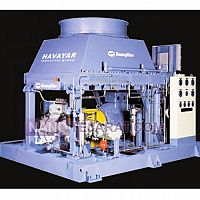

Industrial compressor , Iran

A screw compressor consists of two helical rotors male and female rotating within a cylindrical housing. These rotors operate with a manufacturing precision of 10 microns and an air gap of 0.1 mm. Their typical compression ratio is between 7 and 15 with a volumetric flow from 100 to 20,000 liters per minute. Rotors are made from forged steel coated with PTFE or DLC to reduce friction. Operating speed typically ranges from 1500 to 3600 RPM with volumetric efficiency over 90%. A VSD Variable Speed Drive control system reduces energy consumption by up to 30%.

The compressor structure includes an intake filter, compression unit, oil separator, and cooler. In oil-injected models, dedicated ISO-VG 100 oil performs cooling, lubrication, and sealing. Operating temperature in oil-injected models is controlled between 70 and 90°C. Generated noise level at one meter distance is often below 70 dB. A multi-stage oil separation system reduces oil carry-over to less than 3 ppm. These compressors are ideal for continuous operation in manufacturing industries and large workshops.You can order and buy Industrial compressor from Iran by contacting us through whatsaap and email.

WEBSITE: Industrial compressor Iran

Complete Comparison of Screw Compressor vs. Piston Compressor

A screw compressor uses two helical rotors to compress air. This type offers continuous and quiet operation, with excellent energy efficiency at high capacities. Its initial cost is higher, but maintenance and repair costs are lower due to fewer moving parts. It has a lower output air temperature and more consistent air quality. It is ideal for industrial production lines with continuous demand.

A piston compressor compresses air via the reciprocating motion of pistons. Its initial purchase cost is lower, but energy consumption during continuous operation is higher. It produces more operational noise and significant vibration. Its repairs are simpler, but it requires more frequent periodic servicing. It is suitable for intermittent use, small workshops, and very high pressures.

The final choice depends on consumption rate, budget, and operational conditions.

compressor

Centrifugal Compressor Integrally Gear

compressor

compressor

Portable Compressors

Oil Free Equipments

Turbo Compressors

dryer

High Pressure Equipments