley and preventing slippage. It is also highly resistant to heat, abrasion, and industrial oils. Since the belt is closed-loop, its length is fixed and usually customized to suit the specific requirements of each system, making accurate selection essential. The double-sided rubber timing belt is an ideal choice for applications such as printing machinery, packaging equipment, and robotic systems where precise and simultaneous power transmission is required in multiple directions.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Megadyne PU welded timing belt T10 PAZ is manufactured from durable thermoplastic polyurethane reinforced with steel or Kevlar cords, providing high tensile strength and long-lasting durability. The belt features a 10 millimeter pitch tooth profile with the PAZ series design, ensuring uniform torque and power transmission in medium-duty industrial systems and precision production lines. Its operating temperature ranges from -20 to +80 degrees Celsius, with excellent resistance to wear, oil, and moisture. Standard belt widths typically range from 16 to 100 millimeters, and thermal welding allows the creation of customized endless loops.

Due to its precise tooth design and high dimensional accuracy, this belt is ideal for packaging machinery, automated assembly lines, and precision power transmission systems. The polyurethane compound with a low friction coefficient reduces energy consumption and improves system efficiency. The broad tooth contact surface ensures uniform force distribution and minimizes vibration at high speeds. Customization in belt length and width provides significant flexibility for specialized industrial applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Megadyne PU welded timing belt RPP14 is manufactured from durable thermoplastic polyurethane reinforced with steel or Kevlar cords, providing high tensile strength and long service life. The belt features a tooth profile with a 14 millimeter pitch, ensuring uniform torque and power transmission in heavy-duty industrial systems and high-load production lines. Its operating temperature ranges from -20 to +100 degrees Celsius, with excellent resistance to wear, oil, and moisture. Standard belt widths typically range from 25 to 115 millimeters, and thermal welding allows production of endless loop belts.

Due to its high dimensional accuracy and precisely engineered tooth design, this belt is ideal for heavy industrial machinery, automated production lines, and precision power transmission systems. The polyurethane compound with a low friction coefficient reduces energy consumption and improves system efficiency. The broad tooth contact surface ensures uniform force distribution and reduces vibration at high speeds. Additionally, customization in belt length and width provides significant flexibility for specialized industrial applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Bando T10 polyurethane timing belt is made from durable polyurethane with a standard hardness of 90 Shore A, designed for power transmission in medium to heavy-duty industrial systems. The belt features teeth spaced 10 millimeters apart, molded to ensure perfect symmetry and exact synchronization on pulleys. Internal cords are made of high-strength fiberglass, maintaining longitudinal stability and enabling the belt to withstand high loads. Belt length, width, and tooth count can be customized for diverse industrial applications, and high precision reduces slippage while improving power transmission efficiency.

This timing belt operates effectively within a temperature range of minus 30 to plus 80 degrees Celsius, maintaining stability across diverse industrial environments. Its polyurethane resistance to oils, ozone, and common chemicals extends operational lifetime. The precise tooth structure and smooth surface reduce friction and minimize noise during operation. It is primarily used in packaging machines, industrial production lines, precision equipment, and textile machinery requiring clean and accurate performance.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Bando T5 polyurethane timing belt is made from durable polyurethane with a standard hardness of 85 Shore A, designed for power transmission in light to medium-duty industrial systems. The belt features teeth spaced 5 millimeters apart, molded to ensure perfect symmetry and exact synchronization on pulleys. Internal cords are made of strong fiberglass, maintaining longitudinal stability and allowing the belt to withstand medium loads. Belt length, width, and tooth count can be customized for diverse industrial applications, and high precision reduces slippage while improving power transmission efficiency.

This timing belt operates effectively within a temperature range of minus 30 to plus 80 degrees Celsius, maintaining stability across diverse industrial environments. Its polyurethane resistance to oils, ozone, and common chemicals extends operational lifetime. The precise tooth structure and smooth surface reduce friction and minimize noise during operation. It is primarily used in packaging machines, precision equipment, industrial production lines, and textile machinery requiring clean and accurate performance.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Megadyne PU welded timing belt TK10 K13 is manufactured from thermoplastic polyurethane reinforced with steel or Kevlar cords, providing high tensile strength and long-lasting wear resistance. The belt features a 10 millimeter pitch tooth profile with the K13 series design, suitable for transmitting medium to high torque in industrial systems and precision production lines. Its operating temperature range is -20 to +80 degrees Celsius, offering excellent resistance to oil, moisture, and abrasion. Belt widths typically range from 20 to 100 millimeters, and thermal welding enables the production of endless loops.

Due to its high dimensional accuracy and engineered TK tooth design, this belt delivers uniform power transmission at high speeds. The combination of polyurethane with a low friction coefficient minimizes energy losses and improves system efficiency. The broad contact surface and precise pitch reduce vibration and extend the service life of pulleys and engaged gears. Customization in belt length and width provides significant flexibility for specialized industrial and automation applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Megadyne PU welded timing belt with H-profile is manufactured from durable thermoplastic polyurethane reinforced with steel or Kevlar cords, providing high tensile strength and long service life. The belt features H-shaped teeth with specific depth and width, ensuring uniform torque and power transmission in industrial systems. The tooth pitch complies with international standards, offering high precision alignment with pulleys and gears. Its operating temperature ranges from -25°C to +80°C, with excellent resistance to wear, oil, and chemical exposure.

Due to its precise engineering and H-profile structure, this belt is suitable for sensitive industrial applications, automated production lines, conveyor systems, and precision drives. The low friction coefficient of polyurethane reduces energy consumption and improves system efficiency. Customization in belt length and width, along with thermal splicing capability, provides high flexibility for specialized industrial environments. The broad tooth contact surface minimizes vibration and extends the service life of pulleys and engaged gears.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Bando T2.5 polyurethane timing belt is made from durable polyurethane with a standard hardness of 80 Shore A and is designed for power transmission in light-duty, precision systems. The belt features precise teeth spaced 2.5 millimeters apart, ensuring perfect synchronization and symmetry on pulleys. Internal cords are made of high-strength fiberglass, maintaining longitudinal stability throughout its service life. Belt length and width can be customized for various industrial applications, and its high precision reduces slippage while improving power transmission efficiency.

