Elevator control board. , Iran

The elevator control panel is constructed from 1.5–2.5 mm thick galvanized steel or stainless steel metal sheets. Standard dimensions range from 800x600x200 mm to 1200x800x300 mm with IP54 protection rating for dusty and humid environments. The control system utilizes PLC or microprocessor-based technology with 32-bit processors, 1 GB memory, and 1000 command/sec processing capacity. The panel incorporates a Variable Frequency Drive VFD with 5.5–60 kW power range and 0.01% speed control accuracy. Communication modules include industrial Ethernet Profinet/EtherCAT, CANopen protocol, and RS-485 connectivity for Building Management System BMS integration. All equipment is certified per IEC 60364, EN 81-20, and UL 508A standards.

Internal structure comprises power supply section 380-480VAC three-phase input, control unit, and motor drive section. The system includes circuit breakers 10–200A range, overload relays, and surge protection devices. A touchscreen HMI display 7–15 inches, 1280x800 pixels with 100,000 event logging capability is installed. Integrated sensors include current monitoring CT sensors ±0.5% accuracy, motor temperature monitoring, and encoders with 1024 pulses/revolution resolution. The system features automatic self-diagnostics with 200 error codes and remote access via Modbus TCP/IP protocol. Installation and commissioning utilize dedicated software with precise motion parameter calibration per EN 81-50 guidelines.You can order and buy Elevator control board. from Iran by contacting us through whatsaap and email.

WEBSITE: Elevator control board. Iran

How to Service and Maintain the Elevator Control Panel Periodically

Periodic servicing of the elevator control panel is critical for ensuring precise and safe system operation. This process must be performed by a licensed technician with the power completely disconnected. Internal cleaning of dust using compressed air and a soft brush. Visual inspection to identify loose connections, signs of burning, or corrosion on components is essential. Tightening clamp and terminal connections prevents overheating. Checking and testing relays, contactors, and power circuits with precision instruments. Updating controller software if available is recommended. Full system function test including response to commands and sensors after servicing is mandatory. Accurate recording of all actions in the service report for maintenance history tracking.

Lift engine

Elevator

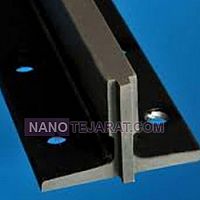

elevator rail

Elevator cabin

elevator rail

Elevator cabin

elevator Parachute

Elevator

Lift engine