- Steel Wire rope and accessories

- Machinery spare parts

- Industrial Tools & Parts

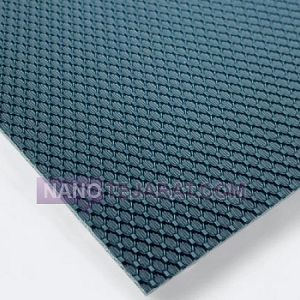

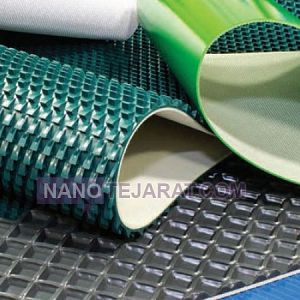

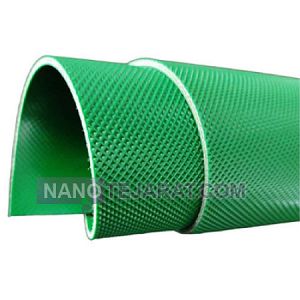

- 3 mm PVC Chess-Pattern Conveyor Belt(1)

- EM18/3 - 0+20 PVC petroleum AS 5.0 Optibelt conveyor belt(1)

- EX10/2 - 0+T24 PVC petroleum AS 2.5 Optibelt conveyor belt(1)

- polyurethane conveyor belt EM6/2 - 00+03(1)

- polyurethane conveyor belt model ER12/2 - 00+03(1)

- PVC conveyor belt model EM8/2 - 00+05(1)

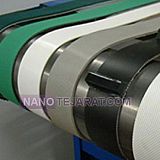

- Universal conveyor belt(1)

- Treadmill conveyor belt(1)

- 4 STAR conveyor belt(1)

- Rubber conveyor belt, 100 centimeters wide(1)

- 65-centimeter wide cleated rubber conveyor belt(1)

- 9 mm PVC Conveyor Belt with Polyester Backing(1)

- EM 10/2 - T18+07 PVC 3.2 Optibelt conveyor belt(1)

- EM10/2 - 0+T6 PVC petroleum AS 5.0 Optibelt conveyor belt(1)

- polyurethane conveyor belt EM6/2 - 00+02(1)

- polyurethane conveyor belt model EM8 - 00+S7(1)

- Polycord conveyor belt(1)

- Food conveyor belt(1)

- Polycord conveyor belt(1)

- 80-centimeter wide cleated rubber conveyor belt(1)

- Grip Conveyor Belt(1)

- EX10/2 - 0+T32 PVC petroleum AS Optibelt conveyor belt(1)

- EM10/2 - 0+T6 PVC AS 5.0 Optibelt conveyor belt(1)

- Polyurethane Conveyor Belt EM8/2 - 00+03(1)

- polyurethane conveyor belt model ER12 - 0+S10(1)

- Conveyor belt for use in snowy and cold areas(1)

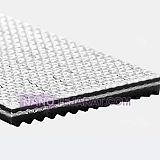

- Coated food grade polyurethane conveyor belt(1)

- Rubber conveyor belt, 65 centimeters wide(1)

- 100-centimeter wide cleated rubber conveyor belt(1)

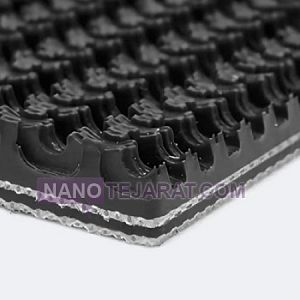

- 6 mm Double-Layer Rubber Grip Conveyor Belt(1)

- EX10/2-0+T32 PVC AS Optibelt conveyor belt(1)

- EX10/2 - 0+T32 PVC AS Optibelt conveyor belt(1)

- polyurethane conveyor belt model EM6/2 - 00+T21(1)

- PVC conveyor belt model EM10/2 - 00+07(1)

- EP Polyester Conveyor Belt(1)

- Food grade plastic conveyor belt(1)

- Rubber conveyor belt, 80 centimeters wide(1)

- Compressors

- Bearing and belt

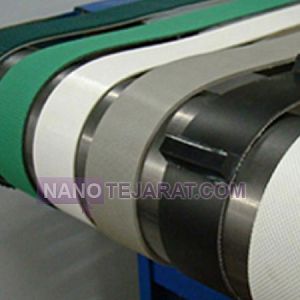

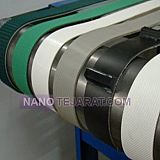

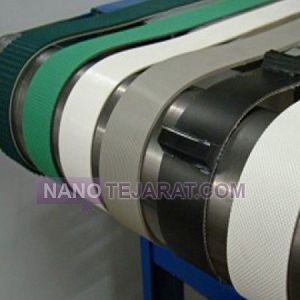

Conveyor Belt

Search Results For Conveyor Belt| power-belt |

| Iran |

| 021-22087856 |

Food grade plastic conveyor belt

The plastic food-grade conveyor belt is one of the most essential components in food industry transport systems, designed with specific technical features to enhance production line efficiency. These belts are typically made from polyethylene PE, polypropylene PP, or polyoxymethylene POM, offering high resistance to moisture, grease, mild chemicals, and temperature fluctuations. The surface of these belts is either smooth or textured to prevent food slippage and is designed for easy cleaning with disinfectants. Their temperature tolerance generally ranges from -40 to +90 degrees Celsius, making them suitable for both cold storage and baking line applications.

From a mechanical perspective, plastic food conveyor belts feature a modular or continuous design, allowing for easy installation, maintenance, and part replacement. These belts comply with international hygiene standards such as FDA and EU regulations, and are free from toxic materials that could pose risks during direct contact with food. With various widths and thicknesses available, and adjustable movement speeds, they are ideal for a wide range of applications including packaging, washing, sorting, and transporting food products. Additionally, their high resistance to wear and tear ensures a long service life, reduci

| |

| power-belt | 021-22087856 |

| sanatariya |

| Iran |

| 02133116613-33961181-3 |

4 star conveyor belt

The 4-star conveyor belt is among the most durable models designed for heavy-duty industrial applications under harsh operating conditions. This belt features a multilayer structure with four plies of polyester-nylon EP 125 to EP 250 fabric, cross-reinforced with abrasion-resistant rubber. The total thickness ranges from 8 to 14 millimeters, and the maximum allowable tensile strength reaches up to 1600 Newtons per millimeter of belt width. Its dry tensile strength is measured at up to 25 MPa, while in humid conditions it remains around 18 MPa. The top surface can be either smooth or patterned such as Chevron or Rough Top to prevent load slippage on inclined surfaces.

