- Pneumatic tools

- Hand tools

- Hydraulic tools

- Pipe fittings

- Nuts,Bolts and Screws

- Welding and Soldering

- Steel Wire rope and accessories

- steel Wire rope(8)

- escalator handrail(4)

- Sling(3)

- elevator guide shoe(3)

- steel wire rope(2)

- elevator traction machine(2)

- PP Rope(2)

- elevator sliding guide shoe(2)

- Polypropylene marine ropes(2)

- Drilling ropes(2)

- elevator steel wire rope(2)

- ESAB(1)

- Stainless steel pully(1)

- Chain sling with one and multipple legs(1)

- Wire Rope 6X19 IWRC(1)

- Tower Crane Wire Rope(1)

- wire(1)

- non-rotating ungalvanized steel wire rope(1)

- Power Winches(1)

- G80 welded master link(1)

- webbing sling(1)

- escalator step roller(1)

- Marine ropes(1)

- PP rope(1)

- thin stainless steel wire rope(1)

- Wire Rope 6X37 IWRC(1)

- Non-rotating Wire Rope(1)

- Chains(1)

- Electric winch(1)

- Electric Chain Hoist with manual Trolley(1)

- elevator balance compensation chain(1)

- steel wire rope with fiber core(1)

- rope(1)

- Galvanized Steel Wire Rope(1)

- american webbing sling(1)

- Chain Slings(1)

- Mechanical Jacks(1)

- CLIPS(1)

- elevator rope attachment(1)

- ropes(1)

- PP marine ropes(1)

- marine ropes(1)

- FC wire rope(1)

- Steel Wire Rope(1)

- Drilling ropes(1)

- Mechanical Winch(1)

- galvanized steel wire rope(1)

- Valves

- Spring

- Electrical tools

- LED board

- GPS

- Cable, Wire and Accessories

- UPS and Battery

- Bus and Minibus

- Car

- Construction Machinery

- Appliances construction machinery(8)

- Bolts and Nuts(2)

- Sprocket Segment group(1)

- Hydraulic chpper accumulator(1)

- Komatsu D355 bulldozer ripper(1)

- HPV ROTARY GROUP(1)

- Track Chain(1)

- komatsu front idler(1)

- Piston ring(1)

- Piston(1)

- adapptor(1)

- Injector copper washer(1)

- -(1)

- STEPPER MOTOR(1)

- Pins and Bushings(1)

- Hydraulic Orange Peel Grab(1)

- Uchida(1)

- Supplying construction machinery parts(1)

- HYDAC 20 liter accumulator(1)

- Cylinder Liner Fit(1)

- Rock Bucket(1)

- Jack appliances(1)

- marine gearbox clutch moltiple friction(1)

- chain grease nipples(1)

- NDC Engine Bearing(1)

- Excavator Buckets(1)

- Solenoid(1)

- Operating room equipment

- Laboratory equipment

- Specialized medical equipment

- Dental equipment

- Laser

- Heater, Cooler and Conditioner

- Araz Sanat B500s 500,000 Steel Boiler Room Hot Water Boiler(1)

- Araz Sanat B900s 900,000 Steel Boiler Room Hot Water Boiler(1)

- Araz Sanat B600s 600,000 Steel Boiler Room Hot Water Boiler(1)

- Araz Sanat B700s 700,000 kcal/h Steel Boiler Room Hot Water Boiler(1)

- Araz Sanat B800s 800,000 Steel Boiler Room Hot Water Boiler(1)

- Pipe

- Elevator and Lifting equipments

- Machinery spare parts

- Packing Machines

- Plastic Injection Machine

- Disposable containers(2)

- machinery manufacturing factory pp PVC pet PS to (2)

- Disposable container production machinery(1)

- Plastic sheet production line(1)

- machinery manufacturing factory pp PVC pet PS to (1)

- machinery manufacturing factory pp.PVC.pet.PS to the next (1)

- Plastic PP Disposble CuP Machine(1)

- Plastic Machinery(1)

- -(1)

- machinery manufacturing factory pp.PVC.pet.PS to (1)

- -(1)

