| kariz-industrial-equipment |

| Iran |

| 021-55400161 |

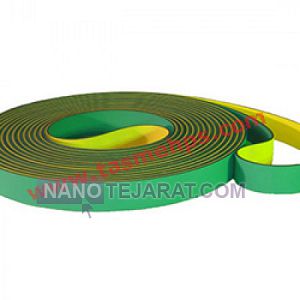

Sale of silk cargo belts in different tonnages and widths

Flat silk carrying belt for sale

Sale of round silk carrying belt

Along with steel rope tow wire, chain, crane, silk cargo belt is one of the most important equipment for lifting and moving goods.

These types of belts, which are produced by interweaving polyester threads, can be supplied in different widths and tonnages according to the needs and uses, and made in Germany, Korea, Turkey, China and Iran.

The most important features of this type of belts, in addition to high load bearing capacity, are anti-wear, flexibility, and the important feature of not damaging the cargo and goods in question.

Silk carrying belt / mane / with a carrying capacity of 2 tons / width 5 cm

Silk cargo belt / supersuboho / with a carrying capacity of 2 tons / width of 5 cm

Silk cargo belt / Elephant / with a carrying capacity of 2 tons / width of 5 cm

Silk carrying belt / mane / with a carrying capacity of 3 tons / width 7.5 cm

Silk cargo belt / Supersuboho / with a carrying capacity of 3 tons / width 7.5 cm

Silk cargo belt / Elephant / with a carrying capacity of 3 tons / width 7.5 cm

Silk cargo belt / mane / with a carrying capacity of 4 tons / width 10 cm

Silk cargo belt / Supersuboho / with a carrying capacity of 4 ton

| |

| kariz-industrial-equipment | 021-55400161 |

| kariz-industrial-equipment |

| Iran |

| 021-55400161 |

Import, production and distribution of load restraint ratchet straps in Kariz industrial equipment.

Sale of ratchet straps

Sale of load restraint belts

Sale of 1 ton ratchet belt

2 ton ratchet belt for sale

5 ton ratchet belt for sale

10 ton ratchet belt for sale

Sale of 5 cm wide ratchet strap

Sale of 7 cm wide ratchet strap

Sale of 7.5 cm wide ratchet strap

Sale of 10 cm wide ratchet strap

10 meter long ratchet strap for sale

Sale of military ratchet straps

Turkish ratchet belt sale

Sale of Chinese ratchet straps

Sale of Iranian ratchet straps

Selling polyester ratchet straps

The ratchet belt or the ratchet load belt is a load belt family, because this load belt does not have the ability to bear the load and can only ensure the safety of the load during the transfer operation. The ratchet belt is used only for load restraint. Not in cargo transportation. Ratchet belts are mostly used in vans, trucks, trailers, off-road vehicles, and for fixing and restraining loads on pallets.

Cargo belts consist of two parts: belt and ratchet, the belt has the task of closing and holding the load, and the ratchet has the task of fixing and securing the ratchet. This type of ratchet belt is made of polyester. Polyester for its structural features It is a good option for pe

| |

| kariz-industrial-equipment | 021-55400161 |

| kariz-industrial-equipment |

| Iran |

| 021-55400161 |

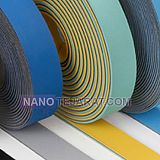

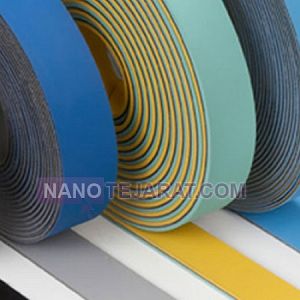

Import and distribution of 5 cm wide 2 ton polyester conveyor belts in Kariz industrial equipment.

Sale of cargo belts

Sale of loading belts

Selling polyester belts

Sale of silk cargo belts

Flat silk carrying belt for sale

Sale of round silk carrying belt

Sale of Yalle cargo belts

Sale of Elephant cargo belt

Sale of Super SUHBO cargo belt

Selling Carl Stahl cargo belts

Sale of strength carrying belts

Selling Korean cargo belts

Selling German cargo belts

Selling Chinese cargo belts

Along with steel rope tow wire, chain, crane, silk cargo belt is one of the most important equipment for lifting and moving goods.

These types of belts, which are produced by interweaving polyester threads, can be supplied in different widths and tonnages according to the needs and uses, and made in Germany, Korea, Turkey, China and Iran.

The most important features of this type of belts, in addition to high load bearing capacity, are anti-wear, flexibility, and the important feature of not damaging the cargo and goods in question.

5 cm double silk carrying strap 2 tons 1 meter Elephant Korea

5 cm double silk cargo belt 2 tons 2 meters Elephant Korea

5 cm double silk cargo belt 2 tons 3 meters Elephant Korea

5 cm double silk cargo belt 2 tons 4 meters Elephant Korea

Double 5

| |

| kariz-industrial-equipment | 021-55400161 |

| kariz-industrial-equipment |

| Iran |

| 021-55400161 |

Import and distribution of 5 cm wide 2 ton polyester conveyor belts in Kariz industrial equipment.

Sale of cargo belts

Sale of loading belts

Selling polyester belts

Sale of silk cargo belts

Flat silk carrying belt for sale

Sale of round silk carrying belt

Sale of Yalle cargo belts

Sale of Elephant cargo belt

Sale of Super SUHBO cargo belt

Selling Carl Stahl cargo belts

Sale of strength carrying belts

Selling Korean cargo belts

Selling German cargo belts

Selling Chinese cargo belts

Along with steel rope tow wire, chain, crane, silk cargo belt is one of the most important equipment for lifting and moving goods.

These types of belts, which are produced by interweaving polyester threads, can be supplied in different widths and tonnages according to the needs and uses, and made in Germany, Korea, Turkey, China and Iran.

The most important features of this type of belts, in addition to high load bearing capacity, are anti-wear, flexibility, and the important feature of not damaging the cargo and goods in question.

5 cm double silk carrying strap 2 tons 1 meter Elephant Korea

5 cm double silk cargo belt 2 tons 2 meters Elephant Korea

5 cm double silk cargo belt 2 tons 3 meters Elephant Korea

5 cm double silk cargo belt 2 tons 4 meters Elephant Korea

Double 5

| |

| kariz-industrial-equipment | 021-55400161 |

| kariz-industrial-equipment |

| Iran |

| 021-55400161 |

Import and distribution of 5 cm wide 2 ton polyester conveyor belts in Kariz industrial equipment.

Sale of cargo belts

Sale of loading belts

Selling polyester belts

Sale of silk cargo belts

Flat silk carrying belt for sale

Sale of round silk carrying belt

Sale of Yalle cargo belts

Sale of Elephant cargo belt

Sale of Super SUHBO cargo belt

Selling Carl Stahl cargo belts

Sale of strength carrying belts

Selling Korean cargo belts

Selling German cargo belts

Selling Chinese cargo belts

Along with steel rope tow wire, chain, crane, silk cargo belt is one of the most important equipment for lifting and moving goods.

These types of belts, which are produced by interweaving polyester threads, can be supplied in different widths and tonnages according to the needs and uses, and made in Germany, Korea, Turkey, China and Iran.

The most important features of this type of belts, in addition to high load bearing capacity, are anti-wear, flexibility, and the important feature of not damaging the cargo and goods in question.

5 cm double silk carrying strap 2 tons 1 meter Elephant Korea

5 cm double silk cargo belt 2 tons 2 meters Elephant Korea

5 cm double silk cargo belt 2 tons 3 meters Elephant Korea

5 cm double silk cargo belt 2 tons 4 meters Elephant Korea

Double 5

| |

| kariz-industrial-equipment | 021-55400161 |

| kariz-industrial-equipment |

| Iran |

| 021-55400161 |

Import and distribution of 5 cm wide 2 ton polyester conveyor belts in Kariz industrial equipment.

Sale of cargo belts

Sale of loading belts

Selling polyester belts

Sale of silk cargo belts

Flat silk carrying belt for sale

Sale of round silk carrying belt

Sale of Yalle cargo belts

Sale of Elephant cargo belt

Sale of Super SUHBO cargo belt

Selling Carl Stahl cargo belts

Sale of strength carrying belts

Selling Korean cargo belts

Selling German cargo belts

Selling Chinese cargo belts

Along with steel rope tow wire, chain, crane, silk cargo belt is one of the most important equipment for lifting and moving goods.

These types of belts, which are produced by interweaving polyester threads, can be supplied in different widths and tonnages according to the needs and uses, and made in Germany, Korea, Turkey, China and Iran.

The most important features of this type of belts, in addition to high load bearing capacity, are anti-wear, flexibility, and the important feature of not damaging the cargo and goods in question.

