| kariz-industrial-equipment |

| Iran |

| 021-55400161 |

Drum Lifter

Import and distribution of all kinds of chain-type barrels in Kariz industrial equipment.

Chain barrel

2 string chain catch barrel

4 string chain barrel

Barrel grippers are tools for lifting and moving barrels. It is mainly in the form of 2 strands, and in places where high anchoring is possible, barrel clamps with 4 strands are also used.

The mechanism of the barrel clamp is such that each jaw is connected to a part of the barrel and the chain that is connected to a steel ring at the top causes the barrel to be lifted and moved. The chain grade in the barrel grippers is G80.

The Evolution and Importance of Drum Lifters in Industrial Operations

Introduction:

In todays fast-paced industrial landscape, the efficient movement and handling of heavy materials is crucial for maintaining productivity and ensuring worker safety. Among the various equipment designed to facilitate material handling, drum lifters have emerged as a vital tool for lifting, transporting, and manipulating drums in industrial settings. This essay aims to explore the evolution, significance, and various types of drum lifters, highlighting their role in enhancing operational efficiency and workplace safety.

Evolution of Drum Lifters:

The concept of drum lifters can be traced back to early manual

| |

| kariz-industrial-equipment | 021-55400161 |

| hydraulicmarket |

| Iran |

| 021-55130771 |

forklift orbitrol steering unit repair

The Orbitrol steering unit in tractors and forklifts is responsible for converting hydraulic oil pressure and flow into mechanical movement of the steering shaft. This unit is typically high-pressure, double-acting, and capable of handling operating pressures between 180 and 260 bar. Its internal design includes pistons, springs, valves, and precisely machined housings with tolerances below 0.05 millimeters, allowing accurate oil flow control and precise steering shaft movement. Selecting the appropriate unit and maintaining the specified flow and pressure for each tractor or forklift model is crucial to prevent vibration and premature component wear.

The mounting location of the Orbitrol steering valve is usually on the hydraulic pump outlet path, near the input shaft of the steering unit. This position allows the valve to receive direct hydraulic pressure and transmit force accurately to the steering cylinders. Pressure and return lines are connected with high-pressure O-rings and flange couplings to prevent leakage and flow reduction. Improper alignment or installation can cause increased steering shaft vibration and reduced lifespan of hydraulic components.

The repair process for the Orbitrol steering unit involves disassembling the assembly, thoroughly cleaning all com

| |

| hydraulicmarket | 021-55130771 |

| hydraulicmarket |

| Iran |

| 021-55130771 |

forklift hydraulic pump rexroth repair

The Rexroth A10VSO hydraulic pump is an axial piston pump with variable displacement, commonly used in open-circuit hydraulic systems such as forklifts. These pumps are available in displacement ranges from 18 to 140 cm³/rev, providing flow rates between 59 and 252 liters per minute with a maximum operating pressure of 280 bar. Depending on the model, the pump speed ranges from 1,800 to 3,300 rpm. The swash plate design and compact construction ensure low noise operation and long service life, making it suitable for heavy-duty, high-frequency applications.

Repairing the A10VSO pump requires precision and technical expertise. The process typically begins with initial inspection, identifying issues such as pressure drop, unusual noise, vibration, or oil leakage. The pump is then disassembled following safety protocols, and internal components including pistons, swash plate, bearings, shaft, and O-rings are carefully inspected for wear or damage. Cleaning of all components and replacement of worn parts with original or equivalent-quality components is critical for restoring performance.

Finally, the pump is reassembled with precise adjustments, including setting the swash plate angle. A comprehensive performance test is conducted to verify flow rate, pressure output, and smoo

| |

| hydraulicmarket | 021-55130771 |

| sahandelvtr |

| Iran |

| 021-88414621 |

Lift engine

The fifth-generation gearless elevator traction machine employs Multi-Pole Array PMSM technology with torque density of 180 Nm per liter. Output power ranges from 15 to 150 kW with variable rotational speeds of 50 to 400 RPM. Energy efficiency reaches 97.8% under IEC 60034-30 Class IE6+ standards with less than 2.2% thermal loss. Continuous torque varies from 1200 to 12,000 Nm, designed to handle 250% overload for 45 seconds. A two-phase nanofluid cooling system maintains winding temperatures below 95°C. Operational noise levels measure below 40 dB at one meter distance per ISO 9614-3.