- lain pp.PVC.pet.PS (1)

- machinery manufacturing factory pp.PVC.pet.PS to the next (1)

- Plastic Mold(1)

- machinery manufacturing factory pp.PVC.pet.PS to the (1)

- Construction Machinery

- Construction Machinery

- Mining Machinery

- Agriculture & Farming Machinery

- Other industrial Machines

- Water treatment equipment

- Hi-Fi system

- Kitchen Appliances

- Printing Machinert

- Copier

- Packing Machines

- Pump

- Testing Equipment

- Industrial Electrical Equipment

- Air Conditioning Equipment

- Industrial Tools & Parts

- ---(1)

- Brass slotted headless special M8*6 hollow set screws(1)

- 9 mm PVC Conveyor Belt with Polyester Backing(1)

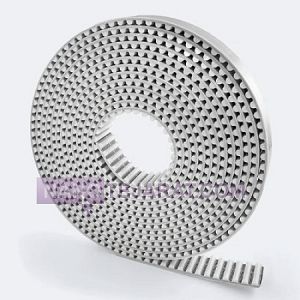

- Megadyne PU welded timing belt RPP5(1)

- 904L hex head bolt machine bolt uns n08904 1.4539 (1)

- Stainless steel 316 special screws knurling custom cold formed fasteners(1)

- 6 mm Double-Layer Rubber Grip Conveyor Belt(1)

- 904L 1.4539 uns n08904 hex tap bolt full thread washers(1)

- Food grade plastic conveyor belt(1)

- Megadyne PU welded timing belt RPP8(1)

- 904L heavy hex bolts uns n08904 stainless steel bolt China(1)

- Megadyne RPP3 Timing Belt(1)

- Megadyne PU welded timing belt RPP14(1)

- Compressors

- Commercial & Trading services

- PVC and UPVC Pipe(2)

- Lead Bar and Lead Oxide Powder(1)

- Sandwich Panel(1)

- Counter(1)

- Safety Valve(1)

- Hex Nut(1)

- Spring Washer Split Washer(1)

- wire rope with polypropylene core PP(1)

- Ceiling Aluminum Tile (1)

- Heater Package(1)

- Polyethylene pipe (1)

- Steel Wire rope(1)

- Faucet (1)

- Carbon steel Pipe(1)

- Wire rope Sling(1)

- Push Fit and Pipe Connections(1)

- Check Valve(1)

- Steel Pipe fittings(1)

- Construction Services

- Machinery Services

- Poultry Equipment

- Cattle & Poultry Drugs

- Fertilizer & Pesticide

- Polymer products

- Glue

- Gas

- Rubber and Plastic

- Chemical Lab Tools

- Mining Machine

- Accurate scales

- Drilling Machine

- Pipe, Fitting and Valve

- Petrochemical

- Antenna

- Phone, Fax and parts

- Transceiver

- Valves

- Polyethylene Female Fitting 1-2x20 (1)

- Polyethylene Reducing Coupling 40x25 mm(1)

- Male Threaded Polyethylene Adapter Size 75 x 2 1-2(1)

- 50 × 32 Polyethylene Reducing Coupling(1)

- Male Threaded Polyethylene Adaptor Size 63x2(1)

- 63x32 Polyethylene Reducing Coupling(1)

- 25x20 mm Polyethylene Reducing Coupling(1)

- Nippon ball valve(1)

- Concrete Pump

- Transportation

- Isolation

- Hoist

- Parquet

- Ceramics and Composites

- Cutting and shaping tools

- THREAD TURNING INSERTS(3)

- THREAD TURNING INSERTS(2)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- -(1)

- -(1)

- pp-13 BEIPING Taiwan(1)

- Pneumatic Tapping Machine(1)

- Measuring supplies(1)

- CNC TAPPING MACHINE(1)

- QUICK CHANGE TAPPING CHUCKS(1)

- QUICK CHANGE TAPPING CHUCKS(1)

- QUICK CHANGE TAPPING CHUCKS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THEREAD PLUG GAUGE(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- Measuring and machining tools(1)

- digital gear tooth calipper(1)

- -(1)

- DRM-20 SITCO (1)

