| Exporter,Importer,Manufacturer,Wholesaler,Retailer | |

| Tehran | |

| 02155433645 | |

| rahsaz_market_iran@gmail.com | |

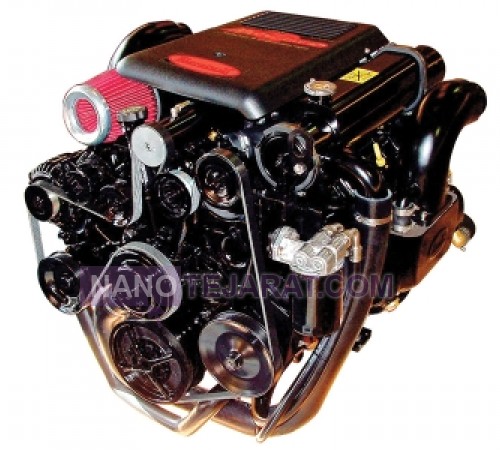

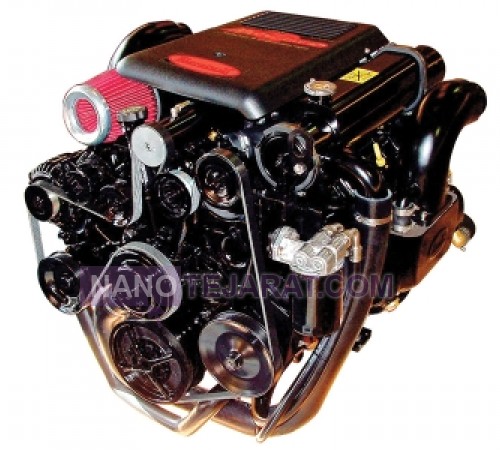

Maintenance of various superchargers includes inspecting the turbine, compressor, central shaft, bearings, and lubrication system to optimize engine performance and outlet air pressure. Supercharger operating pressure ranges from 1.5 to 2.2 bar, and the central shaft is installed with tolerances below 0.005 millimeters to reduce vibration and wear. Compressor and turbine blades are hardened to 50–55 Rockwell C to withstand rotational speeds up to 100,000 RPM. Lubrication uses standard engine oil and cooling with water or oil to maintain safe temperatures and increase service life.

The weight of a supercharger assembly varies from 15 to 50 kilograms depending on the model, with assembly using grade 12.9 bolts. Turbine and compressor geometry is optimized using CAD software and CFD analysis to ensure uniform airflow and volumetric efficiency up to 87 percent. Leakage inspection, bearing replacement, and lubrication system review after maintenance ensure reliable performance and a service life exceeding 12000 hours. Anti-corrosion and heat-resistant coatings are applied to blades and housing to increase durability under high temperature and environmental conditions.

WEBSITE: Maintenance of various superchargers Iran