Elevator rope , Iran

- Price :To negotiate

- order by whatsapp

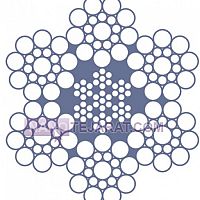

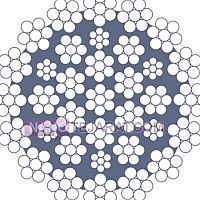

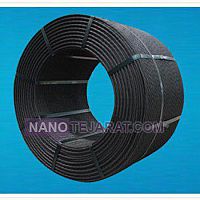

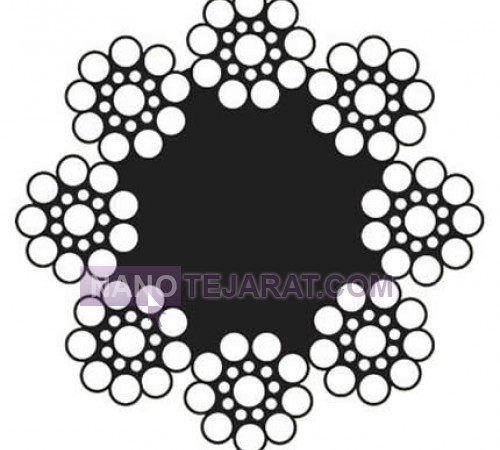

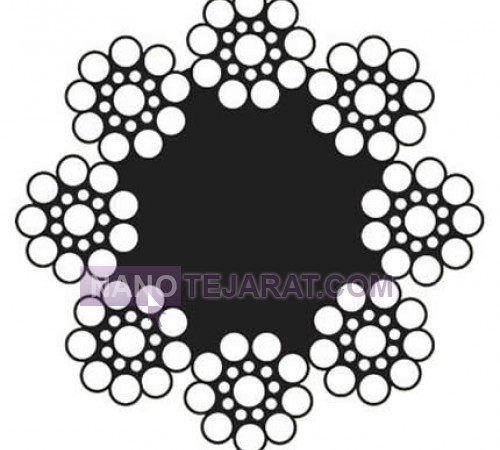

Elevator steel wire rope is one of the essential components of elevator systems, used for transferring force and enabling elevator movement. This type of wire rope is typically made from high-quality carbon steel or alloy steel, offering high tensile strength, wear resistance, and corrosion resistance. The rope is made up of several strands of steel wires that are twisted and braided, providing both flexibility and strength. The diameter of elevator wire ropes typically ranges from 6 mm to 20 mm, depending on the type of elevator and the load capacity, and they are produced in various lengths up to 150 meters or more.

These ropes are specifically designed to handle heavy loads and are ideal for use in various types of elevators, including passenger, freight, and industrial elevators. Elevator steel wire ropes are usually coated with corrosion-resistant coatings, such as galvanization or epoxy paint, to protect against moisture, corrosion, and wear. Additionally, these ropes undergo continuous tensile and load testing to ensure their quality and safety. Due to their high resistance and excellent flexibility, elevator steel wire ropes are critical tools in vertical transportation systems, ensuring safe and reliable movement of heavy loads.You can order and buy Elevator rope from Iran by contacting us through whatsaap and email.

WEBSITE: Elevator rope Iran

Safety Tips for Using Elevator Wire Ropes in Commercial Projects

Using elevator wire ropes in commercial projects requires adherence to specific safety guidelines to prevent accidents. The first important point is to carefully inspect the wire rope before each use. The rope should be free of damage such as wear, cuts, or rust. The second point is to use appropriate equipment for installing and setting up the wire rope. It is essential to use standard hooks, clamps, and pulleys with suitable capacity. Furthermore, overloading the wire rope is prohibited, and its maximum rated capacity must always be observed. During use, the wire rope should not be used to lift loads that are indirectly attached. Additionally, sudden or rapid movements of the load should be avoided, as this can damage the wire rope. Finally, training employees on proper use, safety precautions, and the importance of personal protective equipment, such as gloves and helmets, is critical.