- pp-32N Tools Grinder(1)

- DRILL BIT SHARPENER(1)

- CNC TAPPING MACHINE(1)

- QUICK CHANGE TAPPING CHUCKS(1)

- QUICK CHANGE TAPPING CHUCKS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- TURNING INSERTS(1)

- Diamond-tipped End Mill(1)

- -(1)

- DRILL SHARPENING MACHINE DRM-13(1)

- CNC Tapping Machine TP915 SITCO(1)

- DRILL BIT SHARPENER(1)

- CNC TAPPING MACHINE(1)

- QUICK CHANGE TAPPING CHUCKS(1)

- QUICK CHANGE TAPPING CHUCKS(1)

- Tool Support Type ER Collet(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- -(1)

- -(1)

- Grinder machine pp-30(1)

- CNC Tapping Machine(1)

- pp-13 beiping Drill Bit Sharpener(1)

- CNC TAPPING MACHINE(1)

- CNC TAPPING MACHINE(1)

- QUICK CHANGE TAPPING CHUCKS(1)

- QUICK CHANGE TAPPING CHUCKS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- THREAD TURNING INSERTS(1)

- Security equipment

- Measuring equipment

- Gearbox

- Bearing and belt

PP

| hydraulicmarket |

| Iran |

| 021-55130771 |

chopper combine pump repair

The hydraulic pump of a chopper combine is typically an axial piston or vane type, designed with a flow capacity between 80 and 120 liters per minute. It operates within a working pressure range of 200 to 250 bar and is responsible for supplying hydraulic oil to systems such as lift cylinders, steering, and the feeding mechanism of the cutter. Proper pump type selection and attention to flow capacity are critical to prevent efficiency loss and overheating of the hydraulic oil during harvesting operations.

The installation location of the chopper combine hydraulic pump is usually at the front of the engine, aligned with the power transmission shaft. The connection is often made through direct coupling or flange mounting to ensure mechanical power transfer without energy loss. At this position, high-pressure hoses and return lines to the hydraulic reservoir are attached, requiring precise sealing to prevent leakage and pressure drops. Any shaft misalignment can lead to increased vibration and significantly reduce pump lifespan.

The repair process of the chopper hydraulic pump includes disassembling all components, thoroughly cleaning them, inspecting piston and vane wear, and checking bearing tolerances with 0.01-millimeter accuracy. If scratches or dimensional changes greate

| |

| hydraulicmarket | 021-55130771 |

| hydraulicmarket |

| Iran |

| 021-55130771 |

Casappa hydraulic pump repair

The hydraulic pump of the backhoe loader brand CASAPPA is one of the key components of the hydraulic system, responsible for supplying the required flow and pressure of hydraulic oil. These pumps are usually gear or piston type, with flow capacities ranging from 60 to 120 liters per minute and operating pressures between 180 and 250 bar, providing high efficiency in energy transmission. The precise gear design and optimized sealing system significantly improve performance, reduce leakage, and increase the overall service life of mechanical components.

The main reasons for CASAPPA hydraulic pump failure are oil contamination, cavitation, overload, or high operating temperatures. Early signs of malfunction include pressure drops, unusual noise, and reduced cylinder movement speed. Continued operation with a damaged pump can lead to severe issues in valves and control systems, which drastically increase the overall repair costs. Timely maintenance and oil monitoring are essential to minimize these risks.

Repairing a CASAPPA hydraulic pump typically involves disassembly, inspection of internal wear surfaces, checking seals, and replacing O-rings and bearings. In cases of major damage to gears or pistons, replacement of main components becomes necessary. Repair costs usually ran

| |

| hydraulicmarket | 021-55130771 |

| shoping-14 |

| Iran |

| 02155433645 |

Komatsu D355 bulldozer ripper

The Komatsu D355 bulldozer ripper is made of high-strength steel and is designed to withstand bending stress up to 15,000 N·m and heavy impact loads. The overall length of the ripper is 2.4 meters, and the blade attachment width is 1.2 meters, allowing precise penetration into soil and heavy materials. The ripper is connected to the chassis using steel pins with a diameter of 90 millimeters, capable of bearing static loads up to 20 tons. The hydraulic lift system operates at 300 bar with a flow rate of 180 L/min, providing precise control of the ripper and blade movement. The reinforced and ergonomic design reduces vibration and increases durability under harsh working conditions.

