- Pneumatic tools

- Hydraulic tools

- Welding and Soldering

- Steel Wire rope and accessories

- Steel Wire Ropes(3)

- G120 master link(2)

- Stainless steel 316 Wire Rope 4 mm(1)

- Stainless steel 316 Wire Rope 8 mm(1)

- Wire Rope 6X37 IWRC(1)

- 6*37 steel wire rope sling(1)

- 1*19 steel wire rope(1)

- 6*19W+IWR hoisting steel wire rope(1)

- Eyehook(1)

- Stainless steel Wire Rope 3 mm(1)

- Stainless steel 316 Wire Rope(1)

- Galvanized Steel Wire Rope(1)

- 8*19s-8.0 steel wire rope(1)

- 6*37S+IWR wire rope(1)

- verosteel 8(1)

- Steel Wire RopeUngalvanized and Galvanized(1)

- Stainless steel 316 Wire Rope 2 mm(1)

- Crane Wire Rope(1)

- construction winch(1)

- 19*7-20.0 non-rotating galvanized steel wire rope(1)

- 6*19S+FC wire rope(1)

- Stainless steel 316 Wire Rope 5 mm(1)

- Stainless steel 316 Wire Rope 6 mm(1)

- Wire Rope 6X19 IWRC(1)

- 18*7-14.0 steel wire rope(1)

- 6*36SW+IWRC steel wire rope(1)

- STEEL WIRE ROPE SLINGS(1)

- Spring

- Car

- Truck and minitruck

- Construction Machinery

- Spare parts for construction machinery(47)

- Appliances construction machinery(8)

- Nail construction machinery(6)

- construction machinery spare parts(6)

- hydraulic pump for construction machinery(6)

- Chain construction machinery(5)

- chinese construction machinery wheel loaders caliper kits(4)

- Construction machinery engine components(4)

- motor parts of construction machinery(3)

- construction machinery filters(3)

- construction machinery spare parts(3)

- construction machinery filter(2)

- construction machinery mann(2)

- construction machinery cutting edge(2)

- construction machinery filters(2)

- construction machinery filter(1)

- construction machinery spare parts(1)

- construction machinery filters(1)

- construction machinery spare parts(1)

- construction machinery cutting edge(1)

- construction machinery filter(1)

- construction machinery spare parts(1)

- construction machinery chain(1)

- construction machinery spare parts(1)

- construction machinery spare parts(1)

- construction machinery under carriage(1)

- Construction machinery sunroofs(1)

- Industrial, construction, and agricultural hydraulic pumps(1)

- ITR construction machinery sprocket(1)

- Construction spare parts(1)

- Bolts and Nuts(1)

- Chinese construction machinery(1)

- komatsu construction machinery spare parts(1)

- construction machinery spare parts(1)

- construction machinery spare parts(1)

- construction machinery wheel(1)

- construction machinery spare parts(1)

- construction machinery cutting edge(1)

- SDLG construction machinery(1)

- construction machinery spare parts(1)

- CONSTRUCTION MACHINERY SPARE PARTS(1)

- Construction machinery accumulator(1)

- Supplying construction machinery parts(1)

- Construction machinery bearings(1)

- Track Chain without Shoes for Construction Machinery(1)

- undercarriage(1)

- Sprocket(1)

- Spare parts for construction machinery(1)

- construction machinery spare parts(1)

- construction machinery spare parts(1)

- construction machinery spare parts(1)

- construction machinery spare parts(1)

- construction machinery cutting edge(1)

- construction machinery filter(1)

- construction machinery engine parts(1)

- construction machinery spare parts(1)

- Chinese construction machinery spare parts(1)

- construction machinery spare parts(1)

- Types of superchargers for construction machinery: loaders, bulldozers, graders, and excavators(1)

- Construction machinery accumulator(1)

- Track Chain(1)

- construction machinary engine part(1)

- construction machinery spare parts(1)

- construction machinery spare parts(1)

- construction machinery spare parts(1)

- construction machinery spare parts(1)

- construction machinery roller(1)

- construction machinery filter(1)

- construction machinery spare parts(1)

