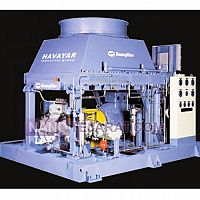

compressor , Iran

- Price :To negotiate

- order by whatsapp

A reciprocating compressor compresses air using the linear motion of a piston within a cylinder. These compressors are built in single or multi-cylinder configurations with V, L, or inline arrangements. Their output pressure can range from 8 bar in standard models to 500 bar in ultra-high-pressure models. Air flow typically varies between 10 and 5000 liters per minute. Piston rings are made of carbon or Teflon to reduce friction and wear. A forced lubrication system with a dedicated pump manages temperature and component lifespan. The crankshaft is forged steel with heat treatment to withstand shock loads.

The compressor structure includes automatic spring-loaded valves made of steel with microsecond response. Cylinder heads are often aluminum alloy or cast iron with cooling passages. Air or water cooling systems maintain operating temperatures between 70-90°C. The compression ratio per stage is typically limited to 3-4, with multiple stages used for higher pressures. Anti-wear bearings with automatic greasing enhance reliability. These compressors are ideal for intermittent duty, high pressure, and medium flow in garages and small industries. Regular maintenance, including ring and valve inspection based on operating hours, is essential.You can order and buy compressor from Iran by contacting us through whatsaap and email.

WEBSITE: compressor Iran

Correct Installation Procedure for a Reciprocating Compressor

Installing a reciprocating compressor requires adherence to strict safety and technical protocols. First, prepare a vibrated concrete foundation with anti-vibration mounts. The installation location must have adequate ventilation and be free of dust and moisture. Secure the compressor to the foundation using heavy-duty galvanized bolts and nuts. Precisely align the compressor and electric motor shafts using a laser alignment tool. Connect the suction and discharge piping using flexible anti-vibration hoses with proper slope. Install an oil separator and moisture trap on the discharge line. Perform electrical wiring according to standard conduits with precise fuse and contactor calculations. After installation, lubrication, initial pressure testing, and no-load startup are mandatory. Documenting all steps in an installation report is essential for future traceability.

compressor

Centrifugal Compressor Integrally Gear

Portable Compressors

Oil Free Equipments

Industrial compressor

High Pressure Equipments

Turbo Compressors

compressor

dryer