| bakutools |

| Iran |

| 09123691065 |

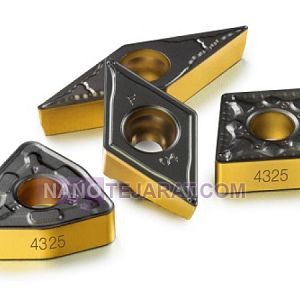

Walter LNGX130708R-L55 diamond turning tool

The Walter LNGX130708R-L55 diamond insert is a geometrically optimized tool designed for milling hard alloys and non-ferrous metals. This insert has standard dimensions of 13.00 × 7.00 × 8.00 mm and complies with the DIN ISO coding system. A positive cutting angle and 0.8 mm nose radius provide high precision in high-speed machining applications. The insert is made from a carbide grade coated with aluminum titanium nitride AlTiN, offering excellent resistance to wear and high temperatures. The R right-hand cutting orientation is intended for unidirectional cutting paths and ensures effective chip evacuation. These features make the LNGX130708R-L55 an ideal choice for finishing and semi-roughing operations.

This insert features the L55 geometry, which includes a precision rake angle to reduce cutting forces and enhance surface finish quality. The 3D chipbreaker design ensures tool stability during high-speed operations. It is compatible with Xtra·tec® Walter toolholder systems and utilizes a precise mechanical clamping system. Each insert weighs approximately 5.4 grams, balancing strength and lightness. The high-temperature-resistant coating allows operation at up to 900°C. Under standard working conditions, this tool offers up to 30 percent longer service life compared to

| |

| bakutools | 09123691065 |

| bakutools |

| Iran |

| 09123691065 |

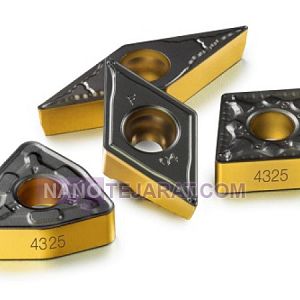

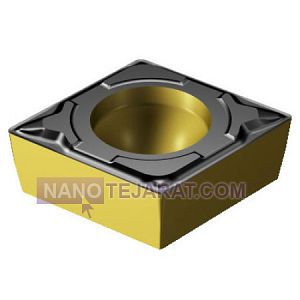

Walter CNMG190612-RM5 Diamond Turning Insert

The Walter CNMG190612-RM5 diamond turning insert is a precision-engineered square insert designed for machining hardened steels, cast iron, and heat-resistant alloys. It features dimensions of 19.05 × 6.35 mm with a 1.2 mm nose radius and conforms to the CNMG ISO standard. Its negative rake angle and balanced thickness enable stable cutting under heavy load conditions. The carbide grade used in combination with AlTiN and TiCN multilayer coatings extends tool life by up to 30% compared to similar inserts. The RM5 geometry is optimized for medium to semi-rough turning and delivers effective chip control at high speeds. This insert performs reliably in both continuous and interrupted cutting operations.

The insert’s engineering is based on precision pressing technology and nano-layered coatings, which significantly enhance its mechanical and thermal resistance. The applied cutting geometry evenly distributes stress across the cutting edge, preventing premature cracking. Its optimized corner design improves final surface finish and reduces the need for secondary polishing. Each insert weighs approximately 14.8 grams, striking a balance between mass and rigidity. Compatibility with standard ISO toolholders enables fast tool changes and boosts productivity in manufacturing enviro

| |

| bakutools | 09123691065 |

| bakutools |

| Iran |

| 09123691065 |

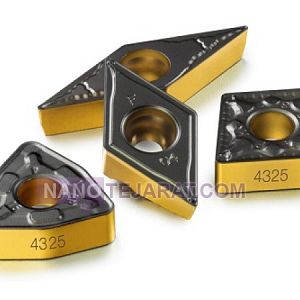

Walter CCMT 120408-PM5 Diamond Turning Tool

The Walter diamond cutting tool model CCMT 120408-PM5 is a precise and durable instrument designed for machining hard and resistant materials such as hardened steels, heat-resistant alloys, and ceramics. This diamond tool utilizes industrial diamond with exceptionally high hardness and a uniform crystalline structure, featuring a very sharp and resilient tip that enables machining operations with high accuracy and superior surface quality. Its optimized cutting angle design and unique geometry reduce cutting forces, improve chip evacuation, and extend tool life. Additionally, this diamond can withstand very high temperatures in high-speed cutting processes, making it highly suitable for advanced industrial applications.

Structurally, the CCMT 120408-PM5 model by Walter is manufactured as replaceable inserts with advanced nano and ceramic coatings that offer high resistance to wear and corrosion. These coatings reduce friction and prevent heat buildup, delivering outstanding performance in tough and complex machining conditions. The edge thickness, cutting angle, and specific geometry of this diamond allow precise and stable installation on CNC machines, making it ideal for high-quality production processes. Strict adherence to technical and structural standards in the design o

| |

| bakutools | 09123691065 |

| bakutools |

| Iran |

| 09123691065 |

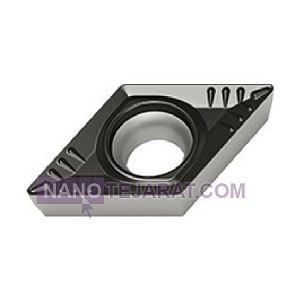

Diamond turning insert TNMG220408-MS3

The technical specifications of the TNMG220408-MS3 diamond cutting insert feature high precision and notable wear resistance, designed for machining hard and semi-hard materials. This insert is made from synthetic diamond with a hardness exceeding 9500 Vickers and can withstand temperatures up to 800 degrees Celsius. Its dimensions include a cutting length of 22 millimeters, a thickness of 4 millimeters, and an 80-degree nose angle, which enhances cutting accuracy and reduces cutting forces. The TNMG220408-MS3’s geometric design minimizes vibrations and increases tool life by up to 30 percent. It supports high cutting speeds up to 150 meters per minute, making it highly suitable for aerospace and automotive industries.

