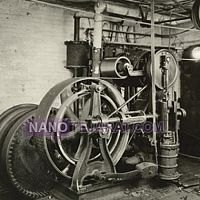

Elevator engine , Iran

- Price :To negotiate

- order by whatsapp

The geared elevator traction machine combines a three-phase induction motor with air cooling and a helical gearbox. Rated motor power ranges from 7.5 to 30 kW with speeds of 1400 to 1500 RPM. Output torque after gearing varies from 800 to 4000 Nm with gear ratios adjustable from 20:1 to 35:1. Overall system efficiency motor + gearbox reaches up to 92% under IEC 60034-30 Class IE4 standards. Permissible ambient temperature ranges from –25°C to +50°C with thermostat thermal protection in windings. Generated noise levels are below 65 dB at one meter distance per ISO 9614-2 standards.

The motor structure features a Class F insulated stator, squirrel-cage rotor, and hardened helical gears up to 58 HRC. Main bearings are rolling type with permanent lubrication and a 100,000-hour service life design. A dual-disc electromagnetic brake provides 250–3000 Nm braking torque with 100 ms response time. A separate Variable Frequency Drive VFD offers vector control capability and ±3 mm stopping accuracy. Monitoring sensors include PT100 winding temperature sensors, a 1024-pulse incremental encoder, and gearbox oil level sensors. These motors are optimized for 380V three-phase 50 Hz power supply and machine room installation. Production is certified per EN 81-1-20, ISO 22201-1, and GOST 53942 standards for safety and durability.You can order and buy Elevator engine from Iran by contacting us through whatsaap and email.

WEBSITE: Elevator engine Iran

Periodic Servicing and Maintenance of Gear Motors

Periodic servicing of gear motors is essential to maintain their efficiency and lifespan. The initial inspection includes checking the gear oil level and quality for contamination and proper level. The oil should be changed every 2000 operating hours or annually whichever comes first. Oil heating and cooling elements must be tested for proper operation. Clamps and flange connections should be checked for tightness and wear. Shaft play and abnormal noise indicate bearing or gear wear. External cleaning of the motor and cooler prevents dust accumulation. All service operations must be performed by a licensed technician in accordance with the manufacturers manual. Accurate service record-keeping is vital for preventive maintenance planning.

Cabin

elevator rail

Door Swing

Elevator

Elevator cabin

Rail Lift

Elevator

Lift engine

Lift engine

Elevator cabin