| kariz-industrial-equipment |

| Iran |

| 021-55400161 |

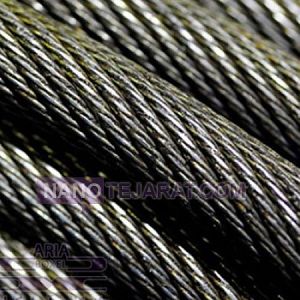

Import, production and distribution of galvanized steel wire ropes in Kariz industrial equipment.

Sale of steel towing wire

Sale of galvanized towing wire

Sale of hot galvanized towing wire

Sale of cold galvanized towing wire

Sale of galvanized steel towing wire

Sale of galvanized hemp wire

Sale of galvanized towing wire 6*19

Sale of galvanized towing wire 6*37

Sale of galvanized towing wire 6*36

Sale of galvanized towing wire 25*6

Sale of galvanized towing wire 8*25

Steel wire ropes have a much higher tensile strength than stainless steel wire ropes, but one of the weaknesses of steel wire ropes is their low resistance to environmental conditions such as humidity, which causes them to oxidize.

Galvanized wire ropes include many textures, structures and specifications. Stainless steel wire ropes have anti-rust properties due to the presence of chromium and nickel in their chemical structure. On this basis, galvanized steel towing wire is used.

In the production of towing wire, steel is used as the main alloy. The iron element with a very high percentage is the main constituent of this type of steel ropes, which includes metallic elements with unstable electrons and prone to covalent bonding with oxygen. Therefore, steel towing wire without galvanized plating will

| |

| kariz-industrial-equipment | 021-55400161 |

| Tarom-boxel |

| Iran |

| 02155429480 |

The 12 mm galvanized non-rotating all-steel tower crane wire rope with 19x7 construction and a tensile strength of 1770 N/mm² is designed for industrial applications and secure tower crane connections. It consists of seven strands, each containing 19 wires, forming a compact and highly durable structure. The nominal diameter of 12 millimeters provides a tensile strength between 75 and 85 kilonewtons, making it suitable for carrying heavy tower crane loads and elevator cabins up to 1000 kilograms. The galvanized coating enhances corrosion and wear resistance, ensuring smooth and safe operation under harsh environmental conditions.

The approximate weight per meter of the 12 mm 19x7 galvanized all-steel non-rotating rope ranges from 0.60 to 0.64 kilograms and is suitable for sheaves with a minimum diameter of 450 millimeters. The WLL Working Load Limit is approximately 600 to 700 kilograms, while the MBL Maximum Breaking Load ranges from 42 to 50 kilonewtons. These specifications ensure safe, stable, and reliable performance under continuous and fluctuating loads, reducing the risk of over-tensioning and structural damage.

The outer wires are made of carbon steel with a tensile strength of 1770 N/mm², providing high resistance to pressure, wear, and fatigue under repeated lo

| |

| Tarom-boxel | 02155429480 |

| Tarom-boxel |

| Iran |

| 02155429480 |

The 12 mm galvanized Netab wire rope with 19x7 construction and a tensile strength of 1770 N/mm² is designed for elevator applications and tower crane connections. It consists of seven strands, each containing 19 wires, forming a compact and highly durable structure. The nominal diameter of 12 millimeters provides a tensile strength between 75 and 85 kilonewtons, suitable for carrying elevator cabins up to 1000 kilograms and ensuring secure tower crane connections. The galvanized coating enhances corrosion and wear resistance, guaranteeing smooth, safe, and reliable performance in industrial and construction environments.

The approximate weight per meter of the 12 mm 19x7 galvanized Netab rope ranges from 0.60 to 0.64 kilograms and is suitable for sheaves with a minimum diameter of 450 millimeters. The WLL Working Load Limit is approximately 600 to 700 kilograms, while the MBL Maximum Breaking Load ranges from 42 to 50 kilonewtons. These specifications ensure safe and stable operation under continuous and fluctuating loads, reducing the risk of damage due to over-tensioning and providing reliable performance over time.

