.jpg)

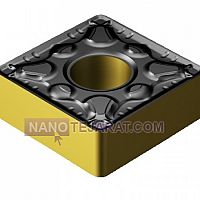

INSERT , Iran

- Price :To negotiate

- order by whatsapp

Turning inserts are replaceable cutting components used in machining tools, typically made from materials such as tungsten carbide, ceramics, CBN, or PCD. Their geometry follows ISO standard codes like CCMT, CNMG, or TNMG, each designed for specific operations. The relief angle of most inserts ranges from 5 to 11 degrees, while nose radii typically vary between 0.2 and 1.2 millimeters. Common insert thicknesses range from 2.5 to 6.35 millimeters, and their clamping systems often use screw or lever mechanisms for secure attachment.

In turning insert design, resistance to wear, high temperatures, and mechanical shocks is critical. Carbide inserts typically have a hardness around 1600 Vickers and can withstand temperatures exceeding 800 degrees Celsius. Some inserts are coated with materials such as TiN or AlTiN, which can extend tool life by up to 300 percent. Replaceable inserts improve machining accuracy, repeatability, and reduce machine downtime significantly.You can order and buy INSERT from Iran by contacting us through whatsaap and email.

WEBSITE: INSERT Iran

.jpg)

.jpg?width=200&height=200&cropratio=200:200&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (21).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (21).jpg)

.jpg?width=200&height=200&cropratio=200:200&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-download (9).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-download (9).jpg)

.jpg?width=200&height=200&cropratio=200:200&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-99b012-images (13).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-99b012-images (13).jpg)

.jpg?width=200&height=200&cropratio=200:200&image=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (9).jpg&url=/admin/uploads/اینسرت-تراشکاری-INSERT--بهرادصنعت-پارس-168-u1625-images (9).jpg)