5 cm double silk carrying strap 2 tons 1 meter Elephant Korea

5 cm double silk cargo belt 2 tons 2 meters Elephant Korea

5 cm double silk cargo belt 2 tons 3 meters Elephant Korea

5 cm double silk cargo belt 2 tons 4 meters Elephant Korea

Double 5

| |

| kariz-industrial-equipment | 021-55400161 |

| kariz-industrial-equipment |

| Iran |

| 021-55400161 |

Import and distribution of 5 cm wide 2 ton polyester conveyor belts in Kariz industrial equipment.

Sale of cargo belts

Sale of loading belts

Selling polyester belts

Sale of silk cargo belts

Flat silk carrying belt for sale

Sale of round silk carrying belt

Sale of Yalle cargo belts

Sale of Elephant cargo belt

Sale of Super SUHBO cargo belt

Selling Carl Stahl cargo belts

Sale of strength carrying belts

Selling Korean cargo belts

Selling German cargo belts

Selling Chinese cargo belts

Along with steel rope tow wire, chain, crane, silk cargo belt is one of the most important equipment for lifting and moving goods.

These types of belts, which are produced by interweaving polyester threads, can be supplied in different widths and tonnages according to the needs and uses, and made in Germany, Korea, Turkey, China and Iran.

The most important features of this type of belts, in addition to high load bearing capacity, are anti-wear, flexibility, and the important feature of not damaging the cargo and goods in question.

5 cm double silk carrying strap 2 tons 1 meter Elephant Korea

5 cm double silk cargo belt 2 tons 2 meters Elephant Korea

5 cm double silk cargo belt 2 tons 3 meters Elephant Korea

5 cm double silk cargo belt 2 tons 4 meters Elephant Korea

Double 5

| |

| kariz-industrial-equipment | 021-55400161 |

| kariz-industrial-equipment |

| Iran |

| 021-55400161 |

Import and distribution of 5 cm wide 2 ton polyester conveyor belts in Kariz industrial equipment.

Sale of cargo belts

Sale of loading belts

Selling polyester belts

Sale of silk cargo belts

Flat silk carrying belt for sale

Sale of round silk carrying belt

Sale of Yalle cargo belts

Sale of Elephant cargo belt

Sale of Super SUHBO cargo belt

Selling Carl Stahl cargo belts

Sale of strength carrying belts

Selling Korean cargo belts

Selling German cargo belts

Selling Chinese cargo belts

Along with steel rope tow wire, chain, crane, silk cargo belt is one of the most important equipment for lifting and moving goods.

These types of belts, which are produced by interweaving polyester threads, can be supplied in different widths and tonnages according to the needs and uses, and made in Germany, Korea, Turkey, China and Iran.

The most important features of this type of belts, in addition to high load bearing capacity, are anti-wear, flexibility, and the important feature of not damaging the cargo and goods in question.

5 cm double silk carrying strap 2 tons 1 meter Elephant Korea

5 cm double silk cargo belt 2 tons 2 meters Elephant Korea

5 cm double silk cargo belt 2 tons 3 meters Elephant Korea

5 cm double silk cargo belt 2 tons 4 meters Elephant Korea

Double 5

| |

| kariz-industrial-equipment | 021-55400161 |

| kariz-industrial-equipment |

| Iran |

| 021-55400161 |

Import and distribution of 5 cm wide 2 ton polyester conveyor belts in Kariz industrial equipment.

Sale of cargo belts

Sale of loading belts

Selling polyester belts

Sale of silk cargo belts

Flat silk carrying belt for sale

Sale of round silk carrying belt

Sale of Yalle cargo belts

Sale of Elephant cargo belt

Sale of Super SUHBO cargo belt

Selling Carl Stahl cargo belts

Sale of strength carrying belts

Selling Korean cargo belts

Selling German cargo belts

Selling Chinese cargo belts

Along with steel rope tow wire, chain, crane, silk cargo belt is one of the most important equipment for lifting and moving goods.

These types of belts, which are produced by interweaving polyester threads, can be supplied in different widths and tonnages according to the needs and uses, and made in Germany, Korea, Turkey, China and Iran.

The most important features of this type of belts, in addition to high load bearing capacity, are anti-wear, flexibility, and the important feature of not damaging the cargo and goods in question.

5 cm double silk carrying strap 2 tons 1 meter Elephant Korea

5 cm double silk cargo belt 2 tons 2 meters Elephant Korea

5 cm double silk cargo belt 2 tons 3 meters Elephant Korea

5 cm double silk cargo belt 2 tons 4 meters Elephant Korea

Double 5

| |

| kariz-industrial-equipment | 021-55400161 |

| kariz-industrial-equipment |

| Iran |

| 021-55400161 |

Import and distribution of 5 cm wide 2 ton polyester conveyor belts in Kariz industrial equipment.

Sale of cargo belts

Sale of loading belts

Selling polyester belts

Sale of silk cargo belts

Flat silk carrying belt for sale

Sale of round silk carrying belt

Sale of Yalle cargo belts

Sale of Elephant cargo belt

Sale of Super SUHBO cargo belt

Selling Carl Stahl cargo belts

Sale of strength carrying belts

Selling Korean cargo belts

Selling German cargo belts

Selling Chinese cargo belts

Along with steel rope tow wire, chain, crane, silk cargo belt is one of the most important equipment for lifting and moving goods.

These types of belts, which are produced by interweaving polyester threads, can be supplied in different widths and tonnages according to the needs and uses, and made in Germany, Korea, Turkey, China and Iran.

The most important features of this type of belts, in addition to high load bearing capacity, are anti-wear, flexibility, and the important feature of not damaging the cargo and goods in question.

5 cm double silk carrying strap 2 tons 1 meter Elephant Korea

5 cm double silk cargo belt 2 tons 2 meters Elephant Korea

5 cm double silk cargo belt 2 tons 3 meters Elephant Korea

5 cm double silk cargo belt 2 tons 4 meters Elephant Korea

Double 5

| |

| kariz-industrial-equipment | 021-55400161 |

| kariz-industrial-equipment |

| Iran |

| 021-55400161 |

Import and distribution of 5 cm wide 2 ton polyester conveyor belts in Kariz industrial equipment.

Sale of cargo belts

Sale of loading belts

Selling polyester belts

Sale of silk cargo belts

Flat silk carrying belt for sale

Sale of round silk carrying belt

Sale of Yalle cargo belts

Sale of Elephant cargo belt

Sale of Super SUHBO cargo belt

Selling Carl Stahl cargo belts

Sale of strength carrying belts

Selling Korean cargo belts

Selling German cargo belts

Selling Chinese cargo belts

Along with steel rope tow wire, chain, crane, silk cargo belt is one of the most important equipment for lifting and moving goods.

These types of belts, which are produced by interweaving polyester threads, can be supplied in different widths and tonnages according to the needs and uses, and made in Germany, Korea, Turkey, China and Iran.

The most important features of this type of belts, in addition to high load bearing capacity, are anti-wear, flexibility, and the important feature of not damaging the cargo and goods in question.

5 cm double silk carrying strap 2 tons 1 meter Elephant Korea

5 cm double silk cargo belt 2 tons 2 meters Elephant Korea

5 cm double silk cargo belt 2 tons 3 meters Elephant Korea

5 cm double silk cargo belt 2 tons 4 meters Elephant Korea

Double 5

| |

| kariz-industrial-equipment | 021-55400161 |

| kariz-industrial-equipment |

| Iran |

| 021-55400161 |

Import and distribution of 5 cm wide 2 ton polyester conveyor belts in Kariz industrial equipment.

Sale of cargo belts

Sale of loading belts

Selling polyester belts

Sale of silk cargo belts

Flat silk carrying belt for sale

Sale of round silk carrying belt

Sale of Yalle cargo belts

Sale of Elephant cargo belt

Sale of Super SUHBO cargo belt

Selling Carl Stahl cargo belts

Sale of strength carrying belts

Selling Korean cargo belts

Selling German cargo belts

Selling Chinese cargo belts

Along with steel rope tow wire, chain, crane, silk cargo belt is one of the most important equipment for lifting and moving goods.

These types of belts, which are produced by interweaving polyester threads, can be supplied in different widths and tonnages according to the needs and uses, and made in Germany, Korea, Turkey, China and Iran.

The most important features of this type of belts, in addition to high load bearing capacity, are anti-wear, flexibility, and the important feature of not damaging the cargo and goods in question.

5 cm double silk carrying strap 2 tons 1 meter Elephant Korea

5 cm double silk cargo belt 2 tons 2 meters Elephant Korea

5 cm double silk cargo belt 2 tons 3 meters Elephant Korea

5 cm double silk cargo belt 2 tons 4 meters Elephant Korea

Double 5

| |

| kariz-industrial-equipment | 021-55400161 |

| kariz-industrial-equipment |

| Iran |

| 021-55400161 |

Import and distribution of 5 cm wide 2 ton polyester conveyor belts in Kariz industrial equipment.