- construction machinery spare parts(1)

- construction machinery spare parts(1)

- construction machinery(1)

- Spare Part For Construction Machinery(1)

- Construction machinery chains(1)

- ITR Construction Machinery Fork(1)

- Carrier Roller(1)

- construction machinary spare part(1)

- Engine parts for construction machinery(1)

- Construction Services

- Doors and Windows

- Faucet

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction valves(1)

- Construction Materials

- Construction Machinery

- Construction Machinery

- Mining Machinery

- Industrial Tools & Parts

- Compressors

- Electric Services

- Commercial & Trading services

- Packing & Printing Services

- Mining Machine

- Housing Equipment

- Isolation

- Refurbishment

- Booth Making

- Spatial Design

Construction

Search Results For Construction| shoping-14 |

| Iran |

| 02155433645 |

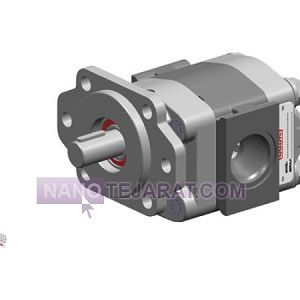

construction hydraulic pump

The hydraulic pump for construction machinery is designed to generate stable pressure and accurately transfer hydraulic power within the motion systems of heavy equipment. It is an axial piston type featuring a swash plate mechanism with an automatic pressure control system. The displacement range is between 68 and 185 cubic centimeters per revolution, with a rated working pressure up to 340 bar. The housing is made of ductile cast iron GGG45 with a compressive strength of 370 MPa. The inner cylinder surface is reinforced with a 20–25 micron hard chrome layer to minimize wear. It operates reliably between -25°C and +115°C and is built for heavy-duty conditions.

Hydraulic pumps used in construction equipment achieve overall efficiency above 95 percent and utilize optimized flow channels to reduce pressure losses. The input shaft is made of 34CrNiMo6 alloy steel, heat-treated for superior fatigue and torque resistance. The sealing system includes FKM O-rings capable of withstanding high temperatures and pressures up to 400 bar. Tapered roller bearings with a 45 kN radial load capacity ensure mechanical stability and service life exceeding 14,000 hours. These features make the pump an ideal choice for loaders, excavators, and graders.

| |

| shoping-14 | 02155433645 |

| shoping-14 |

| Iran |

| 02155433645 |

Construction machinery engine components

Engine components in construction machinery, including pistons, rings, connecting rod bushings, crankshafts, and hydraulic pumps, are manufactured from alloy steel and high-strength aluminum to withstand cylinder pressures up to 25 MPa and operating temperatures up to 300 degrees Celsius. Dimensions and tolerances are CNC-controlled, with surface finishing precision up to 0.01 millimeters. Contact surfaces are reinforced with wear-resistant coatings, nitriding, and hardening to ensure a service life exceeding 12,000 operating hours. Friction coefficients between contacting surfaces range from 0.08 to 0.12, and components can sustain instantaneous loads up to 2000 Nm.

In the design of construction machinery engine components, oil pathways and cooling channels are optimized to provide uniform lubrication and rapid heat dissipation. Components are engineered to resist vibrations, shocks, and thermal stresses, with thermal deformation under 0.05 millimeters. Weight varies from 0.2 to 35 kilograms depending on function, allowing direct installation on the engine block and chassis with standard bolts and shafts. Reliable operation is ensured within a temperature range of -20 to 300 degrees Celsius, maintaining optimal engine performance.

| |

| shoping-14 | 02155433645 |

| shoping-14 |

| Iran |

| 02155433645 |

construction hydraulic pump

The construction hydraulic pump is designed to provide consistent hydraulic power for heavy-duty equipment such as excavators, loaders, and graders. It features an axial piston mechanism with a swash plate configuration and a displacement range between 50 and 185 cubic centimeters per revolution. The standard operating pressure is 300 bar, while peak pressure capacity reaches up to 420 bar. The pump housing is made of compact aluminum alloy with a 20–30 micron hard chrome coating for enhanced wear resistance. It operates reliably across temperatures from -30°C to +115°C under fluctuating thermal conditions.