The structure of this diamond cutting insert incorporates multi-layer coatings such as TiAlN, which improve resistance to oxidation and wear. The low friction coefficient of these coatings reduces chip adhesion and enhances surface finish quality. With a positive rake angle and optimized chip breakers, the TNMG220408-MS3 facilitates chip flow and decreases tool load. Weighing approximately 8 grams, it balances strength and lightness effectively. These features make the TNMG220408-MS3 an ideal choice for precision machining and mass production across various in

| |

| bakutools | 09123691065 |

| bakutools |

| Iran |

| 09123691065 |

Diamond turning insert TNMG160412-MP5

The TNMG160412-MP5 diamond cutting tool is a popular and widely used instrument in the machining industry, designed for precise and efficient material removal from various hardened steels, heat-resistant alloys, and non-ferrous metals. Made from industrial diamond with high hardness and a uniform crystalline structure, this tool features a specially designed tip and optimized cutting angle that help reduce cutting forces and improve surface finish quality. Its high resistance to wear and heat makes it highly suitable for high-speed machining operations and demanding working conditions.

Structurally, the Walter TNMG160412-MP5 is manufactured as replaceable inserts with advanced nano and ceramic coatings that play a significant role in reducing friction and enhancing tool durability. The edge thickness, precise tip geometry, and easy mounting capability on CNC machines make this diamond cutting tool an ideal choice for industries such as automotive, aerospace, and mold making. Adherence to strict technical and structural standards in the design and production of this tool ensures increased productivity, reduced manufacturing costs, and improved final part quality.

| |

| bakutools | 09123691065 |

| bakutools |

| Iran |

| 09123691065 |

Diamond turning insert TNMG220412-NR4

The TNMG220412-NR4 turning diamond features an advanced TiN/TiCN coating that provides high resistance to wear and heat. This insert is designed with a cutting length of 22 millimeters and a thickness of 4.12 millimeters to deliver precise machining of various hard steels. Its 80-degree nose angle increases tool strength and reduces mechanical stress. The specially engineered chip breakers optimize chip flow and minimize vibrations during turning. The tool weighs approximately 7.5 grams and can withstand cutting speeds up to 140 meters per minute. These features contribute to longer tool life in automotive and aerospace industries.

Additionally, the structural design of the TNMG220412-NR4 turning diamond helps reduce heat in the cutting zone, maintaining high surface quality of machined parts. Its high impact resistance and reduced wear lower tool replacement costs. With precise engineering, this turning diamond performs optimally in machining hard and semi-hard metals. Overall, the TNMG220412-NR4 is an ideal choice for industrial applications demanding durability and high accuracy.

| |

| bakutools | 09123691065 |

| TSK-tools |

| Iran |

| 02166747975 |

Diamond Turning Insert WNMG 060404 EM YBG202

The WNMG 060404 EM YBG202 turning insert features standard dimensions of 6.35 × 6.35 millimeters with a nose radius of 0.4 millimeters, designed for precise turning and finishing operations. This insert is made of YBG202 grade carbide, offering a combination of high hardness and excellent wear resistance. Its multi-layer TiAlN coating ensures thermal resistance up to 950 degrees Celsius, enhancing tool performance under demanding conditions. The WNMG geometry with a medium rake angle and optimized design provides controlled chip flow and reduces vibration during cutting.

The YBG202 grade of the WNMG 060404 EM insert is optimized for machining alloy steels and medium hardness carbon steels. The insert thickness is 4.76 millimeters, balancing strength and flexibility. Due to its high wear resistance and thermal stability, this tool offers a long service life in heavy industrial applications. Additionally, the 7-degree rake angle reduces cutting forces and improves surface finish quality. The WNMG 060404 EM YBG202 insert is compatible with standard ISO tool holders.

| |

| TSK-tools | 02166747975 |

| BOR |

| Iran |

| 09902245921 |

| |

| BOR | 09902245921 |

| BOR |

| Iran |

| 09902245921 |

| |

| BOR | 09902245921 |

| jafar-esmaili-t |

| Iran |

.jpg?width=160&height=160&cropratio=160:160&image=/admin/uploads/ضایعات-الماس-تراشکاری-و-تنگستن-کارباید-Diamond-turning-wastes-and-tungsten-carbide-ضایعات-الماس-تراشکاری-سرو-صنعت--168-u1631-318f4d-download (1).jpg&url=/admin/uploads/ضایعات-الماس-تراشکاری-و-تنگستن-کارباید-Diamond-turning-wastes-and-tungsten-carbide-ضایعات-الماس-تراشکاری-سرو-صنعت--168-u1631-318f4d-download (1).jpg)

.jpg?width=300&height=300&cropratio=300:300&image=/admin/uploads/ضایعات-الماس-تراشکاری-و-تنگستن-کارباید-Diamond-turning-wastes-and-tungsten-carbide-ضایعات-الماس-تراشکاری-سرو-صنعت--168-u1631-318f4d-download (1).jpg&url=/admin/uploads/ضایعات-الماس-تراشکاری-و-تنگستن-کارباید-Diamond-turning-wastes-and-tungsten-carbide-ضایعات-الماس-تراشکاری-سرو-صنعت--168-u1631-318f4d-download (1).jpg) | |

| jafar-esmaili-t | |

| T-A-Z |

| Iran |

| 02166736702 |

| |

| T-A-Z | 02166736702 |

| T-A-Z |

| Iran |

| 02166736702 |

| |

| T-A-Z | 02166736702 |