Sale of cargo belts

Sale of loading belts

Selling polyester belts

Sale of silk cargo belts

Flat silk carrying belt for sale

Sale of round silk carrying belt

Sale of Yalle cargo belts

Sale of Elephant cargo belt

Sale of Super SUHBO cargo belt

Selling Carl Stahl cargo belts

Sale of strength carrying belts

Selling Korean cargo belts

Selling German cargo belts

Selling Chinese cargo belts

Along with steel rope tow wire, chain, crane, silk cargo belt is one of the most important equipment for lifting and moving goods.

These types of belts, which are produced by interweaving polyester threads, can be supplied in different widths and tonnages according to the needs and uses, and made in Germany, Korea, Turkey, China and Iran.

The most important features of this type of belts, in addition to high load bearing capacity, are anti-wear, flexibility, and the important feature of not damaging the cargo and goods in question.

5 cm double silk carrying strap 2 tons 1 meter Elephant Korea

5 cm double silk cargo belt 2 tons 2 meters Elephant Korea

5 cm double silk cargo belt 2 tons 3 meters Elephant Korea

5 cm double silk cargo belt 2 tons 4 meters Elephant Korea

Double 5

| |

| kariz-industrial-equipment | 021-55400161 |

| kariz-industrial-equipment |

| Iran |

| 021-55400161 |

Import and distribution of 5 cm wide 2 ton polyester conveyor belts in Kariz industrial equipment.

Sale of cargo belts

Sale of loading belts

Selling polyester belts

Sale of silk cargo belts

Flat silk carrying belt for sale

Sale of round silk carrying belt

Sale of Yalle cargo belts

Sale of Elephant cargo belt

Sale of Super SUHBO cargo belt

Selling Carl Stahl cargo belts

Sale of strength carrying belts

Selling Korean cargo belts

Selling German cargo belts

Selling Chinese cargo belts

Along with steel rope tow wire, chain, crane, silk cargo belt is one of the most important equipment for lifting and moving goods.

These types of belts, which are produced by interweaving polyester threads, can be supplied in different widths and tonnages according to the needs and uses, and made in Germany, Korea, Turkey, China and Iran.

The most important features of this type of belts, in addition to high load bearing capacity, are anti-wear, flexibility, and the important feature of not damaging the cargo and goods in question.

5 cm double silk carrying strap 2 tons 1 meter Elephant Korea

5 cm double silk cargo belt 2 tons 2 meters Elephant Korea

5 cm double silk cargo belt 2 tons 3 meters Elephant Korea

5 cm double silk cargo belt 2 tons 4 meters Elephant Korea

Double 5

| |

| kariz-industrial-equipment | 021-55400161 |

| kariz-industrial-equipment |

| Iran |

| 021-55400161 |

Import and distribution of 5 cm wide 2 ton polyester conveyor belts in Kariz industrial equipment.

Sale of cargo belts

Sale of loading belts

Selling polyester belts

Sale of silk cargo belts

Flat silk carrying belt for sale

Sale of round silk carrying belt

Sale of Yalle cargo belts

Sale of Elephant cargo belt

Sale of Super SUHBO cargo belt

Selling Carl Stahl cargo belts

Sale of strength carrying belts

Selling Korean cargo belts

Selling German cargo belts

Selling Chinese cargo belts

Along with steel rope tow wire, chain, crane, silk cargo belt is one of the most important equipment for lifting and moving goods.

These types of belts, which are produced by interweaving polyester threads, can be supplied in different widths and tonnages according to the needs and uses, and made in Germany, Korea, Turkey, China and Iran.

The most important features of this type of belts, in addition to high load bearing capacity, are anti-wear, flexibility, and the important feature of not damaging the cargo and goods in question.

5 cm double silk carrying strap 2 tons 1 meter Elephant Korea

5 cm double silk cargo belt 2 tons 2 meters Elephant Korea

5 cm double silk cargo belt 2 tons 3 meters Elephant Korea

5 cm double silk cargo belt 2 tons 4 meters Elephant Korea

Double 5

| |

| kariz-industrial-equipment | 021-55400161 |

| kariz-industrial-equipment |

| Iran |

| 021-55400161 |

Import and distribution of 5 cm wide 2 ton polyester conveyor belts in Kariz industrial equipment.

Sale of cargo belts

Sale of loading belts

Selling polyester belts

Sale of silk cargo belts

Flat silk carrying belt for sale

Sale of round silk carrying belt

Sale of Yalle cargo belts

Sale of Elephant cargo belt

Sale of Super SUHBO cargo belt

Selling Carl Stahl cargo belts

Sale of strength carrying belts

Selling Korean cargo belts

Selling German cargo belts

Selling Chinese cargo belts

Along with steel rope tow wire, chain, crane, silk cargo belt is one of the most important equipment for lifting and moving goods.

These types of belts, which are produced by interweaving polyester threads, can be supplied in different widths and tonnages according to the needs and uses, and made in Germany, Korea, Turkey, China and Iran.

The most important features of this type of belts, in addition to high load bearing capacity, are anti-wear, flexibility, and the important feature of not damaging the cargo and goods in question.

5 cm double silk carrying strap 2 tons 1 meter Elephant Korea

5 cm double silk cargo belt 2 tons 2 meters Elephant Korea

5 cm double silk cargo belt 2 tons 3 meters Elephant Korea

5 cm double silk cargo belt 2 tons 4 meters Elephant Korea

Double 5

| |

| kariz-industrial-equipment | 021-55400161 |

| kariz-industrial-equipment |

| Iran |

| 021-55400161 |

Import and distribution of 5 cm wide 2 ton polyester conveyor belts in Kariz industrial equipment.

Sale of cargo belts

Sale of loading belts

Selling polyester belts

Sale of silk cargo belts

Flat silk carrying belt for sale

Sale of round silk carrying belt

Sale of Yalle cargo belts

Sale of Elephant cargo belt

Sale of Super SUHBO cargo belt

Selling Carl Stahl cargo belts

Sale of strength carrying belts

Selling Korean cargo belts

Selling German cargo belts

Selling Chinese cargo belts

Along with steel rope tow wire, chain, crane, silk cargo belt is one of the most important equipment for lifting and moving goods.

These types of belts, which are produced by interweaving polyester threads, can be supplied in different widths and tonnages according to the needs and uses, and made in Germany, Korea, Turkey, China and Iran.

The most important features of this type of belts, in addition to high load bearing capacity, are anti-wear, flexibility, and the important feature of not damaging the cargo and goods in question.

5 cm double silk carrying strap 2 tons 1 meter Elephant Korea

5 cm double silk cargo belt 2 tons 2 meters Elephant Korea

5 cm double silk cargo belt 2 tons 3 meters Elephant Korea

5 cm double silk cargo belt 2 tons 4 meters Elephant Korea

Double 5

| |

| kariz-industrial-equipment | 021-55400161 |

| kariz-industrial-equipment |

| Iran |

| 021-55400161 |

Import and distribution of 5 cm wide 2 ton polyester conveyor belts in Kariz industrial equipment.

Sale of cargo belts

Sale of loading belts

Selling polyester belts

Sale of silk cargo belts

Flat silk carrying belt for sale

Sale of round silk carrying belt

Sale of Yalle cargo belts

Sale of Elephant cargo belt

Sale of Super SUHBO cargo belt

Selling Carl Stahl cargo belts

Sale of strength carrying belts

Selling Korean cargo belts

Selling German cargo belts

Selling Chinese cargo belts

Along with steel rope tow wire, chain, crane, silk cargo belt is one of the most important equipment for lifting and moving goods.

These types of belts, which are produced by interweaving polyester threads, can be supplied in different widths and tonnages according to the needs and uses, and made in Germany, Korea, Turkey, China and Iran.

The most important features of this type of belts, in addition to high load bearing capacity, are anti-wear, flexibility, and the important feature of not damaging the cargo and goods in question.

5 cm double silk carrying strap 2 tons 1 meter Elephant Korea

5 cm double silk cargo belt 2 tons 2 meters Elephant Korea

5 cm double silk cargo belt 2 tons 3 meters Elephant Korea

5 cm double silk cargo belt 2 tons 4 meters Elephant Korea

Double 5

| |

| kariz-industrial-equipment | 021-55400161 |

| kariz-industrial-equipment |

| Iran |

| 021-55400161 |

Import and distribution of 5 cm wide 2 ton polyester conveyor belts in Kariz industrial equipment.