Construction hydraulic pumps achieve over 94 percent volumetric efficiency with a straight-flow design that reduces energy losses. The main shaft is made from fatigue-resistant alloy steel treated by nitrocarburization for surface strength. The sealing system includes FKM O-rings capable of withstanding 380 bar pressure and 200°C temperature. Tapered roller bearings with a 45 kN radial load capacity extend operational life beyond 13,000 hours. This configuration ensures stable operation, lower energy consumption, and improved hydraulic performance in demanding construction environments.

| |

| shoping-14 | 02155433645 |

| shoping-14 |

| Iran |

| 02155433645 |

construction hydraulic pump

The hydraulic pump for construction machinery is designed to provide a consistent flow of pressurized oil in motion and control circuits of heavy-duty equipment. It is an axial piston type featuring a swash plate design and variable flow control system. The displacement capacity ranges from 70 to 190 cubic centimeters per revolution, with a continuous working pressure up to 330 bar. The housing is made of ductile cast iron GGG40 with a compressive strength of 350 MPa. The internal cylinder is coated with 25-micron hard nickel to enhance wear resistance and extend service life. The operating temperature range is from -30°C to +120°C.

Construction hydraulic pumps are manufactured with over 94 percent volumetric efficiency and straight-flow design to minimize energy losses. The input shaft is made from alloy steel treated with a nitriding process for high fatigue resistance. The sealing system utilizes FKM O-rings capable of withstanding 380 bar pressure and 200°C temperature. Roller bearings with a 43 kN radial load capacity ensure stable performance and service life exceeding 13,000 hours. These pumps deliver reliable and durable performance in loaders, bulldozers, and excavators.

| |

| shoping-14 | 02155433645 |

| shoping-14 |

| Iran |

| 02155433645 |

hydraulic pump for construction machinery

The hydraulic pump for construction machinery is designed to provide steady flow and high pressure in the control and motion circuits of heavy-duty equipment. It is an axial piston pump with a swash plate and internal pressure compensation mechanism. The displacement per revolution ranges from 70 to 200 cubic centimeters, with continuous operating pressure up to 350 bar. The housing is made of ductile cast iron GGG50 with a tensile strength of 500 MPa. The inner cylinder surface is coated with 25-micron hard nickel to enhance wear resistance. The pump maintains stable efficiency in temperatures from -30°C to +120°C under heavy-duty conditions.

Hydraulic pumps for construction equipment are manufactured with over 94 percent volumetric efficiency and a precisely engineered lubrication system. The drive shaft is made from 42CrMo4 alloy steel with deep heat treatment for high torsional strength. The sealing system uses FKM O-rings resistant to 400 bar pressure and 200°C temperature. Tapered roller bearings with a 45 kN radial load capacity extend service life beyond 13,000 hours. These pumps deliver reliable and continuous power transmission in excavators, loaders, and graders.

| |

| shoping-14 | 02155433645 |

| shoping-14 |

| Iran |

| 02155433645 |

Construction machinery engine components

Construction machinery engine components include pistons, rings, connecting rod bushings, crankshafts, and hydraulic pumps, manufactured from alloy steel and high-strength aluminum to withstand cylinder pressures up to 25 MPa and operating temperatures up to 300 degrees Celsius. Dimensions and tolerances are CNC-controlled, with surface finishing precision up to 0.01 millimeters. Contact surfaces are enhanced with nitriding, wear-resistant coatings, and hardening to ensure component life up to 12,000 operating hours. Friction coefficients between contacting surfaces range from 0.08 to 0.12, and components can endure instantaneous loads up to 2000 Nm.