This timing belt operates effectively within a temperature range of minus 30 to plus 80 degrees Celsius, maintaining stability across diverse industrial environments. Its polyurethane resistance to oils, ozone, and common chemicals extends operational lifetime. The precise tooth structure and smooth surface reduce friction and minimize noise during operation. Its main applications include precision equipment, packaging machines, textile machinery, and production lines requiring clean and accurate performance.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

A rubber timing belt is one of the most commonly used types of belts in power transmission systems, specifically designed to precisely synchronize the crankshaft and camshaft in internal combustion engines. It is made from heat-resistant, wear-resistant, and chemically stable rubber, often reinforced with fibers such as fiberglass or aramid to enhance tensile strength and dimensional stability. The internal teeth of the belt are precisely engineered to fit into pulley grooves, enabling slip-free power transfer with high timing accuracy.

Due to its high flexibility, low operational noise, and lighter weight compared to metal chains or belts, the rubber timing belt is a preferred choice for many vehicles and light machinery. However, it requires periodic inspection and replacement based on operating conditions and the manufacturers recommendations, as sudden belt failure can cause serious engine damage. Using a high-quality belt that meets the engine’s technical specifications ensures precise timing performance, optimized fuel consumption, and reduced overall component wear.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Megadyne PU welded timing belt RPP5 is manufactured from durable thermoplastic polyurethane reinforced with steel or Kevlar cords, providing high tensile strength and long-lasting durability. The belt features a tooth profile with a 5 millimeter pitch, ensuring uniform torque and power transmission in small to medium industrial systems. Its operating temperature range is -20 to +80 degrees Celsius, offering excellent resistance to wear, oil, and moisture. Belt widths typically range from 10 to 50 millimeters, and thermal welding allows the production of customized endless loops.

Due to its precise tooth design and high dimensional accuracy, this belt is ideal for packaging machinery, automated assembly lines, and precision power transmission systems. The polyurethane compound with a low friction coefficient reduces energy consumption and improves system efficiency. The tooth contact surface ensures uniform force distribution and minimizes vibration at high speeds. Customization in belt length and width provides significant flexibility for specialized industrial applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Bando DH timing belt is made of neoprene rubber reinforced with glass fiber and polyester cords, providing high tensile strength and excellent dimensional stability. The belt teeth are designed with a pitch ranging from 8 to 14 millimeters to ensure precise and uniform power transmission. Its tensile strength is measured between 90 and 120 newtons per millimeter of belt width, with a surface friction coefficient of approximately 0.3. The operating temperature range is from -20 to +100 degrees Celsius, and heat-resistant models can operate effectively up to 120 degrees.

A key feature of the Bando DH timing belt is its high positional accuracy and stable performance at high speeds. It can handle rotational speeds up to 10,000 revolutions per minute, with widths ranging from 10 to 50 millimeters. Standard belt lengths are produced between 200 and 2000 millimeters, and the tooth design reduces vibration and noise to less than 70 decibels. These characteristics make the Bando DH timing belt ideal for high-efficiency industrial machinery requiring precise power transmission.

| |

| power-belt | 021-22087856 |

| ebtekarsanat |

| Iran |

| 021-33990391 |

A timing belt is a precision power transmission component made from heat resistant rubber reinforced with fibers such as fiberglass or aramid. The belt typically has a thickness between 6 and 12 millimeters and a width between 20 and 35 millimeters, and it features HTD or STD tooth profiles. Tooth hardness ranges from 70 to 85 Shore A and the belt withstands temperatures from 90 to 120 degrees Celsius. The inner surface includes a low friction nylon coating that improves cyclic durability. This structure ensures synchronized motion between the crankshaft and camshaft.

A timing belt usually withstands tensile forces of 1500 to 3000 newtons and is manufactured with a length tolerance of less than 0.5 percent. Longitudinal reinforcement fibers provide dimensional stability at high rotational speeds and prevent tooth pitch deviation. The belt delivers consistent performance at operating speeds of 3000 to 6000 rpm. Many belts are produced using HNBR rubber to improve resistance to oil and ozone. The precise tooth design prevents slippage and reduces power transmission losses.

.jpg?width=160&height=160&cropratio=160:160&image=/admin/uploads/تسمه-تایم-تسمه-تایمینگ--ابتکار-صنعت-51-u2231-تسمه تایم (تسمه تایمینگ).jpg&url=/admin/uploads/تسمه-تایم-تسمه-تایمینگ--ابتکار-صنعت-51-u2231-تسمه تایم (تسمه تایمینگ).jpg)

.jpg?width=300&height=300&cropratio=300:300&image=/admin/uploads/تسمه-تایم-تسمه-تایمینگ--ابتکار-صنعت-51-u2231-تسمه تایم (تسمه تایمینگ).jpg&url=/admin/uploads/تسمه-تایم-تسمه-تایمینگ--ابتکار-صنعت-51-u2231-تسمه تایم (تسمه تایمینگ).jpg) | |

| ebtekarsanat | 021-33990391 |

| power-belt |

| Iran |

| 021-22087856 |

The Megadyne double-sided timing belt model T10 260 DD is made of thermoplastic polyurethane with a hardness of 92 Shore A, featuring 40-degree angled teeth with a 10 mm pitch. The total belt length is 260 mm, containing 26 teeth that provide precise power transmission and synchronous motion in both directions. The overall thickness is 5.5 mm, and the width typically ranges from 15 to 25 mm. Internal reinforcement cords are made of stainless steel or fiberglass to ensure high tensile strength and long-term dimensional stability. This belt is suitable for industrial machinery, precision automation systems, and robotic equipment.

The Megadyne T10 260 DD double-sided timing belt performs reliably within a temperature range of -25°C to +80°C. Its polyurethane surface is resistant to abrasion, oils, and mild chemicals. Power transmission efficiency exceeds 97%, with very low operational noise. This belt is designed for applications requiring precise synchronization and bidirectional motion, delivering dependable performance in medium to high-speed industrial systems.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Megadyne double-sided timing belt model T10 530 DD is made of thermoplastic polyurethane with a hardness of 92 Shore A, featuring 40-degree angled teeth with a 10 mm pitch. The total belt length is 530 mm, containing 53 precise teeth that ensure accurate power transmission and synchronous motion in both directions. The overall thickness is 5.5 mm, and the width typically ranges from 15 to 30 mm. Internal reinforcement cords are made of stainless steel or fiberglass to maintain long-term tensile strength and dimensional stability. This belt is suitable for industrial machinery, automation systems, and robotic equipment.

