V-shaped belt

The V-belt is one of the most widely used components for power transmission in mechanical and industrial systems. Its trapezoidal cross-section allows it to fit securely into pulley grooves, preventing slippage. These belts are typically made from durable rubber combined with reinforcing fibers such as polyester or Kevlar, providing high tensile strength and resistance to wear and heat. The unique design of the V-belt increases friction between the belt and the pulley, ensuring efficient and slip-free power transfer.

V-belts come in various types, including classical, narrow, cogged, and multi-ribbed designs, each suited for specific applications in automobiles, industrial machinery, HVAC systems, and agricultural equipment. The service life of these belts can vary from several thousand to tens of thousands of kilometers depending on working conditions, load, rotational speed, and build quality. Using a high-quality V-belt that meets the technical specifications of the equipment helps reduce energy consumption, extend equipment lifespan, and optimize overall system performance. Regular inspection, proper tensioning, and timely replacement of the belt play a crucial role in preventing sudden failures and operational downtime.

Plain coated V-belt

.jpg?width=215&height=192&cropratio=215:192&image=/admin/uploads/تسمه-وی-شکل-دنده-ای-Ribbed-V-belt-پاور-بلت-94-u3092-4c21b7-New Project (5).jpg&url=/admin/uploads/تسمه-وی-شکل-دنده-ای-Ribbed-V-belt-پاور-بلت-94-u3092-4c21b7-New Project (5).jpg)

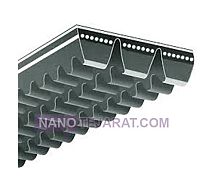

Ribbed V-belt

Special coated V-belt

BANDO V-belt

OPTIBELT V-belt, Germany

V-belt Megadyne Germany

OPTIBELT ceramic tile V-belt from Germany

Polycord tile strap

.jpg?width=215&height=192&cropratio=215:192&image=/admin/uploads/تسمه-وی-بلت-پلی-یورتان-PU-Polyurethane-PU-V-belt-پاور-بلت-94-u3092-d0e84c-New Project (5).jpg&url=/admin/uploads/تسمه-وی-بلت-پلی-یورتان-PU-Polyurethane-PU-V-belt-پاور-بلت-94-u3092-d0e84c-New Project (5).jpg)

Polyurethane PU V-belt

V-belt with grooves

CX150 V-Belt

Gates BX97 V-belt

Gates BX24 V-belt

Bando 3V475 V-Belt

Bando 5VX810 V-Belt

Bando BX105 V-Belt

Optibelt SPB 1000 V-belt

Bando Rib Ace J V-Belt

Bando AA Double V V-Belt

Bando BB Double V V-Belt

Bando CC Double V V-Belt

Bando Duraflex 3L V-belt

Bando Duraflex 4L V-belt

Bando Power Ace 3VX power transmission belt

Gates V-belt model BX30

Gates V-belt model BX36

Gates V-belt model AX30

Gates V-belt model AX40

Gates V-belt model BX180

Gates V-belt model CX51

Gates V-belt model CX100

Gates CX300 V-belt

Gates CX190 V-belt

Gates CX210 V-belt