In the design of these components, oil flow and cooling channels are optimized to guarantee uniform heat transfer and lubrication. Mechanical resistance against vibrations, shock loads, and thermal stresses is ensured, with thermal deformation below 0.05 millimeters. Component weight varies from 0.2 to 35 kilograms depending on the application, allowing direct installation on the chassis and engine block using standard bolts and shafts. Stable operation is guaranteed within a temperature range of -20 to 300 degrees Celsius.

| |

| shoping-14 | 02155433645 |

| shoping-14 |

| Iran |

| 02155433645 |

Construction machinery engine components

Engine components in construction machinery, including pistons, rings, connecting rod bushings, crankshafts, and hydraulic pumps, are made from alloy steel and high-strength aluminum to withstand cylinder pressures up to 25 MPa and operating temperatures up to 300 degrees Celsius. Dimensions and tolerances are CNC-controlled, with surface finishing precision up to 0.01 millimeters. Contact surfaces are reinforced with nitriding, hardening, and wear-resistant coatings to ensure a service life exceeding 12,000 operating hours. Friction coefficients range from 0.08 to 0.12, and components can endure instantaneous loads up to 2000 Nm.

Oil pathways and cooling channels are optimized to provide uniform lubrication and efficient heat dissipation. Components are engineered to resist vibrations, shocks, and thermal stresses, with thermal deformation below 0.05 millimeters. Component weight varies between 0.2 to 35 kilograms depending on application, and installation is direct on the chassis and engine block using standard bolts and shafts. Reliable operation is guaranteed within a temperature range of -20 to 300 degrees Celsius, maintaining optimal engine performance.

| |

| shoping-14 | 02155433645 |

| shoping-14 |

| Iran |

| 02155433645 |

construction hydraulic pump

The hydraulic pump for construction machinery is designed to provide the required hydraulic power for steering, lifting, and power transmission systems. It is an axial piston type with a swash plate and automatic pressure compensation mechanism. The displacement capacity ranges from 65 to 200 cubic centimeters per revolution, with a continuous operating pressure of 320 bar. The housing is made of ductile cast iron GGG50 with a tensile strength of 500 MPa. The inner cylinder surface is coated with 30-micron hard chrome to improve wear resistance. The operating temperature range is from -25°C to +115°C, and overall efficiency exceeds 93 percent.

Hydraulic pumps for construction equipment are equipped with roller bearings supporting a 45 kN radial load capacity. The input shaft is made from hardened 42CrMo4 alloy steel for superior mechanical strength. The sealing system uses FKM O-rings resistant to pressures up to 400 bar and ISO VG 46 hydraulic oils. The 30-degree angled input shaft minimizes vibration and mechanical oscillation. These pumps deliver continuous operation up to 13,000 hours and are widely used in excavators, loaders, and bulldozers.

| |

| shoping-14 | 02155433645 |

| shoping-14 |

| Iran |

| 02155433645 |

Construction engine components

Construction engine components include pistons, rings, connecting rod bushings, crankshafts, and hydraulic pumps made from alloy steel and high-strength aluminum to withstand cylinder pressures up to 25 MPa and operating temperatures up to 300 degrees Celsius. Dimensions and tolerances are CNC-controlled, with surface precision measured up to 0.01 millimeters. All components are reinforced with heat treatment, nitriding, and wear-resistant coatings, ensuring service life up to 12,000 operating hours. The friction coefficient between contact surfaces is maintained between 0.08 and 0.12, and instantaneous load capacity reaches 2000 Nm.

In the design of construction engine components, oil flow and cooling pathways are engineered to ensure optimal heat transfer and lubrication. Mechanical resistance to instantaneous shocks and severe vibrations is guaranteed, with thermal deformation below 0.05 millimeters. Component weight varies from 0.2 to 35 kilograms depending on application, allowing direct installation on the engine block and chassis using standard bolts and shafts. Stable operation within -20 to 300 degrees Celsius is ensured.

| |

| shoping-14 | 02155433645 |

| Rahsaz-market |

| Iran |

| 02155433645 |

ITR construction machinery sprocket

The ITR construction machinery sprocket is engineered to transfer power and motion to the track in heavy machinery drive systems. It is made of hardened alloy steel with tensile strength of 1000 MPa and surface hardness of 45-50 HRC. The internal diameter is designed to fit the machine shaft, with tolerances below 0.02 mm ensuring precise installation and slip-free rotation. Teeth surfaces are wear-resistant and coated against corrosion, providing a service life of up to 5000 operating hours under heavy-duty conditions. The sprocket design ensures uniform force distribution on the track while reducing friction.