The outer wires are made of carbon steel with a tensile strength of 1770 N/mm², providing high resistance to wear, pressure, and fatigue under repeated loa

| |

| Tarom-boxel | 02155429480 |

| Tarom-boxel |

| Iran |

| 02155429480 |

The 10 mm galvanized Netab non-rotating wire rope with a tensile strength of 1770 N/mm² is designed for elevator applications and tower crane connections. Its construction is typically 6x19 or 6x37, consisting of six strands with 19 or 37 wires per strand, arranged to minimize rotation under load. The nominal diameter of 10 millimeters provides a tensile strength between 55 and 65 kilonewtons, suitable for carrying elevator cabins up to 800 kilograms and ensuring secure tower crane connections. The galvanized coating offers high corrosion and wear resistance, guaranteeing smooth, safe, and reliable performance in industrial and construction environments.

The approximate weight per meter of the 10 mm non-rotating Netab rope ranges from 0.41 to 0.44 kilograms, suitable for sheaves with a minimum diameter of 400 millimeters. The WLL Working Load Limit is approximately 450 to 550 kilograms, while the MBL Maximum Breaking Load ranges from 36 to 42 kilonewtons. The non-rotating design prevents cable twist during operation, ensuring stable load handling and reducing the risk of uncontrolled rotation or wear during repeated cycles.

The outer wires are made of carbon steel with a tensile strength of 1770 N/mm², providing high wear and pressure resistance. Elongation under tensile

| |

| Tarom-boxel | 02155429480 |

| Tarom-boxel |

| Iran |

| 02155429480 |

The 8 mm galvanized non-rotating wire rope with a tensile strength of 1770 N/mm² is designed for light to medium-duty elevator systems. Its typical construction is 6x19 or 6x37, meaning six strands with 19 or 37 wires per strand. The 8 mm diameter provides a tensile capacity between 36 and 42 kilonewtons, suitable for elevator cabins carrying up to 400 kilograms in 2:1 suspension systems. The galvanized coating enhances corrosion resistance, extends service life in humid or industrial environments, and ensures smooth and safe operation over time.

The approximate weight per meter of the 8 mm non-rotating wire rope is 0.26 to 0.28 kilograms, suitable for sheaves with a minimum diameter of 320 millimeters. The WLL Working Load Limit ranges from 350 to 450 kilograms, while the MBL Maximum Breaking Load is around 36 to 42 kilonewtons. These specifications ensure safe and reliable performance under continuous or fluctuating loads, reducing the risk of damage due to over-tensioning.

The outer wires are made of carbon steel with a tensile strength of 1770 N/mm², providing high resistance to wear and pressure. Elongation under tensile load is approximately 2 to 2.5 percent, with a recommended safety factor between 8 and 12. These features make the 8 mm galvanized Netab wire rope a

| |

| Tarom-boxel | 02155429480 |

| kianbolt |

| Iran |

| 021-55401057 |

پیچ های متری در واقع به شکل یک میله یا راد تمام رزوه تولید می شوند. پیچ متری هم در گرید های آهنی، فولادی خشکه و هم در گرید های استنلس استیل تولید می شود. پیچ های متری اغلب یا با دنده های درشت تولید می شوند و یا با دنده های کبریتی. پیچ متری اغلب در صنایع ساختمانی و در اتصالات تاسیساتی برای اتصال کانال ها و داکت ها مورد استفاده قرار می گیرد.

| |

| kianbolt | 021-55401057 |

| ajax-hex-bolt |

| Iran |

| 021-55429480 |

Galvanized stud bolts are produced with a zinc coating thickness typically ranging from 50 to 100 microns to provide high resistance against corrosion and oxidation. These stud bolts are made from carbon steel with tensile strengths between 60 and 110 ksi approximately 415 to 760 MPa. Common diameters range from 1/4 inch to 2 inches with various lengths available, and threads are manufactured according to ASME B1.1 standards with class 2A or 3A accuracy. The galvanizing process can be hot-dip or electroplating, with hot-dip providing greater environmental resistance. Surface hardness after galvanizing typically ranges from 180 to 250 Brinell.

