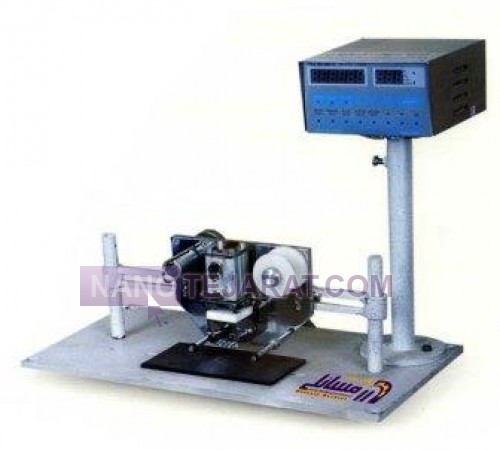

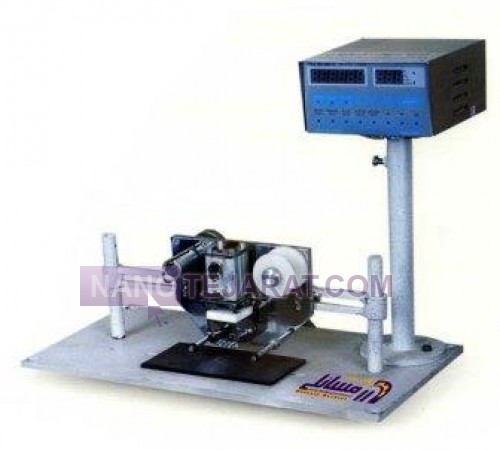

Pneumatic Impact Date Coding Machine , Iran

The pneumatic date coder uses an air cylinder with a 32 to 80 mm bore diameter. Impact force is adjustable from 50 to 500 Newtons at an operating pressure of 4 to 7 bar. Printing speed reaches up to 220 impressions per minute with positioning accuracy of ±0.5 mm. It can print on flat, curved surfaces and flexible packaging with an imprint depth of 0.1 to 1.5 mm. The date die is made of hardened steel 52-56 HRC or chrome-plated brass. The control system employs solenoid valves with a 15 ms response time and 100% duty cycle.

The structure features a 10 mm thick steel frame and a dust-resistant enclosure with IP54 rating. The print head mounting height is adjustable from 20 to 200 mm using a micrometer screw. The compressed air supply requires 50 to 150 liters per minute at 6 bar pressure. The control panel includes a digital display for setting pressure, hit count, and time delay. The sensor system is inductive or optical with a 10 mm detection range and 0-70°C temperature tolerance. The machine is manufactured in compliance with ISO 12100 machinery safety standards and CE directives.You can order and buy Pneumatic Impact Date Coding Machine from Iran by contacting us through whatsaap and email.

WEBSITE: Pneumatic Impact Date Coding Machine Iran

Advantages of Pneumatic Thermal Date Coding Machines

Pneumatic thermal date coding machines, combining thermal technology and pneumatic actuation, offer significant advantages. High operating speed due to the fast response of the pneumatic system, suitable for high-speed production lines. Excellent precision and print clarity on various surfaces like plastic, foil, and cardboard. Low energy consumption compared to all-electric systems, thanks to the use of compressed air. Greater durability and longer lifespan of mechanical parts due to reduced friction and lower heat. Precise contact pressure control by the pneumatic system, preventing damage to sensitive products. Low maintenance requirements and easy repairs due to simple mechanical structure. Cost-effectiveness compared to some advanced fully automatic systems. Ability to mount on existing conveyors and easy print position adjustment. This machine is an ideal choice for food, pharmaceutical, and chemical packaging industries.

biscuit packing machine

date packing machine

masaelipacking

Tissue packing machine

Packing machine

ice cream pillow packing machine

Packing machine

Bread packing machine

cake pillow packing machine

Pedal-Operated Heat Sealer with Date Coder