The Megadyne T10 530 DD double-sided timing belt performs reliably within a temperature range of -25°C to +80°C. Its polyurethane surface is resistant to abrasion, oils, and mild chemicals. Power transmission efficiency exceeds 97%, with very low operational noise. This belt is designed for applications requiring precise synchronization and bidirectional motion, delivering dependable performance in medium to high-speed industrial systems.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Megadyne PU welded timing belt RPP8 is manufactured from durable thermoplastic polyurethane reinforced with steel or Kevlar cords, providing high tensile strength and long-lasting durability. The belt features a tooth profile with an 8 millimeter pitch, ensuring uniform torque and power transmission in small to medium industrial systems. Its operating temperature range is -20 to +80 degrees Celsius, with excellent resistance to wear, oil, and moisture. Belt widths typically range from 10 to 50 millimeters, and thermal welding enables the production of endless loops.

Due to its precise engineering and high dimensional accuracy, this belt is an ideal solution for packaging machinery, automated assembly lines, and precision power transmission systems. The tooth design ensures uniform force distribution and reduces vibration at high speeds. The polyurethane compound with a low friction coefficient minimizes energy consumption and improves system efficiency. Customization in belt length and width provides significant flexibility for specialized industrial applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Megadyne PU welded timing belt TL20 is manufactured from thermoplastic polyurethane reinforced with steel or Kevlar cords, ensuring mechanical strength and long-lasting durability. The belt features a precise tooth profile with a 20 millimeter pitch, allowing power transmission in heavy-duty industrial systems and high-torque production lines. Its operating temperature range is -20 to +80 degrees Celsius, with excellent resistance against wear, oil, and moisture. Standard widths range from 25 to 150 millimeters, and thermal welding enables the production of endless loops.

Due to its deep tooth design and large pitch, this belt is capable of transmitting power at high speeds and under heavy loads. Its outstanding dimensional accuracy reduces vibration and extends the service life of pulleys and engaged components. The polyurethane compound with its low friction coefficient minimizes energy losses and enhances system efficiency. Furthermore, customization in both belt length and width provides high flexibility for specialized industrial and automation applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The MEGADYNE timing belt by the meter is an advanced and flexible solution for power transmission in industrial machinery, offering the convenience of being cut and adjusted to the desired length based on user requirements. These belts are typically made from high-quality, wear-resistant polyurethane, which provides excellent durability against abrasion, tearing, oils, and industrial chemicals. The inner core of MEGADYNE belts is reinforced with steel or aramid cords to maintain long-term tensile stability and ensure precise motion control while preserving flexibility.

The toothed surface of these belts is engineered with precision using standard profiles such as T, AT, or HTD to maximize engagement with timing pulleys and eliminate slippage. These timing belts by the meter are ideal for use in conveyor systems, automation equipment, industrial printers, and packaging machines. The ability to customize length and easily fabricate closed-loop belts is another key technical advantage, making them a perfect choice for continuous and adaptable production lines.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Megadyne PU welded timing belt AT10 is manufactured from durable thermoplastic polyurethane reinforced with steel or Kevlar cords, providing high mechanical strength and stability. The belt features a precise 10 millimeter pitch tooth profile, enabling accurate power transmission under heavy-duty working conditions. Its operating temperature range is -20 to +80 degrees Celsius, offering excellent resistance to wear, oil, and moisture. Standard widths vary from 16 to 100 millimeters, and thermal welding allows the production of endless loop belts.

Thanks to its engineered AT tooth design, this belt is capable of transmitting uniform torque at high speeds and under heavy industrial loads. Its high dimensional accuracy minimizes vibration and extends the service life of pulleys and engaged gears. The polyurethane compound with its low friction coefficient reduces energy losses and improves overall system efficiency. Additionally, customization in both length and width provides significant flexibility for specialized industrial applications and production lines.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Megadyne polyurethane timing belt model AT10 800 is made from thermoplastic polyurethane with a hardness of 92 Shore A, featuring 40-degree angled teeth with a 10 mm pitch. The total belt length is 800 mm, containing 80 precision teeth that ensure accurate power transmission and synchronous motion. The overall thickness is 5.5 mm, and the width ranges between 15 and 30 mm depending on the application. Internal reinforcement cords are made of stainless steel or fiberglass to provide high tensile strength and long-term dimensional stability. This belt is suitable for industrial machinery, CNC equipment, and precision automation systems.

The Megadyne AT10 800 timing belt operates reliably within a temperature range of -25°C to +80°C. Its polyurethane surface is resistant to abrasion, oils, and mild chemicals. Power transmission efficiency exceeds 97%, with very low operational noise. The belt is designed for applications requiring precise synchronization and smooth motion, delivering dependable performance in medium to high-speed industrial systems.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Megadyne polyurethane timing belt model AT10 500 is made of thermoplastic polyurethane with a hardness of 92 Shore A, featuring 40-degree angled teeth with a 10 mm pitch. The total belt length is 500 mm, containing 50 precision teeth that ensure accurate power transmission and synchronous motion. The overall thickness is 5.5 mm, and the width varies between 15 and 30 mm depending on the application. Internal reinforcement cords are made of stainless steel or fiberglass to provide high tensile strength and long-term dimensional stability. This belt is suitable for industrial machinery, CNC equipment, and precision automation systems.

The Megadyne AT10 500 timing belt performs reliably within a temperature range of -25°C to +80°C. Its polyurethane surface is resistant to abrasion, oils, and mild chemicals. Power transmission efficiency exceeds 97%, with very low operational noise. This belt is designed for applications requiring precise synchronization and smooth motion, delivering dependable performance in medium to high-speed industrial systems.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Megadyne PU welded timing belt ATL5 is manufactured from thermoplastic polyurethane reinforced with steel or Kevlar cords, providing high tensile strength and long-lasting durability. The belt features a precise 5 millimeter pitch tooth profile, designed for accurate power transmission in small to medium-sized systems. Its operating temperature range is -20 to +80 degrees Celsius, with excellent resistance to wear, oil, and moisture. Standard widths range from 10 to 50 millimeters, and thermal welding allows production of endless loop configurations.