The operating temperature range for the 4-star conveyor belt spans from -30 to +120 degrees Celsius, with special models rated up to 150 degrees. This belt offers strong resistance to mineral oils, industrial grease, and surface abrasion from sharp particles. In abrasion loss testing according to ISO 4649, volume loss remains under 120 mm³. It supports continuous industrial use at speeds up to 4.5 meters per second. Common applications include mining operations, cement plants, power stations, and steel manufacturing industries. The bottom layer is typically made from tear-resistant and flame-retardant rubber comp

| |

| sanatariya | 02133116613-33961181-3 |

| sanatariya |

| Iran |

| 02133116613-33961181-3 |

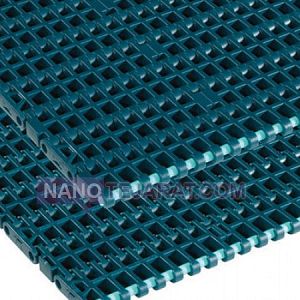

Conveyor belt

A conveyor belt is an industrial transfer component manufactured in variable widths ranging from 300 to 1600 millimeters and a total thickness of 8 to 15 millimeters. These belts typically consist of EP fabric layers with tensile strength between 125 and 315 newtons per millimeter. The multilayer polyester-nylon structure enhances flexibility and increases operational life under high-stress conditions. The top cover, with a thickness of 3 to 6 millimeters, is made from abrasion-resistant rubber and offers resistance to non-corrosive chemicals. Abrasion resistance is below 120 cubic millimeters according to DIN standards, and the operating temperature ranges from minus 30 to plus 90 degrees Celsius.

The conveyor belt can carry bulk loads up to 180 kilograms per meter at speeds between 1 and 4 meters per second. Its bending radius ranges from 300 to 600 millimeters depending on thickness. The surface hardness is typically between 60 and 70 Shore A, ensuring effective performance on industrial rollers. These belts are used in packaging lines, mining, steel production, agriculture, and food industries. They are designed for stable, long-term performance even under continuous operation in humid environments.

| |

| sanatariya | 02133116613-33961181-3 |

| power-belt |

| Iran |

| 021-22087856 |

4 STAR conveyor belt

The 4 STAR conveyor belt is a high-quality industrial belt designed for a wide range of applications in both light and heavy industries. Made from durable PVC or PU compounds, it features a multi-layered structure to enhance tensile strength and resistance to wear. The outer surface of the belt can be smooth, grooved, or textured, depending on the specific requirements of the application. These characteristics make the 4 STAR belt a reliable choice for transporting various materials, packages, components, and products under different environmental conditions.

Technically, the 4 STAR conveyor belt offers thermal resistance in the range of -10 to +80 degrees Celsius and is engineered to withstand exposure to oils, greases, moisture, and mild chemicals. Its high flexibility and capability to operate on curved or inclined conveyor systems add to its versatility. The belt can be manufactured in different thicknesses, colors, and widths to meet diverse industrial demands. With easy installation, low maintenance, and long service life, the 4 STAR conveyor belt finds widespread use in packaging, printing, textile, pharmaceutical, and food processing industries.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

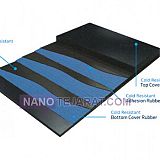

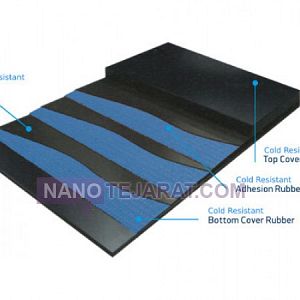

Conveyor belt for use in snowy and cold areas

The conveyor belt designed for snowy and cold regions is made from materials resistant to low temperatures and harsh environmental conditions to ensure stable and uninterrupted performance even at subzero temperatures. These belts are typically constructed from polyurethane or specialized rubber compounds with additives that prevent cracking and stiffness caused by cold, maintaining flexibility in freezing conditions. The belt surface is coated with anti-slip and wear-resistant layers to provide high traction on icy and snowy surfaces, enhancing safety and stability during material transport.

Structurally, these belts offer high resistance to abrasion and tearing, chemical resistance against de-icing agents and salts, and the ability to withstand mechanical stresses in tough environmental settings. Their design supports operation at varying speeds and long lengths while resisting freezing and corrosion. Using these belts in mining, transportation, and material processing industries in cold regions increases efficiency, reduces maintenance costs, and guarantees continuous conveyor system performance.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

polyurethane conveyor belt model ER12/2 - 00+03

The polyurethane conveyor belt model ER12/2 - 00+03 consists of two layers of reinforced polyester fabric with a tensile strength of 12 N/mm. Its top surface is made of transparent polyurethane with a 0.3 mm thickness, offering excellent resistance to abrasion, tearing, and industrial oils. The total belt thickness is approximately 3.0 mm, with a surface weight of about 3.1 kg/m². The surface friction coefficient is 0.65 in dry and 0.48 in wet conditions. This belt is designed for medium to heavy-duty conveying in food processing, packaging, and logistics industries.

The ER12/2 - 00+03 polyurethane belt operates reliably within a temperature range of -10°C to +100°C. The minimum recommended pulley diameter is 40 mm, making it suitable for robust conveying systems. Its bottom layer is engineered with low friction to ensure smooth, stable, and quiet operation. Tear resistance according to DIN 22102 is approximately 250 N/mm. This belt meets FDA and EU 10/2011 requirements for direct food contact and provides strong durability against moisture, repeated washing, and mild chemical exposure.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

polyurethane conveyor belt model EM6/2 - 00+T21

The polyurethane conveyor belt model EM6/2 - 00+T21 consists of two layers of polyester fabric with a tensile strength of 6 N/mm. Its top surface features a matte polyurethane coating with a 0.8 mm thickness, providing excellent resistance to abrasion, oils, and fats. The total belt thickness is approximately 2.6 mm with a surface weight of 2.3 kg/m². The friction coefficient is 0.55 in dry and 0.4 in wet conditions. This belt is engineered for high-precision conveying in food, pharmaceutical, and packaging industries, ensuring consistent performance at medium to high speeds.