The total weight of the ripper is 1,250 kilograms, allowing easy handling and quick installation on the D355 chassis. Hydraulic cylinders with a diameter of 120 millimeters and a stroke of 450 millimeters ensure smooth and controlled blade movement. A central lubrication system operating at 25 bar prevents premature wear and joint failure. The ripper design allows the blade angle to be adjusted up to 25 degrees in either direction, enabling accurate soil ripping, leveling, and material movement. Its durable and stable performance extends the overall lifespan of the bulldozer system.

| |

| shoping-14 | 02155433645 |

| power-belt |

| Iran |

| 021-22087856 |

Megadyne RPP3 Timing Belt

The Megadyne RPP3 timing belt is manufactured from polychloroprene rubber reinforced with glass fiber cords and coated with nylon fabric, providing excellent tensile strength and abrasion resistance. This belt has a 3-millimeter pitch, and its “Robust Profile” RPP tooth design increases surface contact while minimizing slippage during power transmission. Its tensile strength is measured between 70 and 100 newtons per millimeter of belt width, with a friction coefficient of approximately 0.3. The standard operating temperature range of the Megadyne RPP3 timing belt is from -20 to +100 degrees Celsius, while heat-resistant versions can operate effectively up to 120 degrees.

A key feature of the Megadyne RPP3 timing belt is its high accuracy in synchronization and power transmission with low vibration and reduced noise. It delivers stable performance at speeds up to 9,000 revolutions per minute, with available widths ranging from 9 to 25 millimeters. Standard lengths are produced between 180 and 1500 millimeters, and the curved tooth profile helps reduce stress concentration while extending service life. These specifications make the Megadyne RPP3 timing belt an ideal solution for precision industrial equipment and high-efficiency machinery.

| |

| power-belt | 021-22087856 |

| arya-welding |

| Iran |

| 02166730889 |

Copper Nickel Welding Filler Code ER-CuNi

Copper Nickel Welding Filler is an essential consumable material used in the welding process of copper-nickel alloys, known for its excellent resistance to corrosion, wear, and harsh marine environments. These fillers typically consist of copper and nickel in various ratios commonly 70-30 or 90-10 and provide stable and strong welds due to their thermal expansion coefficient being close to the base metal. Using copper nickel welding filler is highly suitable for joining components in industries such as oil and gas, shipbuilding, and power plants because it maintains mechanical and chemical properties at high temperatures.

From a technical standpoint, these fillers should comply with international standards such as AWS A5.7 or EN ISO 24373 to ensure quality and optimal welding performance. Key parameters in selecting copper nickel welding filler include wire diameter, precise chemical composition, post-weld hardness, and formability. Additionally, excellent corrosion resistance and resistance to thermal cracking make this filler ideal for use in harsh marine and chemical environments. Adhering to technical standards and proper use of these fillers play a crucial role in increasing the longevity and efficiency of welded structures.

| |

| arya-welding | 02166730889 |

| power-belt |

| Iran |

| 021-22087856 |

Megadyne PU welded timing belt RPP14

Megadyne PU welded timing belt RPP14 is manufactured from durable thermoplastic polyurethane reinforced with steel or Kevlar cords, providing high tensile strength and long service life. The belt features a tooth profile with a 14 millimeter pitch, ensuring uniform torque and power transmission in heavy-duty industrial systems and high-load production lines. Its operating temperature ranges from -20 to +100 degrees Celsius, with excellent resistance to wear, oil, and moisture. Standard belt widths typically range from 25 to 115 millimeters, and thermal welding allows production of endless loop belts.