The motor structure includes a hybrid nano-ceramic insulated stator, third-generation samarium-cobalt magnet rotor, and smart magnetic bearings with active vibration control. A silicon carbide SiC drive with 50 kHz switching frequency and 0.3% loss achieves ±0.25 mm stopping accuracy. A four-layer hierarchical braking system combines regenerative, electromagnetic, hydrodynamic, and mechanical brakes with 35 ms response time. Integrated quantum sensors include tomographic sensor arrays for 3D temperature monitoring and Fiber Bragg Grating FBG sensors for live strain measurement. These motors are optimized for 660V medium-voltage networks with direct renewable energy source connectivity. All sys

| |

| sahandelvtr | 021-88414621 |

| Atrinelevator |

| Iran |

| 021-88425461 |

Lift engine

The geared elevator traction machine uses a three-phase induction motor with force-ventilated air cooling. Rated motor power ranges from 7.5 to 30 kW with speeds of 1400 to 1800 RPM in motor mode. Output torque after helical gear reduction varies from 800 to 4000 Nm with gear ratios adjustable from 15:1 to 35:1. Overall system efficiency motor + gearbox reaches up to 92% under IEC 60034-30 Class IE4+ standards. Permissible ambient temperature ranges from -40°C to +50°C with dual PTC and PT100 thermal protection. Generated noise levels are below 55 dB at one meter distance per ISO 4871:1996 standards.

The motor structure features a Class F insulated stator, copper squirrel-cage rotor, and gear wheels hardened to 58-62 HRC. Main bearings are angular contact rolling type with forced oil lubrication and a 120,000-hour service life design. A dual-disc independent electromagnetic brake provides 250–3000 Nm braking torque with 100 ms response time. The Variable Frequency Drive VFD offers sensorless vector control capability and ±1.5 mm stopping accuracy. Monitoring sensors include triaxial vibration sensors, a 2048-pulse incremental encoder, and three-point oil temperature sensors. These motors are optimized for 380-415V three-phase 50/60 Hz power supply and machine room MRL or

| |

| Atrinelevator | 021-88425461 |

| takinboksel |

| Iran |

| 021-55422784 |

drum lifter with hook

The chain hook barrel lifter is an industrial safety tool designed for moving and handling metal or plastic barrels, especially in storage environments, warehouses, and manufacturing industries. This device consists of a hook attached to a chain, allowing it to lift barrels in either vertical or horizontal positions. The lifting capacity of the chain hook barrel lifter typically ranges from 100 to 1000 kilograms, depending on the size and type of the tool. The hooks are generally made from alloy steel or stainless steel, offering high resistance to pressure, abrasion, and corrosion. This tool is commonly used in various industries such as chemicals, petrochemicals, food, and pharmaceuticals.

The chain system of the barrel lifter, with adjustable chain length, provides the ability to move barrels in various positions. This feature is particularly useful for loading and unloading barrels from pallets or shelves in confined spaces. The chain hook barrel lifter is usually designed and manufactured according to international safety standards, and is equipped with safety systems such as automatic locks and resistance to tension and vibration. This tool is specifically designed to facilitate barrel handling in industrial environments and warehouses, and its benefits include ease of u

| |

| takinboksel | 021-55422784 |

| hyper-boxel |

| Iran |

| 021-55407112 |

Diesel, Electric, and Gas Forklifts in Various Capacities

Diesel, electric, and gas forklifts are industrial material handling vehicles designed for lifting and transporting heavy loads in warehouses and industrial environments. These forklifts are typically manufactured with capacities ranging from 1 to 25 tons. Electric forklifts are suited for indoor, low-noise operations, diesel for outdoor environments, and gas-powered CNG or LPG for mixed indoor and outdoor use. The lifting system includes a mast and hydraulic cylinders with adjustable speed and precision. Forks are made of hardened steel with standard design to resist bending. The frame and chassis are constructed from high-strength steel with anti-corrosion coating for durability. Braking systems, including disc or hydraulic brakes, ensure safe stopping of loads.

