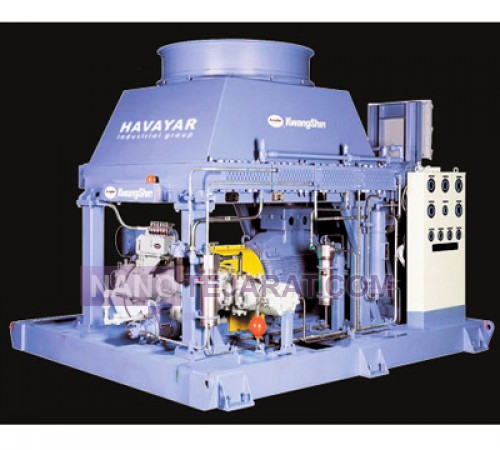

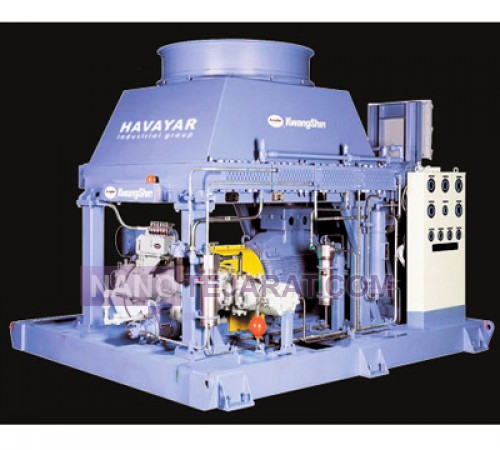

compressor , Iran

A compressor is a mechanical device that increases the pressure of compressible fluids like air. It converts mechanical energy into potential pressure energy. Compressors are mainly categorized into positive displacement e.g., piston, screw and dynamic e.g., centrifugal types. Output pressure can range from a few bar to hundreds of bar. Its volumetric flow rate can be designed from under 100 to over 50,000 liters per minute. Energy efficiency is a key parameter in selecting this equipment. Modern compressors feature intelligent control systems for consumption optimization.

The general structure includes a drive motor, compression unit, cooling system, and control equipment. Three-phase electric motors with IE3 or IE4 efficiency standards are the most common drivers. In large models, the cooling system can be water-cooled or air-cooled. Inlet filters with 99.9% efficiency prevent particle entry into the compression chamber. An air receiver tank stabilizes system pressure and reduces pulsations. This equipment is critical in industries like automotive, food, pharmaceutical, and mining. Regular scheduled maintenance based on operating hours is essential for reliable performance.You can order and buy compressor from Iran by contacting us through whatsaap and email.

WEBSITE: compressor Iran

How to Test Compressor Health

To test compressor health, first disconnect the devices power and depressurize the system. Measure the resistance of the windings Start, Run, Common with an ohmmeter. The values must match the manufacturers datasheet, and there should be no short circuit or open circuit between any two terminals. Check for insulation faults with a megohmmeter between the windings and the body. Resistance should be above 1 megohm. Test mechanical operation by manually rotating the shaft and listening for free pulley noise. During startup, measure the starting and running current with a clamp ammeter and compare it with the rated value. The compressor operating temperature should not exceed the permissible limit typically 70-90°C. The presence of abnormal sounds like knocking or grinding indicates internal wear. Finally, perform an oil and gas leak test with a detector.

Oil Free Equipments

compressor

compressor

Portable Compressors

Industrial compressor

Centrifugal Compressor Integrally Gear

High Pressure Equipments

Turbo Compressors

dryer