Gboard impact resistant gypsum panel , Iran

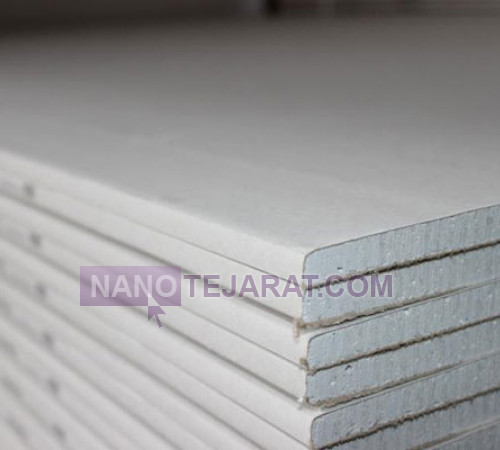

The Gboard impact resistant gypsum board features a reinforced core with special fibers that provides an approximate density of 900 to 1050 kilograms per cubic meter. The panel is produced with a thickness of 12.5 millimeters and typical dimensions of 1200 by 2400 millimeters, offering a bending resistance of about 550 to 650 newtons. Its compressed cardboard surface layer absorbs impact energy and enhances structural stability against deformation. The tapered edge design enables precise joint finishing with Knauf compounds. This product can be installed on metal framing systems using CW and UW profiles and is suitable for light to medium lateral loads.

The Gboard impact resistant gypsum panel has a thermal conductivity of approximately 0.25 watts per meter kelvin, providing efficient thermal performance for interior partitions. Sound insulation of the system combined with mineral wool can reach 45 to 52 decibels and reduces transmitted vibrations. The surface resistance of the panel against repeated impacts corresponds to a mechanical hardness exceeding 20 joules. Installation is performed using 25 to 35 millimeter self drilling screws with a maximum stud spacing of 40 centimeters. The product complies with EN 520 types D and F and is suitable for high traffic areas.You can order and buy Gboard impact resistant gypsum panel from Iran by contacting us through whatsaap and email.

WEBSITE: Gboard impact resistant gypsum panel Iran

Methods for Maintaining and Increasing the Service Life of Gboard Impact-Resistant Gypsum Board

To extend the service life of Gboard impact-resistant gypsum boards, several maintenance and operational practices must be followed. The most important factor is preventing prolonged exposure to moisture, as water infiltration can weaken the dense core and reinforcement fibers. Panels should be stored in a dry, level environment with at least 10 cm clearance from the ground to prevent bending or deformation. Using standard screws, maintaining a screw spacing of 20–25 cm, and avoiding excessive tightening are essential for preserving impact resistance. During use, heavy impacts and concentrated loads should be prevented. Proper joint filling, applying suitable paint, and periodically inspecting cracks and seams significantly contribute to long-term durability and sustained impact performance.

Fire-Resistant Gypsum Board FR K-Plus

Gboard RG standard gypsum panel

Batis RG standard gypsum panel thickness of 12.5 mm

Fire and Moisture Resistant Gypsum Board FM K-Plus

Banasan FM fire and moisture-resistant gypsum panel

flexible Gboard gypsum panel

KNAUF K plus MR moisture-resistant gypsum panel

Waliz Plus MR moisture resistant gypsum panel

Banasan FR fire-resistant gypsum panel

Gboard MR moisture resistant gypsum panel