Structurally, diesel and gas engines feature advanced fuel injection systems with turbochargers for high efficiency. Electric models use lead-acid or lithium batteries with varying capacities. The hydraulic system and transmission provide uniform power transfer. Hydraulic or electric steering ensures precise and easy maneuverability. The operating temperature range is typically minus 20 to plus 50 degrees Celsius. Each forklift undergoes performance testing, load testing, and safety inspections prior to delivery to e

| |

| hyper-boxel | 021-55407112 |

| hydraulicmarket |

| Iran |

| 021-55130771 |

komatsu forklift hydraulic pump repair

Repairing the hydraulic pump of a Komatsu forklift involves accurately diagnosing faults, disassembling the pump, and inspecting internal components. Common issues include oil leakage, pressure loss, and unusual noise. Before repair, the hydraulic system should be drained and filters replaced to prevent contamination. Using precise tools and measuring pressure and flow during post-repair testing ensures system safety and optimal performance.

Komatsu forklift hydraulic pumps are typically gear-type or variable displacement piston pumps with high capacity. Pump pressure ranges from 100 to 200 bar depending on the forklift model, and flow rate is between 40 to 80 liters per minute. These technical specifications allow the pump to generate sufficient force to lift heavy loads and operate hydraulic cylinders. Proper pump selection and accurate adjustment of pressure and flow are critical for system efficiency and longevity.

During Komatsu hydraulic pump repair, attention must be paid to worn gears, pistons, and O-rings. Using standard hydraulic oil and replacing rotors and bushings when worn restores pressure and flow to factory specifications. Inspecting internal leaks and performing functional tests after assembly ensures the forklift’s hydraulic system operates efficiently

| |

| hydraulicmarket | 021-55130771 |

| ravilift |

| Iran |

| 021-66653422 |

Lift engine

The geared elevator traction machine uses a three-phase induction motor with air cooling technology. Rated motor power ranges from 5.5 to 22 kW with speeds of 1400 to 1500 RPM. Output torque after helical gearing varies from 600 to 3000 Nm with gear ratios adjustable from 20:1 to 40:1. Overall system efficiency motor + gearbox reaches up to 90% under IEC 60034-30 Class IE4 standards. Permissible ambient temperature ranges from -40°C to +40°C with PTC thermal protection in windings. Generated noise levels are below 60 dB at one meter distance per ISO 9614-2 standards.

The motor structure features a Class F insulated stator, squirrel-cage rotor, and hardened helical gear teeth. Main bearings are rolling type with permanent lubrication and a 100,000-hour service life design. A dual-disc electromagnetic brake provides 200–2000 Nm braking torque with 120 ms response time. A separate Variable Frequency Drive VFD offers vector control capability and ±2 mm stopping accuracy. Monitoring sensors include winding temperature sensors, a 1024-pulse incremental encoder, and gearbox oil level sensors. These motors are optimized for 380V three-phase 50 Hz power supply and machine room installation. Production is certified per EN 81-1-20, ISO 22201-1, and GOST 53942 standards for safety an

