PC STRAND , Iran

- Price :To negotiate

- order by whatsapp

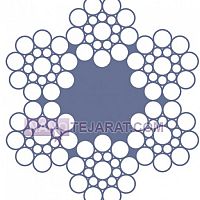

Prestressed concrete strand is a type of steel cable specifically designed for use in prestressed concrete structures. These strands are typically made from multiple steel wires that are simultaneously tensioned to apply significant tensile forces on the concrete. They are generally made from galvanized steel or corrosion-resistant alloy steel and are available in various diameters ranging from 9 to 15 mm. Prestressed strands typically have the ability to withstand forces of around 1000 to 1800 megapascals.

These strands are used in the prestressing process of concrete to reinforce concrete structures such as bridges, tunnels, roofs, and walls. Since concrete naturally has high compressive strength but is weak under tension, prestressed strands enhance the tensile strength of concrete, making it more durable. By applying tension to the concrete, these strands make the structure more resistant to cracking and expansion caused by loading forces. This feature significantly increases the lifespan of concrete structures and reduces the need for maintenance and repair.You can order and buy PC STRAND from Iran by contacting us through whatsaap and email.

WEBSITE: PC STRAND Iran

Advantages of Using Post-Tensioning Strand in the Construction of Resilient Structures

Post-tensioning strand is a modern method in building resilient structures that offers significant advantages. The first advantage is the increased tensile strength of concrete. By applying force to the steel strands during construction, concrete becomes capable of bearing higher loads. This feature is particularly important for tall structures such as bridges or multi-story buildings. The second advantage is the reduced thickness of concrete sections, leading to a decrease in the overall weight of the structure and, consequently, savings on material costs. The third advantage is resistance to cracking. The pre-stressed strands exert compressive forces on the concrete, which helps minimize the likelihood of cracks in concrete structures. Furthermore, this method improves earthquake performance and contributes to the extended service life of the structure.