The ITR sprocket can withstand dynamic loads up to 15 tons and offers high fatigue resistance. Each sprocket weighs approximately 35 kilograms and is installed using corrosion-resistant bolts and precise tolerances. Industrial bearings with high radial and axial load capacity ensure smooth operation and reduced system vibration. All components are manufactured according to ISO 6336 and ASTM A572 standards, ensuring durability and consistent performance of construction machinery under heavy-duty operating conditions.

| |

| Rahsaz-market | 02155433645 |

| shoping-14 |

| Iran |

| 02155433645 |

Industrial, construction, and agricultural hydraulic pumps

Industrial, construction, and agricultural hydraulic pumps are designed to deliver consistent oil pressure and flow in heavy-duty hydraulic systems. The pump housing is made of compacted graphite cast iron GGG40 with compressive strength up to 350 MPa. The main shaft is alloy steel 42CrMo4 with surface hardness between 58 and 62 HRC. Displacement ranges from 25 to 160 cubic centimeters per revolution, with operating speeds between 500 and 2800 rpm. The sealing system uses NBR O-rings resistant to 120°C and pressures up to 320 bar.

Industrial and agricultural hydraulic pumps are produced in gear and piston types with volumetric efficiency above 92 percent. Output flow varies by model from 10 to 240 liters per minute. Precision needle bearings and a dynamically balanced rotor reduce vibration and extend service life beyond 10,000 hours. Inlet and outlet ports use SAE fittings ranging from ½ to 1¼ inches. This design ensures stable operation, minimizes energy losses, and enhances hydraulic system efficiency in construction machinery and agricultural equipment.

| |

| shoping-14 | 02155433645 |

| shoping-14 |

| Iran |

| 02155433645 |

construction hydraulic pump

The construction hydraulic pump is engineered to deliver high pressure and stable flow in heavy machinery control and power transmission systems. It is an axial piston type with a swash plate design, offering a displacement capacity between 45 and 180 cubic centimeters per revolution. Operating pressure ranges from 250 to 350 bar, with a peak pressure tolerance up to 420 bar. The housing is made of cast aluminum alloy with a 25-micron hard nickel inner coating for wear resistance. The operating temperature range is from -25°C to +110°C.

Construction hydraulic pumps feature over 93 percent volumetric efficiency and optimized flow paths to minimize pressure loss. The input shaft is made of hardened 16MnCr5 steel with heat treatment for durability. Sealing is achieved with FKM O-rings resistant to mineral oils and pressures up to 400 bar. Roller bearings with a 40 kN radial load capacity extend pump life beyond 12,000 hours. These properties ensure reliable and continuous performance in excavators, loaders, and bulldozers.

| |

| shoping-14 | 02155433645 |

| Rahsaz-market |

| Iran |

| 02155433645 |

Track Chain without Shoes for Construction Machinery

The ITR track chain without shoes is engineered for power and motion transmission in excavator and bulldozer track systems. It is made of hardened alloy steel with tensile strength up to 1000 MPa, and the internal teeth are surface-hardened to 45-50 HRC for high wear and pressure resistance. The pitch ranges from 160 to 200 mm, and pin thickness is approximately 50 mm, ensuring stability and long-term durability. All joints are manufactured with tolerances below 0.05 mm to provide smooth, slip-free operation in the system.

The ITR track chain without shoes offers high fatigue resistance and can withstand dynamic loads up to 20 tons, operating in temperatures from -30°C to +80°C. Each meter of chain weighs approximately 75 kilograms, and the tooth design distributes forces evenly, reducing point pressure on shafts and wheels. All components are produced according to ISO 13565 and ASTM A572 standards, ensuring durability and consistent performance of the tracked system.

| |

| Rahsaz-market | 02155433645 |

| Rahsaz-market |

| Iran |

| 02155433645 |

ITR Construction Machinery Fork

The ITR construction machinery fork is engineered for handling and stabilizing heavy loads in construction and mining equipment. It is made of hardened alloy steel with tensile strength up to 950 MPa and a wear- and corrosion-resistant surface of 40-45 HRC. The fork arms are approximately 1200 mm long with a total width of 400 mm, ensuring stability and uniform load distribution. The chassis attachment design with tolerances below 0.05 mm allows quick and secure installation, preventing slippage and unwanted movement.