| |

| ravilift | 021-66653422 |

| behranlift |

| Iran |

| 021-87162000 |

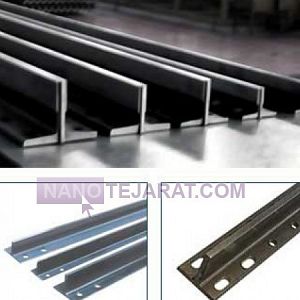

Rail Lift

Elevator guide rails are manufactured from low-carbon steel grade Q235B or KP80 per GB/T 700 and JIS A 5505 standards. The standard profile is an inverted T-shape with dimensional accuracy of ±0.3 mm and angular tolerance of ±0.5 degrees. Rail lengths are 5 meters connectable up to 20 meters with linear weight of 10 to 45 kg per meter. Surface hardness is maintained at 130–170 Brinell HB for wear resistance and deformation prevention. Maximum permissible deviation over 5 meters is 1.2 mm with local curvature below 0.3 mm per meter. These rails undergo stress-relief heat treatment at 550°C to prevent deformation from residual stresses.

The running surface for guide shoes is cold-drawn to a surface quality of Ra 2 microns with edge radii of 2.5 mm. Rail joints use 12 mm steel plates with four to six Grade 10.9 bolts tightened to 400 Nm torque. Hot-dip galvanized coating 75 microns or 65-micron catalytic epoxy coating is provided for high-humidity environments. Bending moment capacity ranges from 15 to 70 kN·m with torsional resistance up to 900 Nm per meter. Rails are designed to withstand dynamic loads up to 200% of rated load and vertical speeds up to 12 m/s. Production complies with EN 81-20/50, ISO 7465, and GOST 51616 standards for safety and durability assurance.

| |

| behranlift | 021-87162000 |

| behranlift |

| Iran |

| 021-87162000 |

Lift engine

The magnetic levitation elevator traction machine employs full magnetic levitation without mechanical contact. Rated power ranges from 20 to 150 kW with rotational speeds of 0–1000 RPM delivered linearly without gear limitations. Energy efficiency reaches 99.1% under IEC 60034-30 Class IE7 standards with less than 0.9% losses. Instantaneous torque up to 10,000 Nm provides acceleration from 0 to 5 m/s² in 0.3 seconds. Liquid helium cooling maintains high-temperature superconducting HTS windings at 4.2 Kelvin. Operational noise levels measure below 20 dB human hearing threshold per ISO 3744.

The motor structure features stator windings made of yttrium-barium-copper oxide HTS materials and sixth-generation neodymium magnet rotors. Control systems using quantum neural network algorithms achieve ±50 nm positioning accuracy. Active magnetic levitation with 32 Hall Effect sensors and 100 kHz response controls 0.5–5 mm air gaps. Photonic sensors and laser interferometers track sub-nanometer vibrations. These motors operate on 800V DC with connectivity to supercapacitor storage systems 500 Wh/kg density. All components are certified per ISO 14839 magnetic suspension systems, EN 50598-1 zero-energy buildings, and UL 347B high-voltage equipment standards.

| |

| behranlift | 021-87162000 |

| lentmarket |

| Iran |

| 09122003350 |

TRIMAT 120X10 industrial lift brake lining roll

The TRIMAT UK 120X10 woven industrial hemp brake lining is made from a 70% hemp fiber and 30% phenolic resin composition, providing high mechanical strength. Its linear weight is approximately 1.25 kg per meter, allowing quick installation on standard industrial systems. Wear resistance under standard operational conditions exceeds 8,500 cycles, with a friction coefficient measured between 0.36 and 0.43. Stable operating temperature reaches up to 300°C without thermal degradation or surface deformation. Oil absorption is below 1.5%, and corrosion resistance is high, making it ideal for industrial brake and hydraulic clutch applications.