The EM6/2 - 00+T21 polyurethane belt operates reliably within a temperature range of -15°C to +90°C. The minimum pulley diameter for optimal installation is 25 mm, making it suitable for compact systems. Its bottom layer is designed with low friction to guarantee smooth and silent movement. Tear resistance according to DIN 22102 is approximately 180 N/mm. This belt meets FDA requirements for direct food contact and provides strong resistance against moisture, mild chemicals, and repeated washing cycles.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

EP Polyester Conveyor Belt

The EP polyester conveyor belt is manufactured using high-quality polyester fibers in the tensile layers, providing exceptional resistance to tension and mechanical stresses. Its structure consists of two main layers: a polyester layer for tensile strength and a cotton or nylon fabric layer for flexibility and bending resistance. This combination ensures high durability against abrasion and tearing, allowing stable performance under harsh working conditions and heavy loads. Additionally, the belt surface is designed to provide adequate friction for material transfer and prevent slippage.

The structural features of the EP polyester belt include lightweight construction, uniform thickness, and the ability to withstand varying temperatures in industrial environments. It is resistant to common chemicals and moisture, making it suitable for conveying materials in mining, agriculture, and packaging industries. The belt’s flexibility reduces stress on rollers and motors, enhancing conveyor system efficiency, which results in lower maintenance costs and extended belt lifespan.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

EX10/2 - 0+T24 PVC petroleum AS 2.5 Optibelt conveyor belt

The EX10/2 - 0+T24 PVC petroleum AS 2.5 Optibelt conveyor belt is made of polyvinyl chloride with a thickness of 2.5 mm and heat resistance up to 90°C. Its standard width is 240 mm and it can carry loads up to 400 kg per meter. The internal EP fabric layer has a reinforced two-layer structure, providing tensile strength of 10 MPa and high mechanical durability. This belt is designed for transporting petroleum and its derivatives, offering significant chemical resistance against oil, grease, and hydrocarbons. The wear-resistant PVC surface and high flexibility increase the operational lifespan of the belt.

The belt has a smooth surface with controlled friction, optimized for operation between -20°C and +80°C. Its specific weight is 1.35 kg per square meter, with an estimated operational lifespan of 4 years. Tensile strength is 3500 N per 50 mm, with elongation under full load below 2%. The two-layer structure with PVC coating ensures uniform material transfer and easy installation. Crack resistance and quiet operation are key features of this industrial product.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

EM10/2 - 0+T6 PVC petroleum AS 5.0 Optibelt conveyor belt

The EM10/2 - 0+T6 PVC petroleum AS 5.0 Optibelt conveyor belt is made of polyvinyl chloride with a thickness of 5 mm and heat resistance up to 90°C. Its standard width is 60 mm and it can carry loads up to 200 kg per meter. The internal EP fabric layer has a reinforced two-layer structure, providing tensile strength of 10 MPa and high mechanical durability. This belt is designed for transporting petroleum and its derivatives, offering high chemical resistance against oil, grease, and hydrocarbons. The wear-resistant PVC surface and high flexibility increase the operational lifespan of the belt.

The belt has a smooth surface with controlled friction, optimized for operation between -20°C and +80°C. Its specific weight is 1.4 kg per square meter, with an estimated operational lifespan of 5 years. Tensile strength is 2000 N per 50 mm, with elongation under full load below 2%. The two-layer structure with PVC coating ensures uniform material transfer and easy installation. Crack resistance and quiet operation are key features of this industrial product.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

polyurethane conveyor belt model ER12 - 0+S10

The polyurethane conveyor belt model ER12 - 0+S10 is made of a reinforced polyester layer with a tensile strength of 12 N/mm. Its top surface consists of a soft polyurethane coating with a 1.0 mm thickness, providing high grip and effective impact absorption for heavy loads. The total belt thickness is approximately 3.2 mm, with a surface weight of 3.0 kg/m². The surface friction coefficient is 0.68 in dry and 0.5 in wet conditions. This belt is designed for heavy-duty conveying in food processing, packaging, and logistics industries, ensuring excellent mechanical stability.

The ER12 - 0+S10 polyurethane belt performs reliably in a temperature range from -15°C to +100°C. The minimum pulley diameter for proper installation is 40 mm. Its bottom surface is engineered with low friction to guarantee smooth and vibration-free movement. Tear resistance according to DIN 22102 is approximately 250 N/mm. This model complies with FDA and EU 10/2011 standards for direct food contact and provides excellent resistance to moisture, fats, and industrial cleaning agents.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

EX10/2 - 0+T32 PVC petroleum AS Optibelt conveyor belt

The EX10/2 - 0+T32 PVC petroleum AS Optibelt conveyor belt is made of polyvinyl chloride with a thickness of 4 mm and heat resistance up to 90°C. Its standard width is 320 mm and it can carry loads up to 600 kg per meter. The internal EP fabric layer has a reinforced two-layer structure, providing tensile strength of 10 MPa and high mechanical durability. This belt is designed for transporting petroleum and its derivatives, offering high chemical resistance against oil, grease, and hydrocarbons. The wear-resistant PVC surface and high flexibility increase the operational lifespan of the belt.

The belt has a smooth surface with controlled friction, optimized for operation between -20°C and +80°C. Its specific weight is 1.45 kg per square meter, with an estimated operational lifespan of 5 years. Tensile strength is 5000 N per 50 mm, with elongation under full load below 2%. The two-layer structure with PVC coating ensures uniform material transfer and easy installation. Crack resistance and quiet operation are key features of this industrial product.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

EM10/2 - 0+T6 PVC AS 5.0 Optibelt conveyor belt

The EM10/2 - 0+T6 PVC AS 5.0 Optibelt conveyor belt is made of polyvinyl chloride with a thickness of 5 mm and heat resistance up to 90°C. Its standard width is 60 mm and it can carry loads up to 200 kg per meter. The internal EP fabric layer has a reinforced two-layer structure, providing tensile strength of 10 MPa and high mechanical durability. This belt is designed for transporting dry and petroleum materials, offering significant chemical resistance against oil, grease, and hydrocarbons. The wear-resistant PVC surface and high flexibility increase the operational lifespan of the belt.