Due to its high dimensional accuracy and excellent flexibility, this belt is ideally suited for packaging machinery, medical equipment, and light assembly lines. The precise tooth geometry ensures uniform power transmission and reduces vibration at higher speeds. The polyurethane compound with a low friction coefficient minimizes energy losses and increases overall system efficiency. Furthermore, customization in both belt length and width provides greater adaptability for specialized industrial applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Megadyne double-sided timing belt model T10 700 DD is made of thermoplastic polyurethane with a hardness of 92 Shore A, featuring 40-degree angled teeth with a 10 mm pitch. The total belt length is 700 mm, containing 70 precise teeth that ensure accurate power transmission and synchronous motion in both directions. The overall thickness is 5.5 mm, and the width typically ranges from 15 to 30 mm. Internal reinforcement cords are made of stainless steel or fiberglass to ensure long-term tensile strength and dimensional stability. This belt is suitable for industrial machinery, automation systems, and robotic equipment.

The Megadyne T10 700 DD double-sided timing belt operates reliably within a temperature range of -25°C to +80°C. Its polyurethane surface resists abrasion, oils, and mild chemicals. Power transmission efficiency exceeds 97%, with very low operational noise. This belt is designed for applications requiring precise synchronization and bidirectional motion, delivering dependable performance in medium to high-speed industrial systems.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Megadyne PU welded timing belt TK10 K6 is manufactured from thermoplastic polyurethane reinforced with steel or Kevlar cords to deliver high mechanical strength and durability. It features a precise tooth profile with a 10 millimeter pitch and a special K6 design, ensuring uniform power transmission under heavy-duty operating conditions. The operating temperature range is -20 to +80 degrees Celsius, offering resistance to wear, moisture, and oil. Belt widths are available from 20 to 100 millimeters and can be thermally welded into endless loops.

Due to its high tensile strength and dimensional accuracy, this belt is an excellent choice for packaging machines, production lines, and industrial power transmission systems. The precise tooth geometry provides uniform load distribution and reduces vibration at higher speeds. The polyurethane compound with its low friction coefficient minimizes energy losses and increases system efficiency. Additionally, customization in belt length and width provides greater flexibility for specialized industrial applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Megadyne PU welded timing belt ATK10 K13 is made of thermoplastic polyurethane reinforced with steel or Kevlar cords, ensuring high tensile strength and long-lasting durability. The belt features a tooth profile with a 10 to 13 millimeter pitch, designed for power transmission in heavier-duty systems. Its operating temperature range is -20 to +80 degrees Celsius, offering strong resistance against wear, oil, and moisture. Standard belt widths are produced between 25 and 100 millimeters, with thermal welding capability for endless loop configurations.

Due to its precise tooth design and broad contact surface, this belt is suitable for transmitting high torques in industrial packaging machinery, production lines, and robotic equipment. Its excellent dimensional accuracy minimizes vibration and increases the service life of engaged components. The combination of high-performance polyurethane and reinforced cords ensures stable operation at high speeds and under heavy loads. Customization in both belt length and width enhances its application flexibility.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Megadyne welded timing belt HTD 8M is manufactured from reinforced polyurethane with helical steel cords and designed for power transmission under medium to heavy loads. The belt features an 8 millimeter pitch and a curvilinear tooth profile, ensuring uniform load distribution and reducing stress concentration during operation. High tensile strength of the embedded cords prevents elongation and guarantees positioning accuracy in motion control systems. Its operating temperature range from minus 20 to plus 100 degrees Celsius allows reliable use in diverse industrial environments.

The surface of the Megadyne welded timing belt HTD 8M is resistant to abrasion and oil, making it suitable for medium to high speed production lines. Endless welding capability enables easy installation without mechanical joints. Transmission efficiency above 97 percent and low noise operation improve productivity and extend the service life of mechanical components. Designed according to DIN ISO 13050 standards, this belt is fully compatible with standardized HTD pulleys.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Megadyne polyurethane timing belt model T2.5 1185 is made from thermoplastic polyurethane with high mechanical strength and minimal elongation. The tooth pitch is 2.5 mm, and the total number of teeth over its 1185 mm length is 474. The overall belt thickness is 1.3 mm, and the width varies between 6 and 25 mm depending on the application. The internal reinforcement consists of stainless steel cords, ensuring dimensional stability and precise torque transmission. This belt is suitable for precision motion systems, industrial printers, CNC machines, and automation equipment.

The Megadyne T2.5 1185 timing belt operates reliably within a temperature range of -25°C to +80°C. The polyurethane surface has a hardness of 92 Shore A, offering excellent resistance to abrasion, oils, and mild chemicals. Its low noise level and transmission efficiency above 98% are key advantages. Designed for continuous operation at high speeds, this belt provides exceptional synchronization accuracy, making it ideal for positioning and timing control applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Bando DXL double-sided polyurethane timing belt is made from high-quality polyurethane and designed for power transmission in serpentine drive systems requiring clean and quiet operation. The internal tensile cord is made of Aramid, providing very high tensile strength and minimal elongation under load. The top and bottom teeth are precision-molded to ensure full symmetry and exact synchronization between both sides. Belt length, width, and tooth count can be customized for industrial applications, and it can be used in medium to high load systems.

This double-sided timing belt operates effectively within a temperature range of minus 30 to plus 80 degrees Celsius, maintaining stability in diverse industrial environments. Its polyurethane resistance to oils, ozone, and common chemicals extends operational lifetime. Internal fiberglass cords ensure longitudinal stability and enable the belt to withstand high loads. The belt is ideal for household appliances, office equipment, and production lines requiring extremely clean and quiet performance.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Megadyne PU welded timing belt TL10 is made of thermoplastic polyurethane reinforced with steel or Kevlar cords, ensuring high tensile strength and superior wear resistance. The belt features a 10 millimeter pitch tooth profile, designed for power transmission in medium-duty industrial machines and precision production lines. Its operating temperature range is -20 to +80 degrees Celsius, offering excellent resistance to oil, moisture, and abrasion. Standard widths range from 20 to 100 millimeters, and thermal welding allows the production of endless loop configurations.

