HPR130 ROTARY GROUP , Iran

- Price :To negotiate

- order by whatsapp

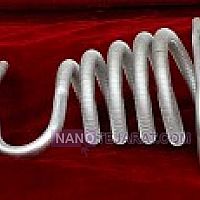

The HPR130 rotary group is a radial piston pump/motor with variable displacement and advanced electro-hydraulic control. Its main housing is machined from EN AW-7075 T651 aluminum alloy with 500 MPa yield strength. The cylinder block is designed from hardened 34CrAlNi7 steel with 7 radial pistons and needle roller bearings. The control system utilizes a two-stage servo valve with 15-millisecond response and 0.1% positioning accuracy. This unit manages 450 bar continuous operating pressure and 500 bar peaks per ISO 5 standards. Nominal flow reaches 130 liters per minute at 2000 RPM and maximum displacement. Volumetric efficiency under rated conditions is 98% with 94% overall efficiency.

The intelligent control structure includes an independent Processing Unit IPU with CAN BUS interface and J1939 protocol. An integrated cooling system with a plate heat exchanger and PID temperature control operates continuously. The output shaft is manufactured from maraging steel 300 with a WC/C Tungsten Carbide/Carbon coating. The hydraulic fluid operating temperature range is defined between -40°C to +130°C. Generated noise level at nominal pressure and one-meter distance measures below 68 decibels A-weighted. A dual filtration system with 5 and 15-micron ratings and an online contamination sensor is installed. The design service life until first overhaul under severe operating conditions is 25,000 hours.You can order and buy HPR130 ROTARY GROUP from Iran by contacting us through whatsaap and email.

WEBSITE: HPR130 ROTARY GROUP Iran

Step-by-Step Guide to Adjusting a Rotary Group

Step 1: Safety and Preparation

Completely disconnect the systems power and pressure supply. Drain the oil and check its level.

Step 2: Initial Inspection

Check gaskets, seals, and connections for leaks or damage.

Step 3: Mechanical Adjustment

Using the adjustment screw on the housing, change the angle of the swash plate. This adjusts the pumps flow rate. A small change e.g., 1 to 2 degrees can have a significant effect.

Step 4: Pressure Adjustment

Tighten or loosen the pressure adjustment screw on the relief valve using a torque wrench. This controls the systems maximum output pressure.

Step 5: Testing and Monitoring

After starting the system, measure flow rate, pressure, and oil temperature under no-load and loaded conditions. Check for any fluctuations or abnormal noises.

Step 6: Final Adjustment

If necessary, repeat steps 3 and 4 more precisely until the parameters reach the desired values. Finally, tighten all locking screws securely.