The belt has a smooth surface with controlled friction, optimized for operation between -20°C and +80°C. Its specific weight is 1.4 kg per square meter, with an estimated operational lifespan of 5 years. Tensile strength is 2000 N per 50 mm, with elongation under full load below 2%. The two-layer structure with PVC coating ensures uniform material transfer and easy installation. Crack resistance and quiet operation are key features of this industrial product.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

EX10/2 - 0+T32 PVC AS Optibelt conveyor belt

The EX10/2 - 0+T32 PVC AS Optibelt conveyor belt is made of polyvinyl chloride with a thickness of 4 mm and heat resistance up to 90°C. Its standard width is 320 mm and it can carry loads up to 550 kg per meter. The internal EP fabric layer has a reinforced two-layer structure, providing tensile strength of 10 MPa and high mechanical durability. This belt is designed for transporting dry and semi-liquid materials, offering adequate chemical resistance against oil and grease. The wear-resistant PVC surface and high flexibility increase operational lifespan and ensure quiet operation.

The belt has a smooth surface with controlled friction, optimized for operation between -20°C and +80°C. Its specific weight is 1.45 kg per square meter, with an estimated operational lifespan of 5 years. Tensile strength is 5000 N per 50 mm, with elongation under full load below 2%. The two-layer structure with PVC coating ensures uniform material transfer and easy installation. Crack resistance and corner flexibility are key features of this industrial belt.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

EX10/2-0+T32 PVC AS Optibelt conveyor belt

The EX10/2-0+T32 PVC AS Optibelt conveyor belt is made of polyvinyl chloride with a thickness of 4 mm and heat resistance up to 90°C. Its standard width is 320 mm and it can carry loads up to 550 kg per meter. The internal EP fabric layer has a reinforced two-layer structure, providing tensile strength of 10 MPa and high mechanical durability. This belt is suitable for transporting dry and semi-liquid materials and offers excellent chemical resistance against oil and grease. The wear-resistant PVC surface and high flexibility increase operational lifespan and ensure quiet performance.

The belt has a smooth surface with controlled friction, optimized for operation between -20°C and +80°C. Its specific weight is 1.45 kg per square meter, with an estimated operational lifespan of 5 years. Tensile strength is 5000 N per 50 mm, with elongation under full load below 2%. The two-layer structure with PVC coating ensures uniform material transfer and easy installation. Crack resistance and corner flexibility are key features of this industrial belt.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Polycord conveyor belt

The polycord conveyor belt is made of thermoplastic polyurethane with a surface hardness between 85 and 95 Shore A, suitable for conveying light to medium-weight materials. The belt diameter typically ranges from 3 to 15 millimeters, with a tensile strength between 40 and 70 megapascals. These belts can operate within a temperature range of -20 to +80 degrees Celsius and offer resistance to abrasion, light oils, and some mild chemicals. The belt is designed for thermal welding and quick onsite joining, reducing system downtime.

The structure of the polycord conveyor belt usually includes a reinforcing fiber core that enhances tensile strength and dimensional stability. Optimal initial tension during installation is recommended between 5% and 8% of the belt length to prevent slippage. The belt’s linear speed can reach up to 25 meters per second in industrial applications, and its high flexibility ensures quiet operation. This belt is ideal for packaging lines, assembly systems, light conveyor belts, and industrial automation equipment.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

EM 10/2 - T18+07 PVC 3.2 Optibelt conveyor belt

The EM 10/2 - T18+07 PVC 3.2 Optibelt conveyor belt is made of polyvinyl chloride with a thickness of 3.2 mm and heat resistance up to 80°C. Its standard width is 180 mm, capable of carrying loads up to 300 kg per meter. The internal EP fabric layer has a reinforced two-layer structure, providing tensile strength of 10 MPa and high mechanical durability. This belt is designed for transporting materials with moderate chemical resistance, such as oil and light petroleum products. The wear-resistant PVC surface and high flexibility increase belt lifespan and ensure quiet operation.

The belt has controlled friction and is optimized for operation between -15°C and +70°C. Its specific weight is 1.3 kg per square meter, with an estimated operational lifespan of 4 years. Tensile resistance is 2500 N per 50 mm, and elongation under full load is below 2.5%. The two-layer structure with PVC coating guarantees uniform material transfer and easy installation. Crack resistance and flexibility at corners are key features of this industrial belt.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

100-centimeter wide cleated rubber conveyor belt

The 100-centimeter wide cleated rubber conveyor belt is designed with a 15-millimeter thickness and a standard length of 30 meters, capable of handling up to 1000 kilograms per meter. Its internal structure includes multiple layers of reinforced polyester and a cleated rubber cover with high abrasion resistance. The recommended maximum operating speed is 3 meters per second, with an operational temperature range of -30 to 95 degrees Celsius. This belt is resistant to oil, water, and light to semi-heavy chemicals, making it suitable for heavy mining, steel industries, and large packaging lines.

The cleated top layer has a minimum tensile strength of 22 MPa and a friction coefficient of 0.75 to ensure safe and stable material transfer. Rolls feature a 60-millimeter inner diameter and weigh approximately 95 kilograms. Installation is straightforward on drums and pulleys with a minimum radius of 250 millimeters. Factors such as incline angle, environmental conditions, material type, and ISO 21181 standards must be considered when purchasing.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

80-centimeter wide cleated rubber conveyor belt

The 80-centimeter wide cleated rubber conveyor belt is designed with a 12-millimeter thickness and a standard length of 25 meters, capable of handling up to 750 kilograms per meter. Its internal structure includes multiple layers of reinforced polyester and a cleated rubber cover with high abrasion resistance. The recommended maximum operating speed is 2.5 meters per second, with an operational temperature range of -25 to 90 degrees Celsius. This belt is resistant to oil, water, and light to semi-heavy chemicals, making it suitable for packaging lines, medium-duty mining, and heavy industries.