The ITR fork offers high fatigue resistance and can withstand dynamic loads up to 10 tons, operating in temperatures from -30°C to +80°C. The total weight is around 85 kilograms, and the load contact surface is designed with precise curvature to reduce point pressure. All components are manufactured according to ISO 1052 and ASTM A36 standards, ensuring durability, safety, and consistent performance under heavy-duty operating conditions.

| |

| Rahsaz-market | 02155433645 |

| shoping-14 |

| Iran |

| 02155433645 |

Types of superchargers for construction machinery: loaders, bulldozers, graders, and excavators

Superchargers for construction machinery include mechanical types Roots and Twin-Screw and turbochargers positive pressure to increase engine intake air volume. Operating pressure ranges from 0.5 to 2.5 bar, with outlet air temperatures up to 150°C. Airflow capacity varies between 500 to 5000 liters per minute depending on engine and machine type. Shafts and rotors are made of alloy steel with 55–60 HRC hardness, with maximum RPM up to 20,000 for turbos and 6,000 for mechanical superchargers.

Superchargers are equipped with double-sided bearings, high-pressure lubrication, and oil/air cooling systems to maintain engine temperature. Installation and tuning follow ISO 9001 and SAE J726 standards to ensure accurate air pressure and volume across all engine speeds. Components feature aluminum or hard chrome coating for wear and corrosion resistance, with a service life of up to 10,000 hours under industrial conditions.

| |

| shoping-14 | 02155433645 |

| shoping-14 |

| Iran |

| 02155433645 |

Construction machinery chains

Construction machinery chains are typically made of heat-treated alloy steel with surface chrome plating to enhance wear, fatigue, and corrosion resistance. Chain widths range from 150 to 700 millimeters, with lengths from 1 to 10 meters depending on the equipment type. Dynamic load capacity per link ranges from 5 to 50 tons, and operating temperature is designed from -20°C to 120°C. Rollers and pins have 50 to 60 HRC hardness and are pre-lubricated with grease under pressure up to 5 bar.

Chains undergo precise dimensional and functional inspection, with epoxy or nickel anti-corrosion coating for harsh industrial and soil environments. Pin spacing and link pitch are designed according to ISO 1677 and DIN 8165 standards. Chain installation and tensioning are performed with hydraulic or mechanical tools, ensuring a service life exceeding 20,000 hours.

| |

| shoping-14 | 02155433645 |

| mana-filter |

| Iran |

| 021-55425679 |

Construction machinery hydraulic filter

There are various hydraulic and pneumatic sections within the construction machines. hydraulic filters are used on the hydraulic pass to filter and eliminate splinters and contamination of hydraulic oil or other hydraulic fluid and help maintain and increase the durability of hydraulic system parts. hydraulic jacks are one of the hydraulic systems of construction machines that require hydraulic filters. in some specific cases if the oil filter has the same flow rate, pressure and capacity to remove hazardous contamination from the hydraulic flow can be used instead of hydraulic filter. However, since construction machines bear very high levels of pressure within the hydraulic system it is recommended to use high quality hydraulic filters with international brands such as DONALDSON, FLEETGUARD, MANN, SAKURA, BALDWIN , ...

| |

| mana-filter | 021-55425679 |

| mana-filter |

| Iran |

| 021-55425679 |

Construction machinery separator filter

Various kinds and brands of separator filters are used on construction machines such as excavators, wheel loaders, bulldozers, dump trucks and Bobcat mini loaders. construction machines diesel engines should generate very high power and torque and therefore using separator filters to enhance the quality of gas-oil prior to being injected into the engine chambers could help increase the external torque substantially. the advantage of using separator filters on construction machines as opposed to fuel filters is that fuel filters are basically unable to remove unwanted liquid particles such as water drops that lessens the potential of gas-oil. the most well-known manufacturers of separator filters are Donaldson, Mann which is used by default on DEUTZ engines, Fleetguard that is used as OE part on Cummins diesel engines.

| |

| mana-filter | 021-55425679 |

| shoping-14 |

| Iran |

| 02155433645 |

Supplying construction machinery parts

Supplying construction machinery parts includes gearboxes, oil pumps, hydraulics, chains, and rollers made from alloy steel, gray cast iron, and hardened aluminum. Component lifespan ranges from 3,000 to 20,000 hours, with hydraulic pressure tolerance up to 350 bar and temperature resistance up to 120°C. ISO 9001, DIN 51502, and API 610 standards are applied in design and manufacturing to ensure safety and durability.