Sale of cargo belts

Sale of loading belts

Selling polyester belts

Sale of silk cargo belts

Flat silk carrying belt for sale

Sale of round silk carrying belt

Sale of Yalle cargo belts

Sale of Elephant cargo belt

Sale of Super SUHBO cargo belt

Selling Carl Stahl cargo belts

Sale of strength carrying belts

Selling Korean cargo belts

Selling German cargo belts

Selling Chinese cargo belts

Along with steel rope tow wire, chain, crane, silk cargo belt is one of the most important equipment for lifting and moving goods.

These types of belts, which are produced by interweaving polyester threads, can be supplied in different widths and tonnages according to the needs and uses, and made in Germany, Korea, Turkey, China and Iran.

The most important features of this type of belts, in addition to high load bearing capacity, are anti-wear, flexibility, and the important feature of not damaging the cargo and goods in question.

5 cm double silk carrying strap 2 tons 1 meter Elephant Korea

5 cm double silk cargo belt 2 tons 2 meters Elephant Korea

5 cm double silk cargo belt 2 tons 3 meters Elephant Korea

5 cm double silk cargo belt 2 tons 4 meters Elephant Korea

Double 5

| |

| kariz-industrial-equipment | 021-55400161 |

| power-belt |

| Iran |

| 021-22087856 |

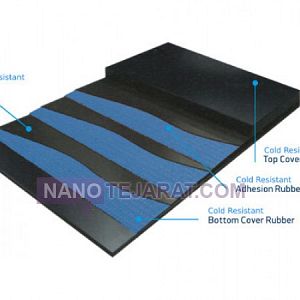

The V-shaped butterfly belt is one of the most widely used types of belts for power transmission between pulleys in various industrial machines and automotive systems. Designed with a trapezoidal cross-section, it fits precisely into the V-shaped grooves of pulleys, increasing friction and preventing slippage during power transfer. The materials used in its construction typically include rubber layers reinforced with tensile-resistant fibers or cords, providing excellent durability against stretching and heat. This multi-layer structure allows the belt to resist deformation, cracking, and wear, ensuring stable performance under high-stress conditions.

Technically, the V-shaped belt is manufactured in various sizes and profiles such as A, B, C, or SPZ, SPA, and SPB to suit different pulleys and power transmission systems. These belts operate efficiently within a temperature range of -30 to +80 degrees Celsius and offer resistance to oil, dust, and harsh environmental conditions. One of the key advantages of the V-shaped butterfly belt is its ability to deliver smooth power transmission with minimal noise and vibration, contributing to the extended lifespan of connected mechanical components. Easy installation, high serviceability, and low maintenance costs make this type of bel

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

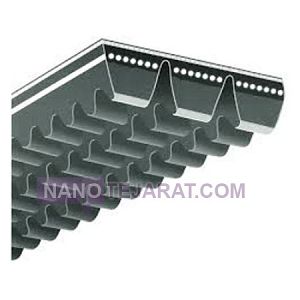

Polycord belt with polyester reinforcement is a multi-layer power transmission belt designed for high-precision applications requiring stable tensile performance. The outer layer is made of thermoplastic polyurethane with a hardness between 90 and 95 Shore A, offering excellent resistance to abrasion, tearing, and chemical exposure. A reinforced polyester core is embedded within the belt to absorb tensile loads and minimize long-term elongation. Standard diameters typically range from 5 to 15 millimeters, with tensile strength measured between 70 and 100 megapascals. These belts operate reliably within a temperature range of -15 to +80 degrees Celsius and support accurate thermal welding for seamless joining.

The polyester core in the polycord belt improves performance in systems with frequent starts and stops by preventing undesired longitudinal stretch. Required initial tension during installation is typically lower than non-reinforced belts, defined between 3% and 5%. This reduces bearing loads and extends the service life of mechanical components. Polycord belts with polyester reinforcement are ideal for packaging machinery, robotics, precision automation systems, and conveyors with sensitive positioning requirements. The maximum permissible linear speed is up to 30 meters

.jpg?width=160&height=160&cropratio=160:160&image=/admin/uploads/تسمه-پلی-کرد-با-مغزی-پلی-استر-Polycord-belt-with-polyester-core-پاور-بلت-94-u3092-bd5270-New Project (23).jpg&url=/admin/uploads/تسمه-پلی-کرد-با-مغزی-پلی-استر-Polycord-belt-with-polyester-core-پاور-بلت-94-u3092-bd5270-New Project (23).jpg)

.jpg?width=300&height=300&cropratio=300:300&image=/admin/uploads/تسمه-پلی-کرد-با-مغزی-پلی-استر-Polycord-belt-with-polyester-core-پاور-بلت-94-u3092-bd5270-New Project (23).jpg&url=/admin/uploads/تسمه-پلی-کرد-با-مغزی-پلی-استر-Polycord-belt-with-polyester-core-پاور-بلت-94-u3092-bd5270-New Project (23).jpg) | |

| power-belt | 021-22087856 |

| sanatariya |

| Iran |

| 02133116613-33961181-3 |

The timing belt is a critical component in power transmission systems responsible for precise synchronization between the crankshaft and camshaft. These belts are typically made from neoprene rubber reinforced with fiberglass or Kevlar fibers. The tensile strength of the belt ranges from 1500 to 3000 Newtons, preventing elongation under load conditions. The belt width varies between 10 and 40 millimeters, with a thickness generally between 4 and 8 millimeters. The belt teeth are designed with a pitch of 8 or 9.525 millimeters to ensure precise engagement with pulleys. ISO 13050 and DIN 7721 standards are commonly applied to control the quality of timing belt manufacturing.

The tooth profile of timing belts can be trapezoidal, curvilinear, or RPP, each optimized for specific operating conditions. Belts are produced in open or endless loop types, commonly ranging from 500 to 1600 millimeters in length. The operating temperature range is defined from -30 to +120 degrees Celsius. In industrial and automotive applications, the belt must operate slip-free with minimal deviation. The expected service life under standard conditions is between 60,000 and 100,000 kilometers or approximately 5,000 hours of operation. Manufacturing quality, uniform thickness, and precise tooth molding s

| |

| sanatariya | 02133116613-33961181-3 |

| power-belt |

| Iran |

| 021-22087856 |

The plastic food-grade conveyor belt is one of the most essential components in food industry transport systems, designed with specific technical features to enhance production line efficiency. These belts are typically made from polyethylene PE, polypropylene PP, or polyoxymethylene POM, offering high resistance to moisture, grease, mild chemicals, and temperature fluctuations. The surface of these belts is either smooth or textured to prevent food slippage and is designed for easy cleaning with disinfectants. Their temperature tolerance generally ranges from -40 to +90 degrees Celsius, making them suitable for both cold storage and baking line applications.

From a mechanical perspective, plastic food conveyor belts feature a modular or continuous design, allowing for easy installation, maintenance, and part replacement. These belts comply with international hygiene standards such as FDA and EU regulations, and are free from toxic materials that could pose risks during direct contact with food. With various widths and thicknesses available, and adjustable movement speeds, they are ideal for a wide range of applications including packaging, washing, sorting, and transporting food products. Additionally, their high resistance to wear and tear ensures a long service life, reduci

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The flat butterfly belt, known as the Flat butterfly belt, is a type of power transmission belt featuring a wide and smooth surface, commonly used for power transfer in various industrial and mechanical systems. These belts are typically made from durable materials such as natural or synthetic rubber combined with reinforced layers of polyester or nylon cords, enhancing tensile strength and flexibility. The flat surface design allows for greater contact with the pulley, enabling uniform and slip-free power transmission at different speeds. Additionally, due to their simple structure and lightweight nature, these belts are considered an economical and efficient choice for industrial applications.

Technically, the flat butterfly belt can operate across a wide temperature range and offers good resistance to moisture, oil, and abrasion. They are manufactured in various sizes and thicknesses to meet the diverse needs of different industries. Thanks to their smooth and uniform structure, these belts provide quiet, vibration-free operation, which contributes to the extended lifespan of the equipment connected to the power transmission system. Easy installation and low maintenance costs are other advantages that make the flat butterfly belt a popular choice in industries such as texti

| |

| power-belt | 021-22087856 |

| sanatariya |

| Iran |

| 02133116613-33961181-3 |

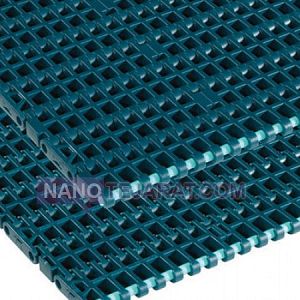

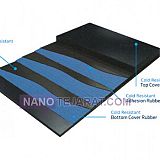

The 4-star conveyor belt is among the most durable models designed for heavy-duty industrial applications under harsh operating conditions. This belt features a multilayer structure with four plies of polyester-nylon EP 125 to EP 250 fabric, cross-reinforced with abrasion-resistant rubber. The total thickness ranges from 8 to 14 millimeters, and the maximum allowable tensile strength reaches up to 1600 Newtons per millimeter of belt width. Its dry tensile strength is measured at up to 25 MPa, while in humid conditions it remains around 18 MPa. The top surface can be either smooth or patterned such as Chevron or Rough Top to prevent load slippage on inclined surfaces.