These stud bolts are widely used in oil, gas, petrochemical industries, and metal structure construction, especially in humid and corrosive environments. Quality control includes coating thickness testing, tensile testing, hardness testing, and non-destructive tests such as penetrant testing PT. Their corrosion resistance significantly increases the service life of connections and reduces maintenance costs. Using galvanized stud bolts in industrial projects improves safety and structural stability of metal frameworks.

| |

| ajax-hex-bolt | 021-55429480 |

| generalsteel |

| Iran |

| 021-55412302 |

Galvanized Allen bolts are typically made from carbon steel grades 8.8 and 10.9, with tensile strength ranging from 800 to 1040 MPa. These bolts have diameters between 4 and 24 millimeters and lengths ranging from 10 to 200 millimeters. They are manufactured according to DIN 912 and ISO 4762 standards and feature an internal hexagonal head with a 90-degree angle. Cold or hot-dip galvanizing increases resistance to corrosion and rust in humid and industrial environments. The coating thickness ranges from 5 to 25 microns, providing long-term protection against oxidation.

The threading of galvanized Allen bolts is produced to DIN and ISO standards with a dimensional tolerance of ±0.15 millimeters. Thread pitch usually ranges from 0.7 to 2.5 millimeters and is available in both full-thread and half-thread variants. Surface hardness after heat treatment and galvanizing reaches 35 to 45 HRC, improving wear resistance and preventing plastic deformation. These bolts are widely used in construction, automotive, and industrial machinery due to their high strength and long-lasting durability, making them ideal for high-stress connections.

| |

| generalsteel | 021-55412302 |

| ajax-hex-bolt |

| Iran |

| 021-55429480 |

Galvanized Allen bolts are typically made from carbon steel grades 8.8 and 10.9, with tensile strengths ranging from 800 to 1040 MPa. The bolt diameters vary from 4 to 24 millimeters, and lengths range between 10 and 200 millimeters. These bolts are manufactured according to DIN 912 and ISO 4762 standards and feature an internal hexagonal head with a 90-degree angle. Cold or hot-dip galvanizing coatings enhance corrosion and rust resistance in humid and industrial environments. Heat treatment improves mechanical strength and durability against dynamic and static loads.

The threads of galvanized Allen bolts are produced with precision tolerances of ±0.15 millimeters based on ISO and DIN standards. Thread pitch typically ranges from 0.7 to 2.5 millimeters and is available in full-thread or half-thread versions. Surface hardness after heat treatment and galvanizing reaches 35 to 45 HRC, providing high wear resistance and preventing plastic deformation. These bolts are widely used in construction, automotive, and industrial equipment sectors for connections requiring high strength and long-lasting durability.

| |

| ajax-hex-bolt | 021-55429480 |

| wikilift |

| Iran |

| 021-55429480 |

Carbon Steel load chain rusts due to having a very high percentage of iron metal element without surface coating. Often, two methods, i.e. surface plating or oven paint, are used to prevent direct contact of water and moisture with the surface of the load chain. Galvanized load chain is plated with a thin coating of Zn metal, which is also called zinc in Farsi. Of course, the process of electroplating steel chains is carried out in two ways: cold galvanizing less thickness and resistance and hot galvanizing more thickness and resistance. The cold galvanized load chain can be seen in silver color and the hot galvanized sample can be seen in matte silver color.

The difference between cold and hot galvanized plating in the surface strengthening of the load chain is in the plating method and temperature.

| |

| wikilift | 021-55429480 |

| akhavan-wire-rope |

| Iran |

| 021-55411976 |

The connecting wire rope on tower cranes is often used in large areas and for lifting loads to high heights. Therefore, the steel wire rope of the tower crane is chosen in such a way that it has a minimum anchor in lifting and is strong against rotation and twisting. The structure of the towing wire of the tower crane is selected as non-rotating or resistant to swing. The two practical structures of the wire rope are as follows:

19X7

35X7

Both structures are made of netable tower crane towing wire and are produced in full steel. In general, fine weaves, i.e. high number of strands and small diameter wires are used in the production of towing wire for tower cranes. This fine texture makes the tower tow wire highly flexible and has a stunning appearance.

| |

| akhavan-wire-rope | 021-55411976 |

| Dena-boxel |

| Iran |

| 021-55406871 |

Hot galvanized steel wire rope has a much more limited use than cold galvanized steel wire rope. In most cases, only special constructions of wire ropes are hot galvanized. Hot galvanized steel wire rope has a much higher environmental resistance than cold galvanized samples in contact with water and industrial corrosives and is seen in matte silver color. Meanwhile, the cold galvanized steel wire rope has a shiny silver surface.

The hot galvanizing plating of the steel wire ropes causes a very thick layer of zinc metal with a thickness between 36 and 100 microns to be placed on the surface of the towing wires. Meanwhile, the thickness of the zinc layer in the cold galvanized plating of the steel wire ropes is about 18 microns.

| |

| Dena-boxel | 021-55406871 |

| Dena-boxel |

| Iran |

| 021-55406871 |

Tower crane wire rope, which is also known as micro-texture, is produced from steel alloys to have the appropriate tensile strength for lifting loads with the tower. Since a high percentage of the steel alloy consists of iron metal, which has unstable electrons, the tower crane wire ropes rust quickly without surface protection.

The towing wire of the tower crane is of the non-rotating type and is often cold galvanized with a thin coating of zinc zinc which has a thickness of 16 to 18 microns. The galvanized plating of the tower crane tow wire has created a relative environmental resistance to rust for the tower crane net tow wire, which performs well if scratched.

| |

| Dena-boxel | 021-55406871 |

| akhavan-wire-rope |

| Iran |

| 021-55411976 |

Range galvanized wire rope includes many wire rope textures and structures. In fact, except for stainless steel towing wire, which has anti-rust properties due to the presence of elements such as chrome and nickel in the structure, most samples of steel towing wire are used in galvanized form. In fact, steel as the main alloy used in the production of wire rope is formed from iron element with a very high percentage, which is a metallic element with unstable electrons and prone to covalent bonding with oxygen. Therefore, the steel towing wire will rust in contact with water, moisture and many acidic and alkaline substances in nature without galvanized plating.

| |

| akhavan-wire-rope | 021-55411976 |

| akhavan-wire-rope |

| Iran |

| 021-55411976 |

To connect different strands of chain to each other or to connect chains to other lifting tools, a piece is needed that acts like a chain but has the ability to open and separate. The steel chain connector actually provides the ability to connect two chains of different sizes to each other or to connect the chain to the hook, hook or sling ring without any problems.

The steel chain link consists of a curved main body, which is produced by hot forging method. G80 grade steel is often used in the production of this body, which has both a medium and high percentage of carbon in the steel alloy, and its mechanical capabilities have increased during hard work.

| |

| akhavan-wire-rope | 021-55411976 |

| hardwire-steel-wire-rope |

| Iran |

| 021-55423008 |

Socket double head restraints are produced in both steel grades and stainless steel grades. The inch and millimeter sizes of double-ended socket clamps are used in the connections of chain slings and towing wires and in order to increase the tension and tension of the connection strings.

The shape of the body of the two-ended socket arrester can be both flat and tubular, and in heavy industries, flat examples of the double-ended socket arrester are often used. The main body of the double-ended socket arrester is produced by hot forging method, and G80 steel grade, which has high tensile strength and surface hardness, is often used in its production.

| |

| hardwire-steel-wire-rope | 021-55423008 |

| akhavan-wire-rope |

| Iran |

| 021-55411976 |

In the oil industry and on drilling rigs, wire ropes with a special structure are used. Drilling towing wire is often used in the 6-strand type, which is made of steel wires with a larger diameter than the wires used in the elevator industry or on towers. excavating wire is used from size 8 mm and above, but it has the maximum amount of use in size 10 mm.

excavating wire rope is used in smaller sizes with a steel core, which has a 6X19 structure and is supplied with the extension IWRC. In larger sizes, the drill string is often used with hemp core, which is used with the suffix FC, which stands for Fiber core.

| |

| akhavan-wire-rope | 021-55411976 |

| Iranallexport |

| Iran |

| 021-55421083 |

Due to the galvanizing process, galvanized steel chains are resistant to rust, erosion and corrosion, and thus have a stronger strength and longer service life.