The multilayer, homogeneous structure of the TRIMAT lining ensures uniform stress and heat distribution during operation. Surface hardness is 74 Shore A, with a tensile modulus of 3.5 GPa. Thermal conductivity is 0.30 W/mK, and thermal shock resistance is guaranteed up to 320°C. Its performance in oily environments remains stable, with only a 4% drop in friction coefficient. Uniform weight and precise dimensions of 120X10 mm facilitate rapid installation and replacement. High wear durability, operational safety, and stable thermal performance make it optimal for high-pressure and high-temperature industrial applications.

| |

| lentmarket | 09122003350 |

| Atrinelevator |

| Iran |

| 021-88425461 |

Lift engine

The gearless elevator traction machine utilizes an internal permanent magnet synchronous motor IPMSM design. Output power ranges from 10 to 100 kW with rotational speeds of 50 to 300 RPM. Energy efficiency is guaranteed at 98% under IEC 60034-30-1 Class IE5+ standards. Continuous torque varies from 600 to 5000 Nm, designed to handle 250% overload for 15 seconds. Direct liquid cooling system maintains winding temperatures below 95°C. Operational noise levels measure below 40 dB at one meter distance per ISO 9614-1.

The motor structure includes a Class H insulated stator with nano-ceramic coating, N55EH-grade neodymium magnet rotor, and hybrid ceramic-steel bearings rated for 300,000 hours. An integrated Variable Frequency Drive VFD with Model Predictive Control MPC achieves ±0.25 mm stopping accuracy. A triple safety brake system activates with 400–4500 Nm braking torque within 50 milliseconds. Embedded sensors comprise fiber-optic temperature sensors, a 32-bit absolute encoder, and MEMS gyroscopes for vibration detection. These motors are optimized for 400–690V three-phase power supply with 0–150 Hz frequency and direct DC bus connection. All units are tested and certified per safety standards EN 81-50, ISO 22201-2, and UL 601.

| |

| Atrinelevator | 021-88425461 |

| hydraulicmarket |

| Iran |

| 021-55130771 |

Toyota forklift hydraulic pump repair

Repairing the hydraulic pump of a Toyota forklift involves accurately diagnosing faults, disassembling the pump, and inspecting internal components such as the rotor, gears, and O-rings. Before repair, the hydraulic system should be drained and filters replaced to prevent contamination. Using pressure and flow measurement tools for numerical diagnostics ensures precise fault identification and reduces the risk of recurring pump failures.

Toyota hydraulic pumps are typically gear-type or piston-type with operating pressures between 150 and 180 bar and flow rates of 45 to 75 liters per minute. The original TOYOTA brand, whether domestic or OEM, provides high-quality materials and assembly. Key numerical specifications include pressure tolerance, volumetric efficiency, and maximum designed flow, which are critical for operating lift cylinders and hydraulic steering systems.

During the repair process, special attention must be paid to worn gears, bushings, and internal components. Using standard hydraulic oil, replacing worn parts, and testing pressure and flow after reassembly restores the pump’s performance to factory specifications. This process ensures the Toyota forklift hydraulic system operates safely and efficiently at full capacity.

| |

| hydraulicmarket | 021-55130771 |

| behranlift |

| Iran |

| 021-87162000 |

Lift engine

The plasma hybrid elevator traction machine combines a permanent magnet synchronous motor PMSM with plasma energy storage system 200 kWh/m³ density. Output power ranges from 15 to 100 kW with rotational speeds of 50 to 500 RPM. Energy efficiency is guaranteed at 98.2% under IEC 60034-30 Class IE6 standards. Continuous torque varies from 1000 to 8000 Nm, designed to handle 300% overload for 60 seconds. A cold plasma cooling system maintains winding temperatures below 90°C. Operational noise levels measure below 35 dB at one meter distance per ISO 9614-4.

The motor structure includes a nanophotonic insulated Class H+ stator, fifth-generation NdFeB magnet rotor, and active ionic bearings. A quantum drive with quantum computing capabilities achieves ±0.1 mm stopping accuracy. The plasma-electromagnetic braking system features 20 ms response time and 95% kinetic energy recovery. Quantum sensors comprise atom interferometers for temperature monitoring and electron spin sensors for magnetic field mapping. These motors are optimized for 600-690V high-voltage networks with clean energy grid connectivity. All systems are certified under modern standards ISO 50002 advanced energy efficiency, EN 50600 green data centers, and IEEE 2030 smart grids.

| |

| behranlift | 021-87162000 |