The operating temperature range for the 4-star conveyor belt spans from -30 to +120 degrees Celsius, with special models rated up to 150 degrees. This belt offers strong resistance to mineral oils, industrial grease, and surface abrasion from sharp particles. In abrasion loss testing according to ISO 4649, volume loss remains under 120 mm³. It supports continuous industrial use at speeds up to 4.5 meters per second. Common applications include mining operations, cement plants, power stations, and steel manufacturing industries. The bottom layer is typically made from tear-resistant and flame-retardant rubber comp

| |

| sanatariya | 02133116613-33961181-3 |

| power-belt |

| Iran |

| 021-22087856 |

The metric timing belt is manufactured from neoprene rubber or polyurethane reinforced with fiberglass or steel cords to ensure precise and slip-free power transmission. The tooth pitch varies from 2 millimeters to 20 millimeters depending on the standard, while tooth height ranges between 0.8 and 5 millimeters. The tensile strength of these belts is typically in the range of 500 to 3000 newtons per centimeter, enabling use in heavy-duty industrial systems. The operating temperature range of the metric timing belt is between -30 and 100 degrees Celsius, with short-term resistance up to 120 degrees Celsius. High wear resistance, along with oil and moisture tolerance, are also key features of this product.

Other technical specifications include high accuracy in tooth alignment and long-term dimensional stability. The belt width is produced from 6 to 150 millimeters depending on application, and standard rolls are offered in lengths of 50 or 100 meters. The minimum bending radius usually ranges between 20 and 80 millimeters, allowing use with small pulleys. The surface hardness is typically between 80 and 92 Shore A, providing strong resistance against deformation. These belts are designed according to international standards ISO 5296 and DIN 7721, and are widely applied in autom

| |

| power-belt | 021-22087856 |

| yeekta-bearings |

| Iran |

| 021-33925513 |

MEGADYNE industrial timing belts are precision-engineered power transmission components manufactured according to ISO and DIN standards. These belts are typically made from abrasion-resistant polyurethane combined with steel or Kevlar tension cords. Their tensile strength ranges between 2000 and 3500 Newtons and they operate reliably in temperatures from -30 to +100 degrees Celsius. Common tooth pitches in models like RPP or T range from 5 to 14 millimeters. MEGADYNE belts are available in standard widths from 10 to 85 millimeters. High-precision molding of the teeth minimizes noise and vibration in industrial applications.

MEGADYNE’s industrial models such as MEGAflex and MEGApower are designed for high-speed, high-torque, and precision-driven systems. These belts have a service life exceeding 20,000 operating hours under standard conditions. The tooth profiles are curvilinear or parabolic to evenly distribute surface stress and reduce wear. Overall belt thickness typically ranges from 4.5 to 10 millimeters, and open-ended lengths up to 20 meters are available upon request. MEGADYNE industrial timing belts are fully compatible with standard HTD and RPP pulleys. Accurate transmission ratio, precise alignment, and low maintenance make them ideal for automation, packaging, and

| |

| yeekta-bearings | 021-33925513 |

| power-belt |

| Iran |

| 021-22087856 |

The multi-groove propeller belt, also known as the multi-rib belt, is one of the most advanced types of power transmission belts. Its design features multiple parallel grooves on its surface, allowing it to simultaneously and uniformly transfer power to several pulleys. This unique design increases the contact area between the belt and pulleys, reducing slippage and enhancing transmission efficiency. Typically made from a combination of rubber and reinforced fibers, these belts offer high flexibility along with significant resistance to tension, abrasion, and heat. The multi-groove structure enables its use in more complex systems requiring higher power and speed capacities.

Technically, the multi-groove propeller belt is manufactured in various sizes and groove counts to ensure compatibility with different pulley types and meet diverse industrial demands. These belts exhibit high resistance to environmental factors such as moisture, oil, dust, and temperature ranges from -30 to +90 degrees Celsius. Additionally, they operate smoothly and quietly, minimizing vibration and extending the service life of connected equipment. Due to their durability, easy installation, and low maintenance costs, multi-groove propeller belts are widely used in automotive, heavy machinery, agricultu

| |

| power-belt | 021-22087856 |

| pishrosanat |

| Iran |

| 09123691065 |

A timing belt is a mechanical component with internal teeth that ensures precise synchronization between the crankshaft and camshaft in internal combustion engines. The belt width varies depending on engine type, typically between 15 and 40 millimeters, with a thickness of about 4 to 8 millimeters. The tooth pitch is usually 8 or 9.525 millimeters, and the number of teeth ranges from 100 to 160. Timing belts are made from rubber reinforced with fiberglass, nylon, or Kevlar. The standard operating temperature range is from -30 to +120 degrees Celsius. The tensile strength of the belt typically ranges from 1500 to 2500 Newtons, offering high resistance to impact stress.

The tooth profile of a timing belt may be trapezoidal or curvilinear, each designed to match specific pulley types. The typical belt length ranges from 800 to 1600 millimeters, with a weight of approximately 200 to 600 grams. International standards such as ISO 9010 and DIN 7721 govern the geometric design and material resistance of timing belts. The belt must operate slip-free and be precisely aligned with pulleys to prevent valve damage. Under normal conditions, the timing belt lifespan is between 60,000 and 100,000 kilometers. In turbocharged or high-RPM engines, this interval should be shortened to minimize t

| |

| pishrosanat | 09123691065 |

| power-belt |

| Iran |

| 021-22087856 |

A bone-shaped welded flat bar is a metal section with a distinctive cross-sectional profile resembling a bone, designed to withstand tensile and bending loads in industrial structures. It is made from carbon steel with a carbon content of 0.15 to 0.30 percent and has a tensile strength of 380 to 520 megapascals. The central section width typically ranges from 20 to 100 millimeters, while the flange width varies between 30 and 150 millimeters. The thickness of the bone-shaped welded flat bar is between 3 and 10 millimeters, with dimensional tolerances of ±0.5 millimeters in width and ±0.2 millimeters in thickness. The surface finish can be hot rolled, oiled, or galvanized.

The manufacturing process of a bone-shaped welded flat bar includes cutting steel sheets, forming the special profile, and joining the edges using resistance or laser welding with precise control of temperature and pressure. The surface hardness of this product ranges from 120 to 180 Brinell, and it offers cold bending and precise punching capabilities. It is manufactured according to standards such as DIN EN 10149 or ASTM A1011, ensuring metallurgical quality and dimensional uniformity. Bone-shaped welded flat bars are widely used in the automotive industry, machinery manufacturing, and lightweight steel s

| |

| power-belt | 021-22087856 |

| Roll-pars-belt-bearing |

| Iran |

| 09126482568 |

The price of industrial belts is influenced by various factors such as the raw material type, thickness, width, and length of the belt. Industrial belts are typically made from polyurethane, rubber, or neoprene, each having different price points. Belt thickness ranges from 2 to 10 millimeters, with each additional millimeter increasing the price by approximately 5 to 10 percent. Additionally, the belt width directly affects the price wider belts generally cost more. The belt length is usually calculated per square meter, and the final price is determined based on the customers order. In the market, the price of welding wire is also considered as a comparative benchmark when estimating total project costs.

International standards such as DIN 2215 and ISO 4184 significantly impact the quality and price of industrial belts. Standard belts feature tensile strength up to 2000 Newtons per millimeter and can withstand temperatures between -20 and +80 degrees Celsius. Manufacturing quality, abrasion resistance, and chemical resistance also influence the belt’s price. Abrasion-resistant and oil-resistant belts are priced higher than regular types. Ultimately, the price of welding wire and industrial belts should be evaluated based on quality and project requirements to optimize cost

| |

| Roll-pars-belt-bearing | 09126482568 |

| power-belt |

| Iran |

| 021-22087856 |

The Megadyne RPP3 timing belt is manufactured from polychloroprene rubber reinforced with glass fiber cords and coated with nylon fabric, providing excellent tensile strength and abrasion resistance. This belt has a 3-millimeter pitch, and its “Robust Profile” RPP tooth design increases surface contact while minimizing slippage during power transmission. Its tensile strength is measured between 70 and 100 newtons per millimeter of belt width, with a friction coefficient of approximately 0.3. The standard operating temperature range of the Megadyne RPP3 timing belt is from -20 to +100 degrees Celsius, while heat-resistant versions can operate effectively up to 120 degrees.