The cleated top layer has a minimum tensile strength of 18 MPa and a friction coefficient of 0.7 to ensure safe and stable material transfer. Rolls feature a 50-millimeter inner diameter and weigh approximately 65 kilograms. Installation is straightforward on drums and pulleys with a minimum radius of 220 millimeters. Factors such as incline angle, environmental conditions, material type, and ISO 21181 standards must be considered when purchasing.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Coated food grade polyurethane conveyor belt

The coated polyurethane food conveyor belt is specially engineered using hygienic polymer materials combined with a durable coating layer to ensure safe, fast, and contamination-free food transfer. This belt features a smooth, uniform, and non-porous surface that resists the absorption of moisture, grease, and food particles, effectively preventing the growth of microorganisms. The polyurethane composition offers excellent resistance to abrasion, tearing, and temperature variations, making it ideal for continuous operation in food production lines.

The coated layer enhances the belts chemical and mechanical resistance, protecting it from damage caused by cleaning agents, acids, and mechanical stress during food movement. Its flexible design ensures smooth operation across the conveyor system, while its lightweight structure and easy installation help reduce maintenance and repair costs over time. This belt is an ideal choice for dairy factories, meat processing plants, confectionery production, and other food processing environments.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

polyurethane conveyor belt model EM8 - 00+S7

The polyurethane conveyor belt model EM8 - 00+S7 is made of a single layer of polyester fabric with a tensile strength of 8 N/mm. Its top surface features a soft polyurethane coating with a thickness of 0.7 mm, providing high grip for precise transport of light and delicate products. The total belt thickness is approximately 2.1 mm, with a surface weight of around 1.9 kg/m². The friction coefficient is 0.65 in dry and 0.5 in wet conditions. This belt is ideal for packaging lines, carton conveying, and food or pharmaceutical applications.

The EM8 - 00+S7 polyurethane belt operates reliably within a temperature range of -10°C to +80°C. The minimum pulley diameter for proper installation is 30 mm. Its bottom surface is engineered with low friction to ensure smooth and silent operation at higher speeds. Tear resistance according to DIN 22102 is approximately 200 N/mm. This model is FDA-compliant for direct food contact and offers excellent resistance to moisture and oils, making it ideal for hygienic conveying environments.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Polycord conveyor belt

The Polycord conveyor belt is manufactured using advanced technology and high-quality raw materials to ensure excellent durability and performance in material handling across various industries. These belts feature a reinforced polyester or nylon core that provides high tensile strength and resistance to repeated bending. The outer rubber cover is designed to resist abrasion, heat, and chemicals, which enhances the belt’s lifespan and maintains reliable operation under diverse environmental conditions.

With an integrated and flexible structure, this product performs efficiently at different speeds and heavy loads, making it suitable for industrial conveyor lines, mining, and manufacturing plants. The high resistance to wear, tearing, and tension, combined with dimensional stability, ensures smooth and slip-free material transfer, preventing unexpected failures. Additionally, its compatibility with various conveyor systems makes the Polycord belt an ideal choice for improving productivity and reducing maintenance costs.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

6 mm Double-Layer Rubber Grip Conveyor Belt

The 6 mm double-layer rubber grip conveyor belt is made of two layers of durable rubber reinforced with polyester fabric, providing high tensile strength. The total thickness of 6 millimeters and the textured upper surface design increase friction and prevent load slippage. The tensile strength of this belt is approximately 250 to 400 newtons per millimeter, enabling it to carry medium to heavy loads. The double-layer structure ensures dimensional stability and extends service life in production lines with continuous operation.

The 6 mm double-layer rubber grip conveyor belt can operate within a temperature range of minus 20 to plus 90 degrees Celsius and is resistant to abrasion and impact. The deep grip patterns increase the friction coefficient up to about 0.8, allowing usage on inclines up to 25 degrees. Its good flexibility permits installation on pulleys with a minimum diameter of 100 millimeters. These features make it suitable for mining industries, heavy packaging applications, and transporting metallic components.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

polyurethane conveyor belt EM6/2 - 00+03

The polyurethane conveyor belt EM6/2 - 00+03 is composed of two layers of balanced-weave polyester fabric with a transparent polyurethane coating. The total belt thickness is approximately 1.6 mm, and the specific weight is about 1.3 kg per square meter. The allowable tensile force is 6 N per millimeter of belt width, providing excellent resistance to tearing and abrasion. The surface friction coefficient is 0.3 in dry contact and 0.25 in wet conditions. Its working temperature range is between -10 and +80 degrees Celsius, and it offers good resistance to oils and mild chemicals.

The top surface of the EM6/2 - 00+03 belt is smooth and non-adhesive, ensuring stable product transfer. The minimum pulley diameter for this belt is around 30 mm, and its antistatic properties comply with ISO 21178 standards. Due to its high flexibility and dimensional stability, it is suitable for food processing, packaging, and pharmaceutical applications. Its high wear resistance extends operational lifespan and reduces maintenance frequency.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

EM18/3 - 0+20 PVC petroleum AS 5.0 Optibelt conveyor belt

The EM18/3 - 0+20 PVC petroleum AS 5.0 Optibelt conveyor belt is made of polyvinyl chloride with a heat resistance of 90°C and can carry loads up to 500 kg per meter. Its total thickness is 5 mm with a standard width of 200 mm, offering high flexibility and superior abrasion resistance. The internal EP fabric layer has a reinforced three-layer structure, ensuring mechanical durability and tensile strength of 18 MPa. This belt is designed for transporting petroleum and its derivatives, providing high chemical resistance against oils and grease.

The belt has a smooth surface with controlled friction, optimized for operation between -20°C and +80°C. Its specific weight is 1.4 kg per square meter, and standard operational lifespan is estimated at 5 years. Tensile resistance is 4500 N per 50 mm, with elongation under full load below 2%. The three-layer structure and PVC coating guarantee quiet operation and uniform material transfer. Easy installation and crack resistance are key features of this industrial product.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Universal conveyor belt

The universal conveyor belt is a key component in material handling systems, designed to carry various types of loads across different industries with durability and stable performance. These belts are constructed from multiple layers that resist tension, abrasion, and tearing, and their continuous, seamless structure ensures uniform load transfer without slippage. The raw materials used typically include reinforced polymers, providing protection against harsh environmental conditions such as temperature variations, moisture, and exposure to chemicals.

