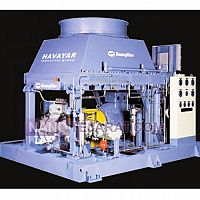

Turbo Compressors , Iran

A turbo compressor is a multi-stage dynamic centrifugal compressor. It converts kinetic energy into static pressure using a high-speed impeller. Rotational speed can range from 10,000 to 100,000 RPM. Its volumetric flow rate often reaches from 500 to 200,000 cubic meters per hour. The isentropic efficiency of these compressors is typically between 75% and 85%. Impellers are made from high-strength titanium or stainless steel alloys. Air or magnetic bearings eliminate friction and the need for lubricants.

The compressor structure includes a volute casing, diffuser, and interstage chambers. An advanced control system PLC/DCS precisely regulates operational parameters. This system prevents pressure surges and the "surge" phenomenon. Turbo compressors are typically designed for high flow rates and medium pressure up to 40 bar. Generated noise level is controlled using specialized acoustic enclosures. This equipment is widely used in industries like petrochemicals, power plants, and aerospace. Preventive maintenance is performed based on vibration analysis data.You can order and buy Turbo Compressors from Iran by contacting us through whatsaap and email.

WEBSITE: Turbo Compressors Iran

How to Service and Maintain a Turbo Compressor

Servicing a turbo centrifugal compressor requires a regular and preventive schedule. Daily monitoring of critical parameters such as vibration, temperature, pressure, and oil flow is essential. Timely replacement of air and oil filters should be done according to the manufacturers recommended intervals. Periodic inspection of bearings and the cooling system is mandatory to prevent overheating. Adjustment and calibration of control sensors must be performed every six months by a specialized technician. Cleaning of impeller and diffuser airfoils prevents contamination buildup and efficiency loss. Regular oil analysis is critical for assessing lubricant health and early detection of issues. Maintaining complete service and repair records is necessary for tracking equipment history. All service operations must comply with the manufacturers instructions and be performed by trained personnel.

Oil Free Equipments

compressor

compressor

compressor

Industrial compressor

High Pressure Equipments

Portable Compressors

Centrifugal Compressor Integrally Gear

dryer