A key feature of the Megadyne RPP3 timing belt is its high accuracy in synchronization and power transmission with low vibration and reduced noise. It delivers stable performance at speeds up to 9,000 revolutions per minute, with available widths ranging from 9 to 25 millimeters. Standard lengths are produced between 180 and 1500 millimeters, and the curved tooth profile helps reduce stress concentration while extending service life. These specifications make the Megadyne RPP3 timing belt an ideal solution for precision industrial equipment and high-efficiency machinery.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

A multi-rib power transmission belt is designed for high-efficiency mechanical power transfer and can transmit several kilowatts of power simultaneously. The width and depth of the ribs are manufactured with ±0.1 mm accuracy to minimize slippage and maximize surface contact. The materials are typically a combination of heat-resistant polymers and steel-reinforced fibers, providing tensile strength up to 5000 N. The rib angle and spacing are designed according to DIN 7867 or ISO 9981 standards to reduce vibration while extending belt life. Wear resistance and an operating temperature range of -30 to 120°C ensure stable performance under various industrial conditions.

In engineering design, the minimum bending radius and tensile safety factor are critical for belt longevity and preventing premature failure. Tensile and fatigue tests on CNC dynamometers ensure elongation remains below 0.5%. Chemical resistance against oil, grease, and water vapor enhances long-term reliability. The friction coefficient between the rib and pulley is precisely controlled to 0.02, achieving mechanical efficiency above 95%. Using this belt in industrial machinery and heavy-duty vehicles reduces maintenance costs and prevents unexpected power transmission downtime.

| |

| power-belt | 021-22087856 |

| ebtekarsanat |

| Iran |

| 021-33990391 |

The L timing belt is a common model used in power transmission systems requiring moderate precision, designed for industrial and automotive applications. These belts are typically made of neoprene rubber reinforced with fiberglass fibers, providing tensile strength between 1200 and 2500 Newtons. The tooth pitch of the L timing belt is 9.525 millimeters, and the teeth have a trapezoidal angle designed for smooth operation with standard pulleys of this series. The belt width varies from 6 to 30 millimeters, with an overall thickness of about 5 millimeters. This belt is suitable for transmitting power at moderate speeds within a temperature range of -20 to +90 degrees Celsius.

In the design of the L timing belt, precision tooth molding plays a key role in preventing slippage and increasing belt lifespan. The expected service life of these belts ranges from 3000 to 8000 hours under standard operating conditions. Wear and oil resistance are enhanced using special coatings. The belt’s flexibility allows its use in both open and closed circuits with a minimum bending radius of 30 millimeters. These engineering specifications make the L timing belt an ideal choice for mechanical systems requiring moderate synchronization and low cost.

.jpg?width=160&height=160&cropratio=160:160&image=/admin/uploads/تسمه-تایمینگ-L---ابتکار-صنعت-51-u2231-958211-IMG_20190212_111658 (1).jpg&url=/admin/uploads/تسمه-تایمینگ-L---ابتکار-صنعت-51-u2231-958211-IMG_20190212_111658 (1).jpg)

.jpg?width=300&height=300&cropratio=300:300&image=/admin/uploads/تسمه-تایمینگ-L---ابتکار-صنعت-51-u2231-958211-IMG_20190212_111658 (1).jpg&url=/admin/uploads/تسمه-تایمینگ-L---ابتکار-صنعت-51-u2231-958211-IMG_20190212_111658 (1).jpg) | |

| ebtekarsanat | 021-33990391 |

| kariz-industrial-equipment |

| Iran |

| 021-55400161 |

Import and distribution of all kinds of round and flat silk cargo belts in Kariz industrial equipment.

Sale of silk cargo belts

Sale of round silk carrying straps

Selling tonnage carrying belts

Sale of round silk belt

Sale of round polyester belts

Sale of load carrying belts Plus Ester

What is a round cargo belt?

Round cargo carrying belts are made of first grade polyester material, and silk fibers are used in the core of the belt. Thanks to its high resistance, high flexibility and proper elongation when subjected to tensile force, polyester is a very suitable polymer material for making load carrying belts. In this type of belts, unlike flat belts inside the brain, the belt itself uses silk fibers to significantly increase the final strength. These types of belts do not have two eye ends like flat belts, and due to the circular sewing, they do not have free ends.

Round belts, like flat belts, are toned based on color. So that?

Belts in purple colors 1 tone vertical

Green 2 tones vertical

Yellow 3 tones vertical

Gray 4 tones vertical

Red 5 tones vertical

Brown 6 tones vertical

Blue 8 tones vertical

Orange is 10 vertical tones.

These types of belts are produced in higher tonnages, sometimes up to 400 vertical tons.

| |

| kariz-industrial-equipment | 021-55400161 |

| pishrosanat |

| Iran |

| 09123691065 |

A power transmission belt is typically made from elastomeric compounds such as neoprene, polyurethane, or EPDM, reinforced with fiberglass or Kevlar fibers. These belts can withstand operating temperatures ranging from -30 to +120 degrees Celsius. The power transmission efficiency of standard belts varies between 90% and 98%. Maximum belt speed in industrial applications can reach up to 60 meters per second. Initial belt tension in V-belts is typically set between 3% and 10% of belt length to prevent slippage. The torque transmission ratio can be designed between 1:1 and 1:6, depending on the belt type and application.

The average service life of a power transmission belt ranges from 10,000 to 20,000 hours, which can be extended with proper maintenance. The noise level generated by belt systems is generally below 70 decibels, significantly lower than that of chain drives. Belt width typically ranges from 10 to 100 millimeters, while thickness varies between 5 and 15 millimeters, depending on the model. Standard belts can handle up to 50 kilowatts of transmitted power in general-purpose setups. In belt system design, factors such as pulley groove angle, bending radius, and abrasion resistance are critical to proper belt selection.

| |

| pishrosanat | 09123691065 |

| Roll-pars-belt-bearing |

| Iran |

| 09126482568 |

Industrial belts are key components in power transmission and motion in machinery, made from polyurethane, rubber, or leather reinforced with metal. Belt widths typically range from 10 to 100 millimeters, with thicknesses between 2 and 10 millimeters. The tensile strength of the belts can reach up to 2000 Newtons per millimeter of width, and they can withstand temperatures from -20 to +80 degrees Celsius. These belts can operate at speeds up to 30 meters per second and are widely used in industries such as automotive, agriculture, and production lines. When selecting an industrial belt, precision in thickness, width, and tensile strength is crucial.

The price of welding wire and industrial belts is influenced by raw materials, manufacturing quality, and international standards. Industrial belts are produced according to DIN 2215 and ISO 4184 standards to ensure stable performance and long service life. Additionally, abrasion resistance and resistance to oil and chemicals are important features of high-quality belts. Uniform thickness and flexibility reduce wear on moving parts. For optimal belt selection, besides technical specifications, the price of welding wire should also be considered to optimize total project costs.

| |

| Roll-pars-belt-bearing | 09126482568 |

| ebtekarsanat |

| Iran |

| 021-33990391 |

Power transmission belts are typically made from high-strength elastomeric materials such as neoprene and polyurethane, reinforced with Kevlar or fiberglass fibers. This composition allows operation in temperatures ranging from -30 to +120 degrees Celsius and tensile strength between 10 to 40 megapascals. Belt thickness usually varies from 5 to 15 millimeters, with widths ranging from 10 to 100 millimeters. V-belt initial tension is typically set between 3% and 10% of the belt length to prevent slippage. These belts can transmit power up to 50 kilowatts, with power transmission efficiency between 90% and 98%, suitable for most industrial applications.

The service life of a power transmission belt ranges from 10,000 to 20,000 hours, influenced by maintenance and operating conditions. Maximum allowable belt speed can reach up to 60 meters per second, which is critical for high-speed applications. Belt surfaces are coated with wear- and oil-resistant layers to reduce abrasion. Additionally, friction coefficients and pulley groove angles play key roles in designing systems to ensure optimal power transfer without slippage. These parameters guarantee precise performance and operational safety of the belt system.

| |

| ebtekarsanat | 021-33990391 |

| sanatariya |

| Iran |

| 02133116613-33961181-3 |

A conveyor belt is an industrial transfer component manufactured in variable widths ranging from 300 to 1600 millimeters and a total thickness of 8 to 15 millimeters. These belts typically consist of EP fabric layers with tensile strength between 125 and 315 newtons per millimeter. The multilayer polyester-nylon structure enhances flexibility and increases operational life under high-stress conditions. The top cover, with a thickness of 3 to 6 millimeters, is made from abrasion-resistant rubber and offers resistance to non-corrosive chemicals. Abrasion resistance is below 120 cubic millimeters according to DIN standards, and the operating temperature ranges from minus 30 to plus 90 degrees Celsius.