Due to its precisely engineered tooth design, this belt provides uniform torque transmission at high speeds under medium to heavy load conditions. Its dimensional accuracy reduces vibration and extends the service life of engaged pulleys. The polyurethane compound with its low friction coefficient minimizes energy losses and improves overall system efficiency. Furthermore, customization in both belt length and width offers greater flexibility for specialized industrial applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Bando DT10 double-sided polyurethane timing belt is manufactured from high-quality polyurethane and designed for power transmission in serpentine drive systems with medium to heavy loads. The top and bottom teeth are precision-molded to ensure full synchronization and perfect symmetry between both sides of the belt. Internal cords are made of durable fiberglass, providing longitudinal stability and enabling the belt to withstand high industrial loads. Belt length, width, and tooth count can be customized to meet specific industrial requirements.

This double-sided timing belt operates effectively within a temperature range of minus 30 to plus 80 degrees Celsius, maintaining stability across diverse industrial environments. Its polyurethane resistance to oils, ozone, and common chemicals extends operational lifetime. The precise tooth design and smooth surface reduce internal friction and minimize noise during operation. The belt is ideal for household appliances, office equipment, and production lines requiring clean and quiet performance.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The DAYCO timing belt by the meter is a high-performance power transmission product engineered with advanced technology and durable materials to ensure precise and stable operation in industrial environments. Made from reinforced rubber and strong fibers such as fiberglass or aramid, this belt is designed to withstand high pressure, tension, and harsh working conditions. Its open-ended, customizable format allows for cutting to specific lengths, making it suitable for a wide range of specialized industrial applications.

The belt’s tooth profile is manufactured to precise standards to ensure uniform engagement with timing pulleys, eliminating slippage and motion errors. It offers excellent resistance to high temperatures, industrial oils, abrasion, and humidity, making it an ideal choice for continuous production lines, packaging machines, CNC equipment, and automation systems. Dimensional stability, long service life, and quiet operation are among its key technical advantages that distinguish it from other products in the market.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Megadyne PU welded timing belt T20 is made from high strength thermoplastic polyurethane and engineered for heavy torque transmission in industrial machinery. The belt features a 20 millimeter pitch with reinforced teeth, reducing slippage and enhancing positioning accuracy in power transmission systems. Embedded helical steel cords provide stable tensile strength and resistance to deformation. Its operating temperature range from minus 30 to plus 80 degrees Celsius allows reliable use in harsh and diverse industrial environments.

The outer surface of the Megadyne PU welded timing belt T20 is resistant to abrasion, oils, and chemicals, making it suitable for high speed production lines. Endless welding capability enables fast installation without mechanical fasteners. Transmission efficiency above 98 percent and low noise operation improve productivity and extend equipment lifespan. Designed according to DIN ISO 5296 standards, this belt ensures full compatibility with standardized timing pulleys and precise system performance.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Megadyne polyurethane timing belt model AT10 370 is made of thermoplastic polyurethane with a hardness of 92 Shore A, featuring 40-degree angled teeth with a 10 mm pitch. The total belt length is 370 mm, with 37 teeth providing precise power transmission and synchronous motion. The overall belt thickness is 5.5 mm, and the width typically ranges from 15 to 30 mm. Internal reinforcement cords are made of stainless steel or fiberglass, ensuring high tensile strength and dimensional stability. This belt is suitable for power transmission in industrial machinery, automation systems, and CNC equipment.

The Megadyne AT10 370 timing belt operates reliably within a temperature range of -25°C to +80°C. Its polyurethane surface is designed to resist abrasion, oils, and mild chemicals. Power transmission efficiency exceeds 97%, with very low operational noise. The belt is engineered for systems requiring precise synchronization and smooth motion, delivering dependable performance in medium to high-speed industrial applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Bando DT5 double-sided polyurethane timing belt is made from high-quality polyurethane and designed for power transmission in serpentine drive systems. The belt features precise top and bottom teeth, ensuring perfect symmetry and exact synchronization between both sides. Internal cords are made of durable fiberglass, providing longitudinal stability under various operating conditions and enabling the belt to withstand high industrial loads. Belt length, width, and tooth count can be customized to meet diverse industrial requirements.

This double-sided timing belt operates effectively within a temperature range of minus 30 to plus 80 degrees Celsius, maintaining stability across various industrial environments. Its high polyurethane resistance to oils, ozone, and common chemicals extends operational lifetime. The precise tooth structure reduces internal friction and minimizes noise during operation. The belt is ideal for office equipment, household appliances, and production lines requiring clean and quiet performance.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Megadyne polyurethane timing belt model T2.5 120 is made from thermoplastic polyurethane with a hardness of 92 Shore A and a 2.5 mm tooth pitch. The total belt length is 120 mm, containing 48 precision-molded teeth that ensure accurate power transmission. The overall thickness is 1.3 mm, and the width typically ranges between 6 and 10 mm. Internal reinforcement with stainless steel cords provides high tensile strength and long-term dimensional stability. This belt is ideal for small motion mechanisms, automation devices, robotics, and precision instruments.