Another important feature of the universal conveyor belt is its high flexibility and resistance to repeated bending, allowing it to be used in conveyor systems with complex routes and multiple angles. These belts are produced in various widths and thicknesses and can handle heavy loads at variable speeds. Additionally, the belt surface is designed to provide the necessary grip to prevent load slippage, ensuring efficient transfer with minimal maintenance and downtime.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Polyurethane Conveyor Belt EM8/2 - 00+03

The polyurethane conveyor belt model EM8/2 - 00+03 consists of two layers of polyester fabric with a tensile strength of 8 N/mm. Its top cover is made of transparent polyurethane with a 0.3 mm thickness, providing excellent resistance to abrasion and oils. The total belt thickness is approximately 2.3 mm, with a surface weight of around 2.1 kg/m². The surface friction coefficient measures 0.6 in dry and 0.45 in wet conditions. This belt is ideal for precise conveying in packaging, pharmaceutical, and food processing industries.

The operating temperature range of the polyurethane conveyor belt EM8/2 - 00+03 is from -10°C to +80°C. The minimum pulley diameter is 30 mm, allowing use with compact drive systems. The bottom layer features low friction for smooth and silent operation. Tear resistance according to DIN 22102 is approximately 200 N/mm. This model is manufactured in compliance with FDA requirements for direct food contact and maintains stability against moisture and frequent cleaning cycles.

| |

| power-belt | 021-22087856 |

| Roll-pars-belt-bearing |

| Iran |

| 09126482568 |

Pirelli conveyor belt

Pirelli conveyor belts, manufactured in Italy, are widely used in heavy industries due to their high engineering quality and reinforced rubber compounds. The internal structure typically includes EP reinforcement layers with tensile strength ranging from 800 to 2000 N/mm. These belts have an overall thickness between 10 to 25 mm, and their top cover is made of abrasion-resistant rubber with a hardness of 65 to 70 Shore A. Pirelli uses a vulcanization system to bond the layers, providing excellent adhesion and resistance to localized tearing.

The belts are produced in standard widths from 500 to 1600 mm and are available in profiled versions for moderate to steep incline applications. Thermal resistance ranges from -25°C to +130°C, while heat-resistant models can withstand up to 300°C. Oil-resistant and chemically resistant versions are also offered, suitable for corrosive and humid environments. The service life of these conveyor belts is reported to be up to 50% longer than the industry average.

| |

| Roll-pars-belt-bearing | 09126482568 |

| power-belt |

| Iran |

| 021-22087856 |

polyurethane conveyor belt EM6/2 - 00+02

The polyurethane conveyor belt EM6/2 - 00+02 is constructed from two layers of high-density polyester fabric coated with transparent polyurethane. The total thickness is approximately 1.4 mm, and the specific weight is around 1.25 kg per square meter. The permissible tensile strength is 6 N per millimeter of belt width, providing excellent mechanical stability. The top surface is plain, with a friction coefficient of 0.3 in dry and 0.28 in wet conditions. The working temperature range is between -10 and +80 degrees Celsius, and it offers good resistance to light oils and diluted chemicals.

The EM6/2 - 00+02 belt features a smooth, flexible top surface that ensures consistent product movement on production lines. The minimum pulley diameter is approximately 25 mm. Its antistatic property is certified according to ISO 21178. This belt is ideal for food, pharmaceutical, and packaging industries that require hygienic and non-stick surfaces. Long service life and easy maintenance are among its key advantages.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Rubber conveyor belt, 65 centimeters wide

The 65-centimeter wide rubber conveyor belt is designed with an 8-millimeter thickness and a standard length of 20 meters, capable of handling up to 500 kilograms per meter. Its structure includes internal layers of reinforced polyester and a durable rubber cover, providing high abrasion and tensile resistance. The recommended maximum operating speed is 2 meters per second, with an operational temperature range of -20 to 80 degrees Celsius. This belt is resistant to oil, water, and light chemicals, making it suitable for packaging lines, mining, and food industries.

The top layer of the belt has a minimum tensile strength of 15 MPa and a friction coefficient of 0.6 to ensure safe material transfer. Rolls feature a 50-millimeter inner diameter and weigh approximately 45 kilograms. Installation is straightforward on drums and pulleys with a minimum radius of 200 millimeters. Factors such as incline angle, environmental conditions, material type, and ISO 21181 standards must be considered when purchasing.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

PVC conveyor belt model EM8/2 - 00+05

The PVC conveyor belt model EM8/2 - 00+05 consists of two layers of polyester fabric with a tensile strength of 8 N/mm. Its top surface is made of smooth PVC with a 0.5 mm thickness, providing excellent resistance to abrasion, moisture, and contamination. The total belt thickness is approximately 2.5 mm, with a surface weight of around 2.9 kg/m². The surface friction coefficient is 0.55 in dry and 0.4 in wet conditions. This belt is suitable for conveying light to medium-weight products in dry food, packaging, and assembly industries.

The EM8/2 - 00+05 PVC belt performs reliably in a temperature range from -10°C to +80°C. The minimum pulley diameter for efficient installation is 30 mm. Its bottom layer is designed with low friction to ensure smooth, quiet, and stable operation. Tear resistance according to DIN 22102 is approximately 200 N/mm. This model is resistant to moisture, light oils, and industrial detergents, making it ideal for continuous conveying systems operating at medium speeds.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Rubber conveyor belt, 100 centimeters wide

The 100-centimeter wide rubber conveyor belt is designed with a 12-millimeter thickness and a standard length of 30 meters, capable of handling up to 900 kilograms per meter. Its structure includes multiple layers of reinforced polyester and a durable rubber cover with high abrasion resistance. The recommended maximum operating speed is 3 meters per second, with an operational temperature range of -30 to 95 degrees Celsius. This belt is resistant to oil, water, and light to semi-heavy chemicals, making it suitable for mining, heavy industries, and packaging lines.