The conveyor belt can carry bulk loads up to 180 kilograms per meter at speeds between 1 and 4 meters per second. Its bending radius ranges from 300 to 600 millimeters depending on thickness. The surface hardness is typically between 60 and 70 Shore A, ensuring effective performance on industrial rollers. These belts are used in packaging lines, mining, steel production, agriculture, and food industries. They are designed for stable, long-term performance even under continuous operation in humid environments.

| |

| sanatariya | 02133116613-33961181-3 |

| Roll-pars-belt-bearing |

| Iran |

| 09126482568 |

Online purchase of industrial belts is based on technical specifications such as belt width, thickness, and material. Belt widths typically range from 10 to 100 millimeters, with thicknesses between 2 and 10 millimeters. Belt materials include polyurethane, rubber, or neoprene, each offering specific mechanical properties. The operating temperature range of belts is between -20 and +80 degrees Celsius, with tensile strength up to 2000 Newtons per millimeter of width. The maximum working speed of belts can reach 30 meters per second. When buying online, paying attention to these technical details is crucial to ensure optimal performance.

The price of welding wire and industrial belts is a key factor in online purchases. High-quality belts usually have higher prices but guarantee longer lifespan and better efficiency. Standards such as DIN 2215 and ISO 4184 ensure the quality of industrial belts and can be verified online. Online shopping allows comparing prices and technical specifications easily. Additionally, shipping and packaging costs affect the final price. Choosing the right industrial belt considering the price of welding wire and project requirements helps reduce overall expenses.

| |

| Roll-pars-belt-bearing | 09126482568 |

| power-belt |

| Iran |

| 021-22087856 |

The OPTIBELT DELTA CHAIN Carbon polyurethane timing belt represents one of the most advanced generations of industrial timing belts, offering exceptional performance in power transmission and tensile strength thanks to its multi-layered structure and carbon fiber reinforcement technology. The belt is made of wear-resistant, high-temperature polyurethane and features a carbon core to ensure maximum stability against stretching, deformation, and tearing. Its precisely engineered tooth profile is compatible with standard industrial pulleys, enhancing efficiency and reducing noise in mechanical systems.

A standout feature of this belt is its extremely long service life, even under high loads and at high speeds, making it an ideal choice for industrial machinery, automation systems, packaging equipment, and other precision-driven applications. Additionally, its excellent resistance to oil, chemicals, and UV radiation allows for reliable performance in harsh industrial environments and variable working conditions. The belts maintenance-free operation, easy installation, and reduced overall upkeep costs are further advantages that make the DELTA CHAIN Carbon a highly competitive solution.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The ALPHA Optibelt polyurethane timing belt is an advanced power transmission product designed with cutting-edge technology and high-quality materials. Made from abrasion-resistant polyurethane, it offers excellent resistance to oil, moisture, and high temperatures. Internally, it is reinforced with steel cords or aramid cables that ensure outstanding tensile strength and extended service life. The belt’s teeth are precisely engineered to fully engage with matching pulleys, preventing slippage and ensuring perfect synchronization in motion control systems.

The ALPHA Optibelt polyurethane timing belt is widely used in heavy industrial applications, automated systems, CNC machines, production lines, and packaging industries. These belts offer high strength, optimal flexibility, and excellent resistance to dynamic fatigue, making them ideal for continuous and high-speed operations. Their use reduces maintenance costs and downtime while enhancing operational accuracy, consistent power transmission, and overall system efficiency. Additionally, the belt can be customized in terms of length, width, and tooth profile, making it suitable for a wide range of industrial requirements.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Poly-coated welded flat bar is a type of steel strip protected with a polymer coating, offering high resistance to corrosion and wear. It is made from carbon steel with a carbon content of 0.18 to 0.28 percent and has a tensile strength ranging from 400 to 550 megapascals. The width of the poly-coated strip typically ranges from 25 to 150 millimeters, with a thickness between 3 and 8 millimeters. Dimensional tolerances are maintained at ±0.4 millimeters in width and ±0.15 millimeters in thickness. The polymer coating, applied uniformly at a thickness of 50 to 100 microns, enhances surface mechanical properties besides providing protection.

The manufacturing process of the poly-coated welded flat bar includes resistance or laser welding of the steel sheet, followed by polymer coating application through spraying or dipping methods. The surface hardness ranges from 130 to 190 Brinell, with capabilities for cold bending, precise punching, and UV resistance. This product is produced according to international standards such as ASTM A572 and DIN EN 10142, widely used in automotive industries, agricultural equipment manufacturing, and corrosion-resistant structural applications.

.png?width=160&height=160&cropratio=160:160&image=/admin/uploads/تسمه-جوشی-پلی-کرد-Welded-belt-bridge-پاور-بلت-94-u3092-d8263e-New Project (8).png&url=/admin/uploads/تسمه-جوشی-پلی-کرد-Welded-belt-bridge-پاور-بلت-94-u3092-d8263e-New Project (8).png)

.png?width=300&height=300&cropratio=300:300&image=/admin/uploads/تسمه-جوشی-پلی-کرد-Welded-belt-bridge-پاور-بلت-94-u3092-d8263e-New Project (8).png&url=/admin/uploads/تسمه-جوشی-پلی-کرد-Welded-belt-bridge-پاور-بلت-94-u3092-d8263e-New Project (8).png) | |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

An elevator belt is a critical component in vertical transport systems such as industrial elevators and bucket lifts, responsible for transmitting driving force and moving loads across different heights. These belts are typically made from durable materials like industrial rubber or polyurethane, reinforced with steel cables, aramid fibers, or polyester cords to ensure stable performance under tension, abrasion, moisture, and temperature changes. The outer surface of the belt can be smooth or textured and is designed according to the application to prevent slippage and enhance grip.

Elevator belts are used across various industries, including agriculture, food processing, mining, high-rise buildings, and automated warehouses. Selecting the appropriate belt depends on factors such as load capacity, travel speed, lift height, environmental conditions, and the type of drive system. Using a high-quality, standard-compliant belt increases system safety and prevents unexpected downtimes or potential damage. Regular tension checks, inspection of joints, and periodic maintenance are essential for extending the service life and maximizing the efficiency of the elevator system.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The Bando DXL timing belt is manufactured from neoprene rubber reinforced with glass fiber and polyester cords, providing high tensile strength and excellent dimensional stability. The standard pitch of the belt teeth ranges from 2.5 to 10 millimeters, and their surface is coated with nylon fabric to reduce friction and wear. The tensile strength of the belt is in the range of 80 to 110 newtons per millimeter of width, with a friction coefficient measured between 0.28 and 0.32. The operating temperature range is from -25 to +90 degrees Celsius, while heat-resistant models can operate effectively up to 110 degrees.

A key feature of the Bando DXL timing belt is its high precision in power transmission within synchronization systems at medium to high speeds. This belt provides stable operation up to 10,000 revolutions per minute, with available widths ranging from 6 to 40 millimeters. The length options vary from 150 to 1800 millimeters, and the semi-circular tooth design reduces vibration and noise levels to less than 68 decibels. These characteristics make the Bando DXL timing belt an ideal choice for precision industrial equipment and high-accuracy production lines.

| |

| power-belt | 021-22087856 |

| shoping-14 |

| Iran |

| 02155433645 |

The Komatsu belt tensioner is made of high-strength steel with an anti-corrosion coating and can withstand tensile forces up to 2,500 N. The shaft diameter is 25 millimeters, and the overall body length is 180 millimeters, allowing precise installation on the engine and pulleys. The internal spring is designed with a resistance of 1,200 N, maintaining constant pressure on the belt for up to 15,000 operating hours. Double-sided bearings with initial lubrication can handle rotational speeds up to 4,000 RPM, ensuring smooth movement and reduced friction of the belt. Its ergonomic and reinforced design minimizes vibration and belt wear, extending the overall system lifespan.

The belt tensioner allows both manual and automatic belt pressure adjustment and is compatible with Komatsu diesel and gasoline engines. It weighs 1.8 kilograms, and its quick-mount design facilitates easy replacement and maintenance. The spring and tensioner arm travel up to 25 millimeters, compensating for belt stretch under varying working conditions. Stable performance in ambient temperatures from -20 to 90°C and resistance to vibration and shock maximize system efficiency and belt longevity.

| |

| shoping-14 | 02155433645 |

| power-belt |

| Iran |

| 021-22087856 |

The open circuit timing belt is a key component in power transmission and position control systems used in industrial machinery and automation equipment. Unlike endless belts, it is produced without a loop and typically supplied in rolls or custom-cut lengths. This open design allows users to cut the belt precisely to the required system length. Featuring accurately spaced teeth designed to mesh perfectly with timing pulleys, the belt is commonly made from polyurethane reinforced with Kevlar or steel cords, ensuring high tensile strength, precise motion control, and long-lasting durability.