The Megadyne T2.5 120 timing belt performs reliably within a temperature range of -25°C to +80°C. Its polyurethane surface resists wear, oils, and mild chemicals. Power transmission efficiency exceeds 98%, with minimal operational noise. The belt is designed for systems requiring precise synchronization and smooth rotation. Its high pitch accuracy and resistance to deformation make it highly dependable for positioning control and miniature drive applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Megadyne PU welded timing belt AT5 is produced from high density thermoplastic polyurethane and engineered for accurate torque transmission in industrial systems. The belt features a 5 millimeter pitch with reinforced trapezoidal teeth, improving load capacity and minimizing slippage during operation. Strong embedded steel cords provide stable tensile strength and resistance to deformation under continuous stress. Its operating temperature range from minus 25 to plus 80 degrees Celsius supports use in diverse manufacturing and laboratory environments.

he outer surface of the Megadyne PU welded timing belt AT5 is resistant to abrasion, oils, and chemicals, ensuring long service life under continuous duty. Endless welding capability allows easy installation and maintenance without mechanical fasteners. Transmission efficiency above 97 percent and low noise operation enhance productivity in production lines. Precision engineering according to DIN ISO 5296 guarantees full compatibility with standardized timing pulleys.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

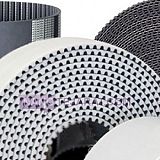

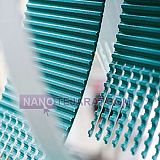

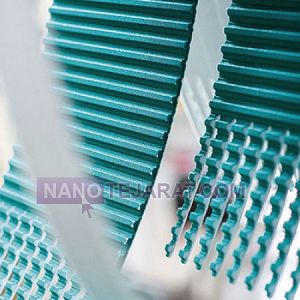

Timing belts are engineered from polyurethane or natural rubber materials, capable of withstanding temperatures ranging from -20°C to 100°C. Belt widths typically range from 6 to 50 millimeters, with thicknesses varying between 3 and 15 millimeters. These belts feature precisely engineered teeth with depths between 2 and 6 millimeters, ensuring accurate synchronization and preventing slippage in power transmission systems. Tensile strength ranges from 2000 to 6000 Newtons per centimeter of width, enhanced by internal reinforcement with polyester fibers or steel cords.

The internal reinforcement system of timing belts is commonly made from Aramid fibers or stainless steel, guaranteeing high durability and flexibility. These belts resist industrial oils, abrasion, and ultraviolet radiation, with an estimated service life exceeding 7 years. Compliance with ISO 9001 and DIN EN standards during production ensures the quality and precise performance of timing belts across various industrial machinery applications.

.jpg?width=160&height=160&cropratio=160:160&image=/admin/uploads/تسمه-صنعتی-تایمینگ-Industrial-timing-belts-پاور-بلت-94-u3092-c577ab-New Project (5).jpg&url=/admin/uploads/تسمه-صنعتی-تایمینگ-Industrial-timing-belts-پاور-بلت-94-u3092-c577ab-New Project (5).jpg)

.jpg?width=300&height=300&cropratio=300:300&image=/admin/uploads/تسمه-صنعتی-تایمینگ-Industrial-timing-belts-پاور-بلت-94-u3092-c577ab-New Project (5).jpg&url=/admin/uploads/تسمه-صنعتی-تایمینگ-Industrial-timing-belts-پاور-بلت-94-u3092-c577ab-New Project (5).jpg) | |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Megadyne polyurethane timing belt model T5 200 is made from thermoplastic polyurethane with a hardness of 92 Shore A, featuring 40-degree angled teeth with a 5 mm pitch. The total belt length is 200 mm, containing 40 precision teeth that ensure accurate power transmission and synchronous motion. The overall thickness is 3.5 mm, and the width typically ranges from 6 to 15 mm. Internal reinforcement cords are made of stainless steel or fiberglass to provide high tensile strength and long-term dimensional stability. This belt is suitable for small machinery, automation equipment, and precision robotics.

The Megadyne T5 200 timing belt performs reliably within a temperature range of -25°C to +80°C. Its polyurethane surface is resistant to abrasion, oils, and mild chemicals. Power transmission efficiency exceeds 97%, with very low operational noise. The belt is designed for systems requiring precise synchronization and smooth motion, delivering dependable performance in medium-speed industrial applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Megadyne polyurethane timing belt model T5 120 is made from thermoplastic polyurethane with a hardness of 92 Shore A, featuring 40-degree angled teeth with a 5 mm pitch. The total belt length is 120 mm, containing 24 precision teeth that ensure accurate power transmission and synchronous motion. The overall thickness is 3.5 mm, and the width typically ranges from 6 to 15 mm. Internal reinforcement cords are made of stainless steel or fiberglass to maintain long-term tensile strength and dimensional stability. This belt is suitable for small machinery, automation equipment, and precision robotics.

The Megadyne T5 120 timing belt operates reliably within a temperature range of -25°C to +80°C. Its polyurethane surface is resistant to abrasion, oils, and mild chemicals. Power transmission efficiency exceeds 97%, with very low operational noise. The belt is designed for systems requiring precise synchronization and smooth motion, delivering dependable performance in medium-speed industrial applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The OPTIBELT timing belt designed for flour mills and silos is manufactured with a durable structure to ensure stable performance. Made from high-quality polyurethane materials, these belts offer excellent resistance to wear, heat, and oils, enabling operation under harsh environmental conditions. The core is reinforced with aramid or steel fibers, guaranteeing high tensile strength and long-term stability, which reduces wear and tear over time. The tooth design is engineered to provide precise power transmission with minimal slippage.

Due to their high durability and extended lifespan, these belts are ideal for power transmission systems in flour mills and dry material storage silos. OPTIBELT’s optimized belt design minimizes maintenance requirements and ensures uninterrupted operation, enhancing production line efficiency. Additionally, these belts can be customized in length and are compatible with various pulley types, providing greater flexibility and improved performance in industrial systems.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Bando 450DH100G industrial timing belt is a precision toothed belt designed for shaft synchronization and slip-free power transmission. The belt length is 450 millimeters, width is 100 millimeters, and the tooth pitch in the DH series is 8 millimeters. The semicircular tooth profile ensures uniform engagement and reduces mechanical noise. The use of fiberglass tensile cords and durable elastomer in the body provides dimensional stability and high endurance under cyclic loading conditions.

The Bando 450DH100G industrial timing belt can operate in temperatures ranging from minus 20 to plus 100 degrees Celsius, delivering excellent performance in heavy-duty applications. Its abrasion resistance and stability against oil and dust make it suitable for machinery with continuous duty cycles. The optimized friction surface of the teeth reduces energy consumption and extends bearing life. These features make the Bando belt widely used in packaging machines, material handling systems, and precision equipment.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Megadyne PU welded timing belt T5 is manufactured from high quality thermoplastic polyurethane and engineered for precise power transmission in light to medium duty applications. The belt features a 5 millimeter pitch with standardized tooth profile ensuring full compatibility with conventional timing pulleys. Embedded helical steel cords reinforce tensile strength and minimize elongation under load. Its operating temperature range from minus 20 to plus 80 degrees Celsius supports use in a wide range of industrial environments.