Due to its high dimensional accuracy and precisely engineered tooth design, this belt is ideal for heavy industrial machinery, automated production lines, and precision power transmission systems. The polyurethane compound with a low friction coefficient reduces energy consumption and improves system efficiency. The broad tooth contact surface ensures uniform force distribution and reduces vibration at high speeds. Additionally, customization in belt length and width provides significant flexibility for specialized industrial applications.

| |

| power-belt | 021-22087856 |

| Daghightools- |

| Iran |

| 09123691065 |

Diamond-tipped End Mill

The diamond-coated end mill is a precision tool designed for machining the hardest materials, including ceramics, glass, and tough composites. The overall tool length typically ranges from 80 to 150 millimeters, with shaft diameters from 2 to 12 millimeters. Rotational speeds with 6 bar air pressure or an electric motor reach 20,000 to 40,000 RPM, and motor power usually ranges from 0.2 to 0.6 kilowatts. The tool weighs between 0.5 and 1.2 kilograms to maintain operator control during precise machining and minimize vibration. Ergonomic design and coaxial shaft alignment with accuracy below 0.01 millimeters ensure consistent material removal during long operations.

These end mills feature cutting edges coated with industrial diamond and helix angles ranging from 30 to 45 degrees. The number of cutting edges typically ranges from 2 to 4, enabling material removal without causing cracks. With proper care and lubrication, tool life can exceed 2,500 operational hours. Diamond-coated end mills are manufactured according to ISO 2768 standards and are widely used in aerospace, mold-making, medical, and glass machining industries.

| |

| Daghightools- | 09123691065 |

| power-belt |

| Iran |

| 021-22087856 |

Megadyne PU welded timing belt RPP5

Megadyne PU welded timing belt RPP5 is manufactured from durable thermoplastic polyurethane reinforced with steel or Kevlar cords, providing high tensile strength and long-lasting durability. The belt features a tooth profile with a 5 millimeter pitch, ensuring uniform torque and power transmission in small to medium industrial systems. Its operating temperature range is -20 to +80 degrees Celsius, offering excellent resistance to wear, oil, and moisture. Belt widths typically range from 10 to 50 millimeters, and thermal welding allows the production of customized endless loops.

Due to its precise tooth design and high dimensional accuracy, this belt is ideal for packaging machinery, automated assembly lines, and precision power transmission systems. The polyurethane compound with a low friction coefficient reduces energy consumption and improves system efficiency. The tooth contact surface ensures uniform force distribution and minimizes vibration at high speeds. Customization in belt length and width provides significant flexibility for specialized industrial applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Megadyne PU welded timing belt RPP8

Megadyne PU welded timing belt RPP8 is manufactured from durable thermoplastic polyurethane reinforced with steel or Kevlar cords, providing high tensile strength and long-lasting durability. The belt features a tooth profile with an 8 millimeter pitch, ensuring uniform torque and power transmission in small to medium industrial systems. Its operating temperature range is -20 to +80 degrees Celsius, with excellent resistance to wear, oil, and moisture. Belt widths typically range from 10 to 50 millimeters, and thermal welding enables the production of endless loops.

Due to its precise engineering and high dimensional accuracy, this belt is an ideal solution for packaging machinery, automated assembly lines, and precision power transmission systems. The tooth design ensures uniform force distribution and reduces vibration at high speeds. The polyurethane compound with a low friction coefficient minimizes energy consumption and improves system efficiency. Customization in belt length and width provides significant flexibility for specialized industrial applications.

| |

| power-belt | 021-22087856 |

| shoping-14 |

| Iran |

| 02155433645 |

chain grease nipples

Industrial chain grease nipples are manufactured from alloy steel with chrome or nickel coating to enhance wear and corrosion resistance. Shaft lengths typically range from 20 to 150 millimeters, with inner diameters between 10 and 50 millimeters, designed for temperatures from -20°C to 120°C. Grease capacity reaches up to 50 cc per unit, with working pressure up to 5 bar. NBR or FKM rubber seals prevent dust and water ingress, extending service life beyond 30,000 hours.