Galvanized steel chains are produced in different sizes and from 3 mm sizes.

These chains are packed in bags and with different weights.

The price of different types of steel chains fluctuates and varies according to each situation.

Often, smaller chain sizes are more expensive than other sizes.

The type of galvanized, whether hot or cold, is important in choosing the chain as well as in its use, and you should be careful about this.

.jpg?width=160&height=160&cropratio=160:160&image=/admin/uploads/زنجیر-فولادی-گالوانیزه--Galvanized-steel-chain-تجهیزات-صنعتی-ایران-ال-اکسپورت-107-u2553-55adba-unnamed (3).jpg&url=/admin/uploads/زنجیر-فولادی-گالوانیزه--Galvanized-steel-chain-تجهیزات-صنعتی-ایران-ال-اکسپورت-107-u2553-55adba-unnamed (3).jpg)

.jpg?width=300&height=300&cropratio=300:300&image=/admin/uploads/زنجیر-فولادی-گالوانیزه--Galvanized-steel-chain-تجهیزات-صنعتی-ایران-ال-اکسپورت-107-u2553-55adba-unnamed (3).jpg&url=/admin/uploads/زنجیر-فولادی-گالوانیزه--Galvanized-steel-chain-تجهیزات-صنعتی-ایران-ال-اکسپورت-107-u2553-55adba-unnamed (3).jpg) | |

| Iranallexport | 021-55421083 |

| takinboksel |

| Iran |

| 021-55422784 |

Cold galvanized wire rope is plated with zinc at a temperature of approximately 240 degrees. At this temperature, a thin layer of zinc, which is about 18 microns, is placed on the surface of the cold galvanized towing wire. Of course, this thin layer is quickly lost in contact with metal surfaces and due to wear, and therefore cold galvanized wire rope often has little resistance to rust and is used in environments with low humidity. In most applications, surface greasing is done in order to increase the environmental capabilities of cold galvanized towing wire.

| |

| takinboksel | 021-55422784 |

| baradaranamir |

| Iran |

| 021-55406871 |

G80 chain actually specifies a grade of steel with a medium percentage of carbon, which is produced with the G80 grade. Dry chains have high tensile strength and good wear resistance and are used in lifting loads. g80 chains are produced in inch and millimeter sizes by hot forging method and are used in the production of chain slings. The general applications of galvanized dry chains can be mentioned on overhead cranes and in lever block connections and chain winches. The dry chain is packed as a barrel and is also used as six meters with a crooked hook.

| |

| baradaranamir | 021-55406871 |

| pichsazan |

| Iran |

| 021-55413167 |

The galvanized iron cap nut is produced from grades 4.6 and 5.6, both of which are very low carbon grades and are soft. Due to the malleability and easy use of galvanized iron cap nut, they are produced only with coarse ribs. The galvanized iron closed nut is used to cover the part of the iron screw that is outside the work surface. This type of screw does not require a washer and is used on hexagon, Allen and even machine screws. Galvanized iron cap nut in M5 size is widely used, but it is generally produced in M3 organic M24 mm sizes.

| |

| pichsazan | 021-55413167 |

| Dena-boxel |

| Iran |

| 021-55406871 |

Galvanized wire rope clip is produced in both steel grades and cast iron grades and in different sizes from 3 to 36 mm. In most cases, the wire rope clip is used in several series in parallel to have the restraining force necessary to keep two strands of tow wire on each other. The tow wire fastener is not considered as a replacement for the wire rope socket or press, and in comparison with them, it creates a lower tensile strength. However, for many uses, except for lifting the bar as a tow wire sling, the tow strap can be used.