The surface of the Megadyne PU welded timing belt T5 is wear resistant and suitable for precision automation, medical devices, and packaging machinery. Endless welding capability allows easy installation without mechanical joints. High transmission efficiency above 96 percent and low noise operation improve productivity and extend equipment lifespan. Designed in compliance with DIN ISO 5296 standards, this belt is a reliable choice for applications requiring superior accuracy.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Megadyne PU welded timing belt AT20 is manufactured from high strength thermoplastic polyurethane and designed for heavy torque transmission. The belt features a 20 millimeter pitch and precise tooth geometry that reduces slippage and enhances positioning accuracy. Longitudinal tension is reinforced with embedded steel cords to minimize deformation under continuous load. Its operating temperature range from minus 30 to plus 80 degrees Celsius allows reliable use in diverse industrial environments.

The outer surface of the Megadyne PU welded timing belt AT20 is abrasion and oil resistant, making it suitable for high speed production lines. This belt supports endless welding, enabling quick installation and replacement without complex tools. Low noise operation and power transmission efficiency above 98 percent extend the service life of mechanical components. With a robust structure and standardized dimensions according to DIN ISO 5296, it is an ideal choice for heavy duty industrial machinery.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Bando DL timing belt is made of neoprene rubber reinforced with glass fiber and nylon, providing high tensile strength. The belt teeth feature a semi-circular design with a standard pitch ranging from 3 to 14 millimeters, ensuring smooth power transmission. Its tensile strength is measured between 70 and 100 newtons per millimeter of width, with an average surface friction coefficient of 0.3. The operating temperature range of the Bando DL timing belt is from -30 to +100 degrees Celsius, while heat-resistant models can perform effectively up to 120 degrees.

One of the outstanding features of the Bando DL timing belt is its high positioning accuracy in synchronization systems. This belt operates stably at high speeds up to 12,000 revolutions per minute. The available widths range from 6 to 50 millimeters, and the lengths vary from 200 to 2000 millimeters. The tooth profile is designed to generate vibration noise below 70 decibels, making it highly suitable for high-speed production lines.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Optibelt D5M 1000 double-sided timing belt is made of polyurethane reinforced with steel cord and is endless without joints. The effective length is 1000 mm with a 5 mm tooth pitch. This belt features a D-profile with metric teeth, ensuring precise power transmission with minimal slippage. Standard widths are 16 and 25 mm, with other widths available on request. High tensile strength, long mechanical durability, and excellent dimensional stability are key features of this industrial product.

The D5M 1000 belt offers excellent resistance to wear, oil, and chemicals, with low preload requirements. Steel cord reinforcement ensures low vibration and quiet operation. This belt is ideal for applications requiring precise power transmission and bidirectional synchronization. Open lengths and custom width cutting are available. The PU and steel cord construction reduces wear compared to traditional rubber belts, making it widely used in industrial, automotive, and pharmaceutical applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Optibelt 120 HTD 5M timing belt has an effective pitch length of 120 mm and an HTD profile with a 5 mm tooth pitch. It is manufactured from durable rubber reinforced with fiberglass cords, ensuring high dimensional stability and precise performance. The HTD profile features a curved design that provides smoother power transmission compared to traditional trapezoidal profiles. Standard widths for this belt are 9, 15, and 25 mm, with customized widths available upon request.

This Optibelt timing belt operates within a temperature range of -30 to +100 °C and offers resistance to oil and abrasion. The HTD design evenly distributes load across the teeth, delivering power transmission efficiency above 98 percent. A key feature of the 120 HTD 5M belt is its ability to reduce noise and vibration in industrial drive systems. It is ideal for precise applications such as packaging machinery, CNC equipment, and automation systems, with longer service life compared to conventional timing belts.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Bando KPS8M industrial polyurethane timing belt is made from high-quality polyurethane and features high modulus aramid cords for high torque transmission at low speeds. The belt width is 8 millimeters with an 8-millimeter tooth pitch, designed to fit standard STS pulleys. It can transmit up to five times more power than standard STS belts, while reducing wear and rubber dust for longer service life. Its operating temperature range is between -30 and 80 degrees Celsius, and it demonstrates high chemical resistance to oils and industrial greases.

The flexible construction and durable polyurethane body allow usage in various high-torque industrial drives. The belts inner diameter and bending radius are optimized to minimize mechanical stress. Custom lengths up to 5000 millimeters are available with dimensional accuracy of ±0.2 millimeters. These features enhance energy efficiency, reduce vibration in sensitive mechanical systems, and allow quick, easy installation on pulleys.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Optibelt 320 HTD 8M timing belt is made of polyurethane reinforced with steel cord and is endless without joints. The effective length is 320 mm with an 8 mm tooth pitch. This belt features an HTD profile with trapezoidal metric teeth, ensuring precise power transmission with minimal slippage. Standard widths are 16, 25, and 32 mm, with other widths available on request. High tensile strength, long mechanical durability, and excellent dimensional stability are key features of this industrial product.

The 320 HTD 8M belt offers excellent resistance to wear, oil, and chemicals, with low preload requirements. Steel cord reinforcement ensures low vibration and quiet operation. This belt is ideal for applications requiring precise positioning and power transmission. Open lengths and custom width cutting are available. The PU and steel cord construction reduces wear compared to traditional rubber belts, making it widely used in food, pharmaceutical, and industrial applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Optibelt T10 260 timing belt is made of polyurethane with steel cord and is endless without joints. The effective length is 260 mm with 26 teeth. Standard widths are 16, 25, 32, and 50 mm, with other widths available on request. The standard T10 profile according to DIN 7721 features a trapezoidal metric tooth design, ensuring precise power transmission with minimal slippage. The belt offers high tensile strength, long service life, and can operate in temperatures ranging from -25°C to +80°C.