The top layer of the belt has a minimum tensile strength of 20 MPa and a friction coefficient of 0.7 to ensure safe material transfer. Rolls feature a 60-millimeter inner diameter and weigh approximately 85 kilograms. Installation is straightforward on drums and pulleys with a minimum radius of 250 millimeters. Factors such as incline angle, environmental conditions, material type, and ISO 21181 standards must be considered when purchasing.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

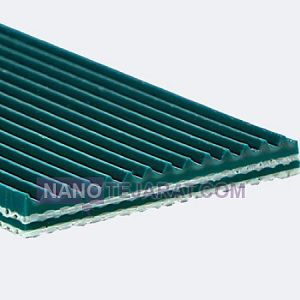

PVC conveyor belt model EM10/2 - 00+07

The PVC conveyor belt model EM10/2 - 00+07 consists of two layers of polyester fabric with a tensile strength of 10 N/mm. Its top surface is made of a green PVC coating with a thickness of 0.7 mm, offering excellent resistance to abrasion, moisture, and grease. The total belt thickness is approximately 2.8 mm, with a surface weight of around 3.2 kg/m². The friction coefficient is 0.6 in dry and 0.45 in wet conditions. This belt is suitable for conveying packaged goods, industrial parts, and medium-weight products on production lines.

The EM10/2 - 00+07 PVC belt operates reliably within a temperature range of -10°C to +80°C. The minimum pulley diameter for efficient installation is 40 mm. Its bottom layer features low friction for smooth, uniform, and silent movement. Tear resistance according to DIN 22102 is approximately 220 N/mm. This model is resistant to light oils, humidity, and cleaning agents, making it an optimal choice for packaging, assembly, printing, and dry food industries.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

9 mm PVC Conveyor Belt with Polyester Backing

The 9 mm PVC Conveyor Belt with Polyester Backing is manufactured from polyvinyl chloride combined with a polyester reinforcement layer, providing very high tensile strength. The 9 millimeter thickness allows the belt to withstand heavy loads up to approximately 2500 newtons per millimeter. The PVC top layer offers anti-slip properties and abrasion resistance, while the polyester backing ensures dimensional stability and high flexibility. This structure makes the belt suitable for material handling in heavy and semi-heavy duty production lines.

The 9 mm PVC conveyor belt with polyester backing operates reliably within a temperature range of minus 15 to plus 90 degrees Celsius and resists moisture and oil. Its multilayer design enables usage on pulleys with a minimum diameter of 120 millimeters without cracking or deformation. Due to its long service life and high strength, this belt is considered a reliable choice for steel industries, mining operations, and heavy packaging material transport.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

65-centimeter wide cleated rubber conveyor belt

The 65-centimeter wide rubber conveyor belt with cleats is designed with a 10-millimeter thickness and a standard length of 20 meters, capable of handling up to 550 kilograms per meter. Its structure includes reinforced polyester internal layers and a high-abrasion cleated rubber cover. The recommended maximum operating speed is 2 meters per second, with an operational temperature range of -20 to 85 degrees Celsius. This belt is resistant to oil, water, and light chemicals, making it suitable for packaging lines, light mining, and food industries.

The cleated top layer has a minimum tensile strength of 16 MPa and a friction coefficient of 0.7 to ensure stable and safe material transfer. Rolls feature a 50-millimeter inner diameter and weigh approximately 50 kilograms. Installation is straightforward on drums and pulleys with a minimum radius of 200 millimeters. Factors such as incline angle, environmental conditions, material type, and ISO 21181 standards must be considered when purchasing.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Rubber conveyor belt, 80 centimeters wide

The 80-centimeter wide rubber conveyor belt is designed with a 10-millimeter thickness and a standard length of 25 meters, capable of handling up to 700 kilograms per meter. Its structure includes internal layers of reinforced polyester and a durable rubber cover with high abrasion resistance. The recommended maximum operating speed is 2.5 meters per second, with an operational temperature range of -25 to 90 degrees Celsius. This belt is resistant to oil, water, and light chemicals, making it suitable for packaging lines, mining, and heavy industries.

The top layer of the belt has a minimum tensile strength of 18 MPa and a friction coefficient of 0.65 to ensure safe material transfer. Rolls feature a 50-millimeter inner diameter and weigh approximately 60 kilograms. Installation is straightforward on drums and pulleys with a minimum radius of 220 millimeters. Factors such as incline angle, environmental conditions, material type, and ISO 21181 standards must be considered when purchasing.

| |

| power-belt | 021-22087856 |

| ebtekarsanat |

| Iran |

| 021-33990391 |

PU Conveyor belt

A conveyor belt is a key component in material handling systems, consisting of reinforcing layers and a rubber or polymer top cover. The internal plies are typically made of EP polyester-polyamide or NN nylon-nylon fabric with tensile strengths ranging from 1000 to 2000 N/mm. The total belt thickness varies between 8 and 25 mm depending on the load type and conveying distance. The top cover is made from abrasion-resistant rubber with a hardness of 60 to 70 Shore A, designed to withstand sharp and abrasive materials.

These belts are manufactured in widths from 400 to 2000 mm and in customized lengths based on industrial requirements. The operating temperature range is from -25°C to +130°C, while heat-resistant models can tolerate up to 300°C. Oil-resistant, acid-resistant, and wear-resistant variants are also available to suit harsh environments. Chevron or sidewall conveyor belts are commonly used for steep-angle conveying to prevent slippage and improve load stability.

| |

| ebtekarsanat | 021-33990391 |

| Roll-pars-belt-bearing |

| Iran |

| 09126482568 |

Cement conveyor belt

In the cement industry, the conveyor belt must withstand heavy loads, intense abrasion, and dusty environments. Cement plant conveyor belts are typically made from reinforced EP polyester-polyamide or NN nylon-nylon fabric layers. These fabrics provide high tensile strength, ranging from 200 to 2000 N/mm. Belt thickness varies from 8 to 25 mm depending on installation requirements. The outer surface is coated with abrasion-resistant rubber, with Shore A hardness between 60 and 70, ensuring long service life.