Open circuit timing belts are widely used in linear motion systems, industrial printers, CNC machines, packaging equipment, and robotic applications. These belts offer excellent resistance to wear, oil, chemicals, and harsh environmental conditions. Their maintenance-free operation and easy installation make them a cost-effective choice. Additionally, the availability of various tooth profiles and the ability to support applications that require precise positioning make the open circuit timing belt a reliable and flexible solution for engineers and industrial designers.

| |

| power-belt | 021-22087856 |

| sanatariya |

| Iran |

| 02133116613-33961181-3 |

Power transmission belts are typically made from a combination of durable elastomers such as neoprene, polyurethane, and EPDM, reinforced with Kevlar or fiberglass fibers. These belts can withstand operating temperatures ranging from -30 to +120 degrees Celsius, with tensile strength usually between 10 and 40 megapascals. Belt thickness ranges from 5 to 15 millimeters, while width varies between 10 and 100 millimeters depending on the application. Initial tension in V-belts is typically set at 3 to 10 percent of the belt length to reduce slippage. Power transmission efficiency in these systems ranges from 90 to 98 percent, and the belts can transmit power up to 50 kilowatts.

The service life of power transmission belts generally ranges from 10,000 to 20,000 hours and can be extended with proper maintenance. Maximum allowable belt speed can reach up to 60 meters per second, which is critical for high-speed applications. Belt surfaces are coated with wear- and oil-resistant layers to reduce abrasion. Key design factors include pulley groove angle, friction coefficient, and belt bending radius, all of which ensure optimal performance and prevent slippage.

| |

| sanatariya | 02133116613-33961181-3 |

| power-belt |

| Iran |

| 021-22087856 |

The 4 STAR conveyor belt is a high-quality industrial belt designed for a wide range of applications in both light and heavy industries. Made from durable PVC or PU compounds, it features a multi-layered structure to enhance tensile strength and resistance to wear. The outer surface of the belt can be smooth, grooved, or textured, depending on the specific requirements of the application. These characteristics make the 4 STAR belt a reliable choice for transporting various materials, packages, components, and products under different environmental conditions.

Technically, the 4 STAR conveyor belt offers thermal resistance in the range of -10 to +80 degrees Celsius and is engineered to withstand exposure to oils, greases, moisture, and mild chemicals. Its high flexibility and capability to operate on curved or inclined conveyor systems add to its versatility. The belt can be manufactured in different thicknesses, colors, and widths to meet diverse industrial demands. With easy installation, low maintenance, and long service life, the 4 STAR conveyor belt finds widespread use in packaging, printing, textile, pharmaceutical, and food processing industries.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The rubber closed-loop double-sided timing belt is a precise and reliable power transmission component widely used in mechanical systems and industrial automation. Its core structure consists of durable rubber compounds typically neoprene or HNBR reinforced with materials like fiberglass or aramid fibers. The key feature of this belt is the presence of teeth on both sides, allowing it to simultaneously transmit power in two different directions. This dual-sided design significantly enhances performance in systems that require synchronized, bi-directional motion.

The tooth profile is usually trapezoidal or curvilinear, ensuring high engagement accuracy with the pulley and preventing slippage. It is also highly resistant to heat, abrasion, and industrial oils. Since the belt is closed-loop, its length is fixed and usually customized to suit the specific requirements of each system, making accurate selection essential. The double-sided rubber timing belt is an ideal choice for applications such as printing machinery, packaging equipment, and robotic systems where precise and simultaneous power transmission is required in multiple directions.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

A round welded flat bar is a steel section with a circular cross section, produced by forming steel sheet and joining the longitudinal seam using resistance or laser welding. This product is typically made from low carbon steel with a carbon content of 0.15 to 0.25 percent and has a tensile strength of 350 to 500 megapascals. The diameter of the round welded flat bar can range from 6 to 60 millimeters, with a typical diameter tolerance of ±0.3 millimeters. Standard lengths are often 6 or 12 meters, and the surface can be supplied as hot rolled or galvanized.

Quality control for round welded flat bars includes tensile tests, bending tests, precise diameter measurement, and weld inspection using non-destructive methods such as ultrasonic testing. The surface hardness is between 110 and 170 Brinell, with the ability for cold bending and precision machining. This type of bar is widely used in the construction of light steel structures, mechanical equipment, and non-pressurized fluid transfer lines. It is manufactured in accordance with standards such as ASTM A108 and DIN EN 10277, ensuring dimensional accuracy and metallurgical quality.

.png?width=160&height=160&cropratio=160:160&image=/admin/uploads/تسمه-جوشی-گرد-Round-welding-belt-پاور-بلت-94-u3092-4dabdd-New Project (10).png&url=/admin/uploads/تسمه-جوشی-گرد-Round-welding-belt-پاور-بلت-94-u3092-4dabdd-New Project (10).png)

.png?width=300&height=300&cropratio=300:300&image=/admin/uploads/تسمه-جوشی-گرد-Round-welding-belt-پاور-بلت-94-u3092-4dabdd-New Project (10).png&url=/admin/uploads/تسمه-جوشی-گرد-Round-welding-belt-پاور-بلت-94-u3092-4dabdd-New Project (10).png) | |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Megadyne PU welded timing belt T10 PAZ is manufactured from durable thermoplastic polyurethane reinforced with steel or Kevlar cords, providing high tensile strength and long-lasting durability. The belt features a 10 millimeter pitch tooth profile with the PAZ series design, ensuring uniform torque and power transmission in medium-duty industrial systems and precision production lines. Its operating temperature ranges from -20 to +80 degrees Celsius, with excellent resistance to wear, oil, and moisture. Standard belt widths typically range from 16 to 100 millimeters, and thermal welding allows the creation of customized endless loops.

Due to its precise tooth design and high dimensional accuracy, this belt is ideal for packaging machinery, automated assembly lines, and precision power transmission systems. The polyurethane compound with a low friction coefficient reduces energy consumption and improves system efficiency. The broad tooth contact surface ensures uniform force distribution and minimizes vibration at high speeds. Customization in belt length and width provides significant flexibility for specialized industrial applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

Megadyne PU welded timing belt RPP14 is manufactured from durable thermoplastic polyurethane reinforced with steel or Kevlar cords, providing high tensile strength and long service life. The belt features a tooth profile with a 14 millimeter pitch, ensuring uniform torque and power transmission in heavy-duty industrial systems and high-load production lines. Its operating temperature ranges from -20 to +100 degrees Celsius, with excellent resistance to wear, oil, and moisture. Standard belt widths typically range from 25 to 115 millimeters, and thermal welding allows production of endless loop belts.

Due to its high dimensional accuracy and precisely engineered tooth design, this belt is ideal for heavy industrial machinery, automated production lines, and precision power transmission systems. The polyurethane compound with a low friction coefficient reduces energy consumption and improves system efficiency. The broad tooth contact surface ensures uniform force distribution and reduces vibration at high speeds. Additionally, customization in belt length and width provides significant flexibility for specialized industrial applications.

| |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |

The round polycord belt is made of thermoplastic polyurethane with a circular cross-section, designed for power transmission in light to medium-duty systems. The belt diameter typically ranges from 2 to 20 millimeters, with a surface hardness between 85 and 95 Shore A. Its tensile strength lies between 40 and 60 megapascals, and the operating temperature range is from -20 to +80 degrees Celsius. These belts offer good resistance to abrasion, light oils, and mild chemicals. Due to their thermoplastic structure, they can be thermally welded, simplifying installation.

The round polycord belt is designed for high flexibility and quiet operation, making it ideal for sensitive industrial applications and confined spaces. The recommended initial tension during installation is typically 5 to 8 percent of the belt length to prevent slippage and efficiency loss. The maximum linear speed these belts can handle is up to 25 meters per second. With high fatigue resistance, they provide long service life in repetitive applications. These belts are optimized for light conveyor systems, packaging machinery, and industrial automation equipment.

.png?width=160&height=160&cropratio=160:160&image=/admin/uploads/تسمه-پلی-کرد-بن-گرد-Round-polycord-belt-پاور-بلت-94-u3092-88a4d3-New Project (14).png&url=/admin/uploads/تسمه-پلی-کرد-بن-گرد-Round-polycord-belt-پاور-بلت-94-u3092-88a4d3-New Project (14).png)

.png?width=300&height=300&cropratio=300:300&image=/admin/uploads/تسمه-پلی-کرد-بن-گرد-Round-polycord-belt-پاور-بلت-94-u3092-88a4d3-New Project (14).png&url=/admin/uploads/تسمه-پلی-کرد-بن-گرد-Round-polycord-belt-پاور-بلت-94-u3092-88a4d3-New Project (14).png) | |

| power-belt | 021-22087856 |

| power-belt |

| Iran |

| 021-22087856 |