Steel wire rope , Iran

- Price :To negotiate

- order by whatsapp

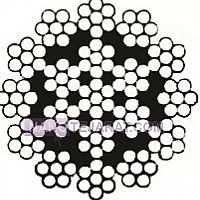

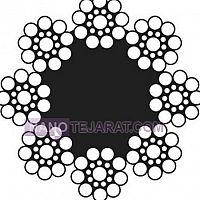

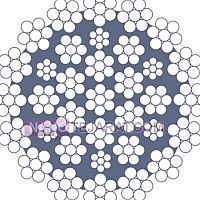

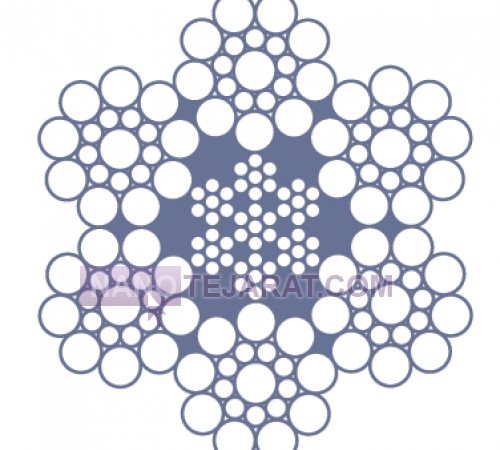

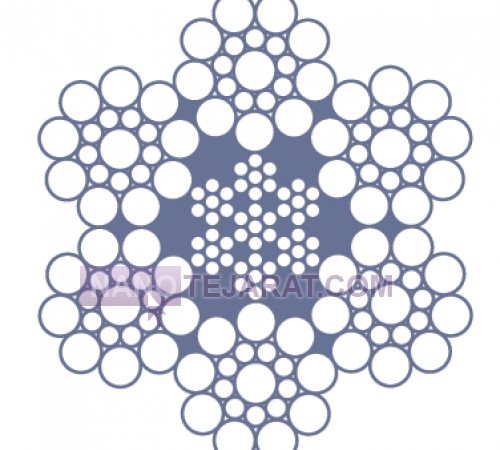

Drilling wire rope is an essential tool in the drilling industry, used for hoisting, hauling, and towing heavy equipment during drilling, mining, and oil and gas operations. These ropes are typically made from high-quality carbon steel or alloy steel, providing exceptional tensile strength and resistance to abrasion, corrosion, and pressure. Drilling wire ropes are composed of multiple strands of steel wires that are twisted and braided to offer optimal strength and flexibility. The diameter of these ropes typically ranges from 10 mm to 40 mm, and even more, depending on the type of operation and load capacity. The length of the ropes can range from several meters to over 100 meters.

Due to their ability to withstand extremely heavy loads and high pressures in drilling operations, these ropes must have high resistance. They are often coated with corrosion-resistant coatings, such as galvanization or epoxy coatings, to extend their lifespan in harsh drilling environments. Drilling wire ropes are widely used in oil and gas industries, water well drilling, mining, and other industrial operations that require hauling and towing heavy equipment. Additionally, these ropes are regularly subjected to tensile and load tests to ensure their safety and optimal performance in challenging conditions.You can order and buy Steel wire rope from Iran by contacting us through whatsaap and email.

WEBSITE: Steel wire rope Iran

Important Points in Buying and Selecting Drilling Steel Cables

When purchasing drilling steel cables, factors such as load capacity, wire diameter, abrasion resistance, and environmental conditions are crucial. The cable should withstand high weight and pressure, making the selection of the appropriate size for the drilling operation essential. Typically, cables with a diameter of 10 to 15 mm are used for standard drilling operations, while larger cables are required for deeper drilling or higher load capacities. Furthermore, resistance to corrosion and abrasion in moist or oil-contaminated environments is of significant importance. Additionally, safety standards and quality certifications are key requirements in the purchase process. Therefore, it is recommended to buy from well-known and reputable manufacturers.