These belts are commonly manufactured in widths from 500 to 1600 mm and can withstand operating temperatures between -20°C and +120°C. For areas exposed to clinker or hot materials, heat-resistant belts are used, capable of withstanding up to 300°C. The top rubber cover is usually 4 to 8 mm thick to protect against abrasive particles. For inclined conveying, the use of profiled surfaces or reinforced cleats allows for stable and efficient transport on steep slopes.

| |

| Roll-pars-belt-bearing | 09126482568 |

| power-belt |

| Iran |

| 021-22087856 |

Treadmill conveyor belt

The treadmill conveyor belt is specially designed and made from high-quality materials to provide excellent resistance to abrasion, tension, and heat. It features a multi-layer structure, typically with a tensile-resistant fiber core and a durable, non-slip surface layer to ensure smooth and safe user movement. Additionally, the belt’s thickness and flexibility are optimized to reduce the load on the treadmill motor and extend the machine’s lifespan.

The structural features of the treadmill conveyor belt include high resistance to moisture, body sweat, and environmental temperature changes, ensuring stable and long-lasting performance under various conditions. The belt is also engineered to maintain appropriate friction with the motor and the underlying surface, reducing energy consumption and minimizing maintenance needs. These characteristics make the treadmill conveyor belt ideal for use in gyms, sports centers, and professional environments.

| |

| power-belt | 021-22087856 |

| Roll-pars-belt-bearing |

| Iran |

| 09126482568 |

Plaster mine conveyor belt

The gypsum mine conveyor belt must be made of wear-resistant and corrosion-resistant materials due to the harsh working conditions. Its internal structure typically includes reinforced EP fabric layers with tensile strength between 1200 and 1800 N/mm. The total belt thickness ranges from 10 to 20 mm to withstand heavy loads and provide adequate tear resistance. The belt’s top cover is made of rubber with a hardness of 65 to 70 Shore A, offering high resistance to abrasion and mineral impact.

The conveyor belt width usually varies between 600 and 1500 mm and can be customized according to specific applications. These belts operate efficiently in temperatures ranging from -20°C to +120°C, with some models tolerating up to 250°C heat resistance. Chemical resistance against gypsum dust and corrosive substances is also a critical feature. These technical characteristics enhance service life and reduce maintenance costs in gypsum mining environments.

| |

| Roll-pars-belt-bearing | 09126482568 |

| power-belt |

| Iran |

| 021-22087856 |

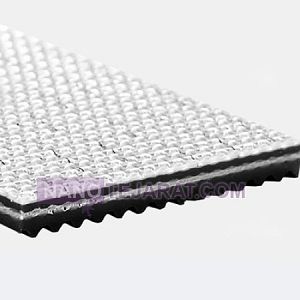

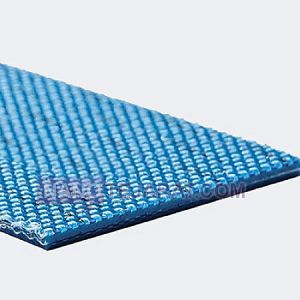

3 mm PVC Chess-Pattern Conveyor Belt

The PVC chess-pattern conveyor belt is manufactured from reinforced polyvinyl chloride layers with a typical thickness of 3 to 5 millimeters. The raised chess-pattern surface with a height of 1 to 2 millimeters is designed to provide high friction and prevent load slippage. The density of layers and the internal fabric weave deliver tensile strength of approximately 200 to 400 newtons per millimeter. These characteristics enable stable load transfer in packaging and assembly industries.

The PVC chess-pattern conveyor belt operates in a temperature range from minus 10 to plus 80 degrees Celsius and offers resistance to oil, moisture, and abrasion. The textured surface design ensures uniform pressure distribution and extends the service life of the belt. High flex resistance allows usage on pulleys with a minimum diameter of 60 millimeters. These specifications make the belt widely applicable in food industries, logistics, and automated production lines.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Food conveyor belt

The food conveyor belt is designed using hygienic materials that comply with international standards to ensure product safety and quality throughout the transfer process. It is made from abrasion-resistant, moisture-resistant, and temperature-tolerant materials free from toxic substances, preventing contamination of food products. Additionally, the belt’s smooth and seamless surface facilitates easy cleaning and quick disinfection, which is essential for food industry applications.

Structurally, the food conveyor belt features high flexibility and adequate resistance to tearing and tension, allowing continuous and uninterrupted material transfer. It is also resistant to common chemicals used in washing and sanitizing processes, making it suitable for packaging lines, fresh product handling, and various stages of food production. Its optimized design helps reduce machine energy consumption and extends the belt’s service life.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

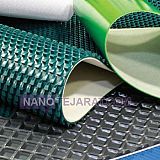

Grip Conveyor Belt

The grip conveyor belt is manufactured from PVC or PU reinforced with a polyester fabric layer, and its top surface features a grip coating with a thickness of 2 to 4 millimeters. This textured or ribbed layer increases the friction coefficient up to about 0.7 and prevents load slippage on inclines up to 20 degrees. The tensile strength of the belt typically ranges between 200 and 400 newtons per millimeter, enabling it to handle medium to semi-heavy loads effectively.

The grip conveyor belt operates reliably within a temperature range of minus 10 to plus 80 degrees Celsius and is resistant to moisture and abrasion. Its flexibility allows installation on pulleys with a minimum diameter of 80 millimeters without cracking or deformation. Due to its high grip and safe load transfer capability, this belt is widely used in food processing, carton manufacturing, packaging systems, and the handling of delicate components.

| |

| power-belt | 021-22087856 |

| yeekta-bearings |

| Iran |

| 021-33925513 |

60 cm industrial conveyor belt

The 60-centimeter industrial conveyor belt is designed with an effective width of 600 millimeters and a total thickness ranging from 9 to 12 millimeters. It is made of reinforced rubber with EP fabric layers providing tensile strength between 160 and 250 newtons per millimeter. The four-layer polyester-nylon composition enhances resistance to stretching and tearing. The top cover layer is approximately 4 millimeters thick, while the bottom layer is about 2 millimeters. Its abrasion resistance is less than 130 cubic millimeters and it can operate in a temperature range from minus 25 to plus 80 degrees Celsius.

| |

| yeekta-bearings | 021-33925513 |