This belt provides excellent resistance to chemicals, oil, and wear, with low preload requirements. Steel cord reinforcement ensures low vibration and quiet operation. The T10 260 is ideal for applications requiring precise positioning and power transmission. Open lengths and custom width cutting are also available. The PU and steel cord construction reduces wear compared to traditional rubber belts, making it widely used in food, pharmaceutical, and industrial applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Megadyne HTD 14M welded timing belt is a power transmission belt with a standard HTD arc-shaped tooth profile and a 14 mm pitch. It is produced from durable thermoplastic polyurethane reinforced with steel or Kevlar cords, ensuring high mechanical strength and long service life. Its operating temperature range is typically from -20 to +100 degrees Celsius, with excellent dimensional stability under varying load conditions. Belt widths are manufactured from 20 to 115 millimeters and can be thermally welded into endless loops.

Due to its larger cross-section and 14 mm pitch, this belt is capable of transmitting high torques in heavy machinery and industrial production lines. The precise tooth design ensures uniform stress distribution and prevents slippage at high speeds. The low friction coefficient of polyurethane reduces energy losses and increases system efficiency. Customization options in belt length and width provide significant flexibility for different applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Optibelt 288 HTD 8M timing belt is made of polyurethane reinforced with steel cord and is endless without joints. The effective length is 288 mm with an 8 mm tooth pitch. The HTD profile features trapezoidal metric teeth, ensuring precise power transmission with minimal slippage. Standard widths are 16, 25, and 32 mm, with other widths available on request. High tensile strength, excellent dimensional stability, and long mechanical durability are key features of this industrial product.

The 288 HTD 8M belt offers excellent resistance to wear, oil, and chemicals, with low preload requirements. Steel cord reinforcement ensures low vibration and quiet operation. This belt is suitable for applications requiring precise positioning and power transmission. Open lengths and custom width cutting are also available. The PU and steel cord construction reduces wear compared to traditional rubber belts, making it widely used in food, pharmaceutical, and industrial applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Optibelt D5M 1200 double-sided timing belt is made of polyurethane reinforced with steel cord and is endless without joints. The effective length is 1200 mm with a 5 mm tooth pitch. The D-profile with metric teeth ensures precise power transmission with minimal slippage. Standard widths are 16 and 25 mm, with other widths available on request. High tensile strength, long mechanical durability, and excellent dimensional stability are key features of this industrial product.

The D5M 1200 belt offers excellent resistance to wear, oil, and chemicals, with low preload requirements. Steel cord reinforcement ensures low vibration and quiet operation. This belt is ideal for applications requiring precise power transmission and bidirectional synchronization. Open lengths and custom width cutting are available. The PU and steel cord construction reduces wear compared to traditional rubber belts, making it widely used in industrial, automotive, and pharmaceutical applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Optibelt D5M 2000 double-sided timing belt is made of polyurethane reinforced with steel cord and is endless without joints. The effective length is 2000 mm with a 5 mm tooth pitch. The D-profile with metric teeth ensures precise power transmission with minimal slippage. Standard widths are 16 and 25 mm, with other widths available on request. High tensile strength, long mechanical durability, and excellent dimensional stability are key features of this industrial product.

The D5M 2000 belt offers excellent resistance to wear, oil, and chemicals, with low preload requirements. Steel cord reinforcement ensures low vibration and quiet operation. This belt is ideal for applications requiring precise power transmission and bidirectional synchronization. Open lengths and custom width cutting are available. The PU and steel cord construction reduces wear compared to traditional rubber belts, making it widely used in industrial, automotive, and pharmaceutical applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Optibelt 288 HTD 8M timing belt is made of polyurethane reinforced with steel cord and is endless without joints. The effective length is 288 mm with an 8 mm tooth pitch. The HTD profile features trapezoidal metric teeth, ensuring precise power transmission with minimal slippage. Standard widths are 16, 25, and 32 mm, with other widths available on request. High tensile strength, excellent dimensional stability, and long mechanical durability are key features of this industrial product.

The 288 HTD 8M belt offers excellent resistance to wear, oil, and chemicals, with low preload requirements. Steel cord reinforcement ensures low vibration and quiet operation. This belt is suitable for applications requiring precise positioning and power transmission. Open lengths and custom width cutting are also available. The PU and steel cord construction reduces wear compared to traditional rubber belts, making it widely used in food, pharmaceutical, and industrial applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Optibelt T10 340 timing belt is made of polyurethane reinforced with steel cord and is endless without joints. The effective length is 340 mm with 34 teeth. Standard widths are 16, 25, 32, and 50 mm, with other widths available on request. The standard T10 profile according to DIN 7721 features a trapezoidal metric tooth design, ensuring precise power transmission with minimal slippage. The belt offers high tensile strength and can operate in temperatures ranging from -25°C to +80°C.

This belt provides excellent resistance to wear, oil, and chemicals, with low preload requirements. Steel cord reinforcement ensures low vibration and quiet operation. The T10 340 is ideal for applications requiring precise positioning and power transmission. Open lengths and custom width cutting are also available. The PU and steel cord construction reduces wear compared to traditional rubber belts, making it widely used in food, pharmaceutical, and industrial applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Megadyne T5 410 DD double-sided timing belt is made of polyurethane reinforced with fiberglass, with an effective length of 410 millimeters. Its width is 16 millimeters and tooth height 5 millimeters, allowing bidirectional power transmission. Teeth are manufactured with ±0.05 millimeter precision for perfect pulley alignment, and tensile strength reaches 800 Newtons. The belt operates reliably between -30°C and +100°C and resists oils, grease, and industrial chemicals.

Internally, the belt features a fiberglass reinforced core with high-wear polyurethane coating, ensuring over 10,000 hours of operational life under standard conditions. Dual-sided teeth reduce slippage and mechanical noise at high speeds, while optimized tooth geometry increases transmission efficiency up to 98 percent. Fully compliant with ISO 5296 and DIN 7721 standards, it is ideal for precision industrial applications including printing, packaging, and automated production lines.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Optibelt 856 HTD 8M timing belt is made of polyurethane reinforced with steel cord and is endless without joints. The effective length is 856 mm with an 8 mm tooth pitch. This belt features an HTD profile with trapezoidal teeth, ensuring precise power transmission with minimal slippage. Standard widths are 16, 25, and 32 mm, with other widths available on request. High tensile strength, long mechanical durability, and excellent dimensional stability are key features of this industrial product.