The supply process includes incoming quality testing, dimensional and functional inspection, and moisture- and corrosion-resistant packaging. Bearings and connectors are rated for dynamic loads up to 50 tons and operating speeds from 50 to 3,000 rpm. Parts are also coated with hard chrome, nickel, and epoxy paint to resist wear and harsh industrial environments.

| |

| shoping-14 | 02155433645 |

| shoping-14 |

| Iran |

| 02155433645 |

Construction machinery sunroofs

Construction machinery sunroofs are typically made of tempered glass 8 to 12 millimeters thick, with corrosion-resistant steel or aluminum frames. Standard dimensions range from 500×500 to 1200×1000 millimeters, with wind pressure resistance up to 1200 Pascal and ambient temperature tolerance up to 80°C. The opening and closing system uses a 12 or 24-volt electric motor with worm gear and movement speed of 5 to 10 millimeters per second.

The mechanism includes steel rails and rollers with nickel coating and initial lubrication for smooth, wear-free operation. EPDM sealing prevents dust and water ingress into the cabin, with a service life of over 50,000 open-close cycles. Sunroof design complies with ISO 12100 and construction machinery safety standards.

| |

| shoping-14 | 02155433645 |

| mana-filter |

| Iran |

| 021-55425679 |

Construction machinery fuel filter

Fuel filter that is used in construction machines to purify the gas oil that feeds the diesel engines such as Cummins play a very important role in higher durability of engines parts since gas oil use high levels of contamination , fume and sands once being pumped from the tanks. Construction machinery fuel filter should be monitored and replaced on regular basis in order to have a better combustion within the engines, prevent the valves from being clogged and better maintain engine parts. fuel filter is produced in various size for construction machines depending on the working capacity of the engine and the cylinder volume. some of the well-known manufacturers of fuel filter for construction machines are Donaldson, Fleetguard, Mann.

| |

| mana-filter | 021-55425679 |

| mana-filter |

| Iran |

| 021-55425679 |

Oil filter for construction machines

Oil filter is one of the most important filters among all the various filters used on construction machinery. oil filter that is placed on the path of oil circulation the engine for lubrication and heat transfer absorbs all the contamination within the oil that is generated in the engine due to gas oil combustion and due to abrasion of cylinder liner and piston. oil filters have some specification codes such as 50% - 10 which defines the 50% efficiency of oil filter in absorbing particles with 10 micro meter dimensions. There are many well-known manufacturers of construction machinery oil filters including DONALDSON, FLEETGUARD, WIX, MANN, and BALDWIN.

| |

| mana-filter | 021-55425679 |

| mana-filter |

| Iran |

| 021-55425679 |

Construction machinery engine air filter

Construction machinery air filter that is used most often in cylindrical shape has a very important role to enhance the combustion and performance of diesel engines but purifying the air and help maintain and increase the life time of engine parts. considering the working condition of construction machines including wheel loaders, excavators and bulldozers that are widely exposed to high levels of dust and contamination using engine are filter also known as intake air filter sounds paramount. the internal media of most intake air filters is cellulose and in some specific cases flame resistant cellulose.

| |

| mana-filter | 021-55425679 |

| mana-filter |

| Iran |

| 021-55425679 |

Construction machine cabin filter

Construction machines usually deal with high degree of air contamination due to their application to move and load dust. therefore, using high quality cabin air filter is mandatory in order to eliminate dust and other contamination from the air blowing in the the cabin. most construction machine air filters are square shape and are made of cellulose.

| |

| mana-filter | 021-55425679 |