| |

| Dena-boxel | 021-55406871 |

| pichsazan |

| Iran |

| 021-55413167 |

Galvanized iron nut size 10 is actually a standard nut type produced according to DIN934. The iron nut actually has a low percentage of carbon in its alloy composition, is malleable and is produced only with coarse ribs. Size 10 galvanized iron nut is used on hexagon screws, Allen screws and metric screws of size 10 mm and in iron grades 5.6 and 4.6. Two grades of galvanized iron beads can be found in the market, grades 4 and 5, both of which have low tensile strength and are used for relatively light industries.

| |

| pichsazan | 021-55413167 |

| kianbolt |

| Iran |

| 021-55401057 |

Flat washers are used in bolted connections and behind nuts. The flat washer is used as a support to prevent nut damage in the connection on the work piece and as a seat to increase the connection tension. The dry flat washer, which is used in dry bolt and nut connections, has a tensile strength of 800 N/mm2 and has heat hardening treatment. Dry flat washers are manufactured according to DIN125 standard and have a moderate percentage of carbon in the alloy structure.

| |

| kianbolt | 021-55401057 |

| takinboksel |

| Iran |

| 021-55422784 |

G80 galvanized chain is among the most practical lifting equipment along side of wire ropes. G80 chains are used on all kinds of manual chain blocks and electric hoists and are produced in various size. also in order to produce chain slings G80 chains are mostly used. as opposed to high tensile strength G80 chains have low resistance against corrosion and are therefore either electroplated as galvanized G80 chain or phosphate on the surface.

| |

| takinboksel | 021-55422784 |

| aflakiwire |

| Iran |

| 021-55425403 |

Anchor chain is a type of industrial chain that is designed specifically to be used on the ships and within marine industry. anchor chains are usually galvanized following hot dip galvanizing process to have better resistance against the corrosive sea water. there is a different between the lifting chains and anchor chains in design and anchor chains have an extra rod in the middle to refrain from engaging floating objects in the sea.

| aflakiwire | 021-55425403 |

| Iranallexport |

| Iran |

| 021-55421083 |

Steel wire ropes have two types of plating including hot galvanizing and cold galvanizing.

Hot deep galvanized wire is used in difficult and very rare cases due to its higher price than cold galvanized. it has a matte silver surface.

These steel wire ropes include different and upward grades of steel.

However, longer service life and very high resistance to rust and corrosion are their most important features compared to others.

| |

| Iranallexport | 021-55421083 |

| akhavan-wire-rope |

| Iran |

| 021-55411976 |

Iron chains produced by using and bending cut iron wires are often found in G30, G43 grades in the market. This iron chain is produced by cold forging method and after bending, it is welded at any point and to produce each grain of chain. Galvanized iron chain is used for purposes other than lifting loads, and low carbon steel alloy is used in its production, which has high hammerability and has a smooth surface.

| |

| akhavan-wire-rope | 021-55411976 |

| dracoboksel |

| Iran |

| 021-55409906 |

Eye bolt is produced in low iron grades, cast iron grades, and steel grades. In lifting bar, dynamo hook steel grades that are produced by hot forging method are often used. The dynamo hook is produced both in male form, which has a screw-shaped protrusion, and in female form, which has a threaded hole for connecting to the screw in lifting heavy industrial machinery.

| |

| dracoboksel | 021-55409906 |

| dracoboksel |

| Iran |

| 021-55409906 |

PC strand is produced as a single strand or single strand, and hence it is known as PC strand in English. The towing rope is often used in two main structures, 1X7 and 1X19, and has high diameter wires. Therefore, among all the various structures of the steel tow wire, the restraining tow wire has the least flexibility.

| |

| dracoboksel | 021-55409906 |

| Fathboxel |

| Iran |

| 02155411792- 02155405729 |

Galvanized tower crane non-rotating wire rope usually is manufactured of وhigh grades of alloy steel with high tensile strength. non rotating wire ropes are usually used in various diameters higher than 8 mm and mostly as 16 and 18 mm. structure of non-rotating wire rope is 19X7 and sometimes 35X7.

| |

| Fathboxel | 02155411792- 02155405729 |