Installation on chains uses standard M6 to M12 bolts, with grease entry angles adjustable from 30 to 60 degrees depending on chain type. The lubrication system includes SAE connectors and high-pressure hoses, verified by hydrostatic and dynamic testing for continuous performance. Component design complies with ISO 12100 and DIN 51502 standards, ensuring safety and operational efficiency.

| |

| shoping-14 | 02155433645 |

| shoping-14 |

| Iran |

| 02155433645 |

Supplying construction machinery parts

Supplying construction machinery parts includes gearboxes, oil pumps, hydraulics, chains, and rollers made from alloy steel, gray cast iron, and hardened aluminum. Component lifespan ranges from 3,000 to 20,000 hours, with hydraulic pressure tolerance up to 350 bar and temperature resistance up to 120°C. ISO 9001, DIN 51502, and API 610 standards are applied in design and manufacturing to ensure safety and durability.

The supply process includes incoming quality testing, dimensional and functional inspection, and moisture- and corrosion-resistant packaging. Bearings and connectors are rated for dynamic loads up to 50 tons and operating speeds from 50 to 3,000 rpm. Parts are also coated with hard chrome, nickel, and epoxy paint to resist wear and harsh industrial environments.

| |

| shoping-14 | 02155433645 |

| sayalsanat |

| Iran |

| 021-22087856 |

Nippon ball valve

Nippon ball valve, utilizing advanced Japanese technologies, offers advantages that set it apart from other ball valves:

Long lifespan and high resistance to operational pressures and harsh environmental conditions

Precise sealing that completely prevents leakage even at high temperatures and pressures

Use of high-quality stainless steel and brass materials in the construction, ensuring durability

Smooth and effortless operation when opening and closing the flow of water or other fluids

Standardized design fully compatible with various piping systems and industrial applications

For specialized consultation and pricing on Nippon brand ball valves, contact our experts today!

| |

| sayalsanat | 021-22087856 |

| Iranallexport |

| Iran |

| 021-55421083 |

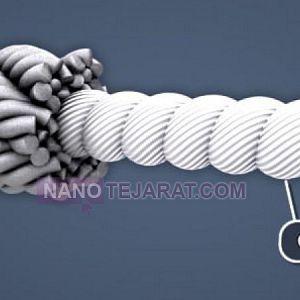

wire rope with polypropylene core PP

The core of wire rope is one of the main components of steel wire rope that plays an important role in determining the type of wire rope and its use.

Around the core of the steel wire rope are strands made up of a number of wires.

Fiber core steel wire ropes are often made of polypropylene, hemp and sisal fibers.

The structure of steel wire ropes with polypropylene core is usually 6 strands or 8 strands.

PP core steel wire ropes are mostly used in marine industries and are very suitable for marine uses due to lack of water absorption and weight gain and are also suitable for floating use on water.

In general, steel wire ropes with plastic cores weigh less than others.

| |

| Iranallexport | 021-55421083 |

| akhavan-wire-rope |

| Iran |

| 021-55411976 |

PP marine rope

Marine rope is produced from polymer compounds to have proper resistance in contact with corrosive substances in sea water that are in the form of various minerals and salts. The most widely used polymer compounds in the production of marine rope are polypropylene PP, which has very low affinity due to its heavy molecules and does not corrode when in contact with salty sea water. Another reason for using polypropylene ropes in marine applications is the lower density of these compounds compared to sea water. This causes the sea ropes to be placed on the surface of the water and visually lead to a better view and not get caught among the propellers of ships and lanyards.

| |

| akhavan-wire-rope | 021-55411976 |

| federal-wire-rope |

| Iran |

| 021-55429480 |

PP marine ropes

PP marine ropes are strong type of rope that is used as replacement for steel wire rope and chain due to much higher resistance against salt water. marine ropes are not only made of PP and synthetic materials but also a very common, strong and resistant type of marine rope is Manila rope that comes mostly from Philippines and therefore has the name taken after the capital city of this country. PP marine ropes are highly flexible and do not pick extra weight once exposed to sea water.

| |

| federal-wire-rope | 021-55429480 |

| hamoonsanat |

| Iran |

| 09902245921 |

Tapping Machine with Clutch

A tapping machine equipped with a mechanical or automatic clutch system to prevent tap breakage when excessive resistance is encountered. This feature improves safety, tool life, and accuracy, especially when working with hard or delicate materials.

| |

| hamoonsanat | 09902245921 |