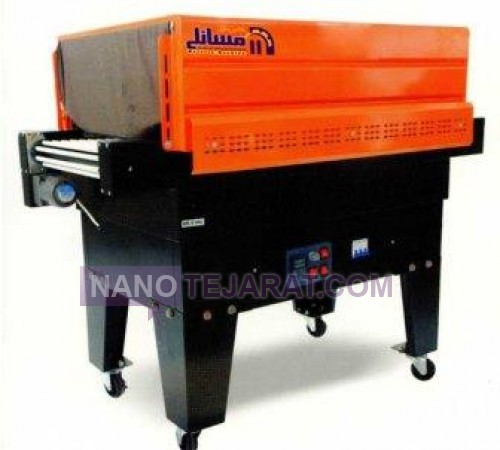

Tunnel Shrink Packaging Machine , Iran

The tunnel shrink packaging machine is built with an industrial-grade steel frame, wear-resistant powder coating, and 304 stainless steel panels. Internal tunnel dimensions are typically 1000×500×250 mm, customizable up to 3000×800×400 mm. It utilizes ceramic or quartz heating elements with 15–60 kW power and controlled temperature of 50–400°C. The conveyor system features a Teflon or steel mesh belt with widths of 300–1000 mm and variable speed of 0–20 m/min. Production capacity ranges from 20–100 packages per minute depending on product dimensions and film type. Energy consumption is 18–75 kWh with compressed air requirements of 6–8 bar.

An advanced PLC control system with a 10-inch touchscreen display and storage for 50 different profiles is integrated. Forced air distribution uses industrial centrifugal fans and steel air ducts for thermal uniformity. Infrared and laser sensors enable automatic temperature adjustment based on line speed and film thickness. It processes PE, PVC, POF, and OPS shrink films with thicknesses of 12–120 microns. External dimensions range from 2000×1000×1500 mm to 5000×1200×1800 mm. The machine complies with CE, UL, and ISO 9001 standards, featuring error alerts and production reporting systems.You can order and buy Tunnel Shrink Packaging Machine from Iran by contacting us through whatsaap and email.

WEBSITE: Tunnel Shrink Packaging Machine Iran

Key Considerations When Purchasing a Tunnel Shrink Wrapping Machine

Selecting a tunnel shrink wrapping machine requires attention to tunnel dimensions, speed, and thermal power. The tunnels length and width must accommodate the maximum package dimensions and the production line conveyor. The type and distribution of heating elements ceramic, quartz, wire directly affect film shrinkage quality. A digital temperature controller PID is essential for precise adjustment of different tunnel zones. The adjustable conveyor speed must be synchronized with production capacity. A ventilation and cooling system is mandatory for continuous operation and safety. Evaluate the machines energy consumption kW considering continuous operation. Request electrical safety certificates CE and manufacturing standards from a reputable manufacturer. After-sales service and spare parts availability are key decision-making factors.

Packing machine

masaelipacking

masaelipacking

Packing machine

Desktop Gas Flush Vacuum Sealing Machine

Fully Automatic Rock Sugar Nabat Packaging Machine

masaelimachine.com

Automatic Cup Sealing Machine

Packing machine

Packing machine