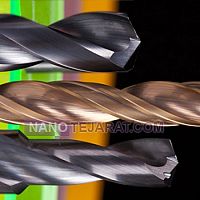

Three lathe systems , Iran

Lathe chuck is a critical and essential component in the turning process, responsible primarily for holding and securing the workpiece during rotation. Typically manufactured from hardened alloy steel, it offers high resistance to wear, mechanical stress, and the heat generated during machining operations. Lathe chucks are designed in manual or automatic types and are available in various sizes to match the diameter of the workpiece and the type of lathe machine. The jaws of the chuck are adjusted to hold the workpiece concentrically and firmly in place without slipping, which plays a vital role in achieving high machining accuracy.

Structurally, the lathe chuck consists of a robust main body, hardened jaws, and a power transmission mechanism, commonly utilizing a scroll or gear system. In automatic or hydraulic models, jaw opening and closing are controlled by air or oil pressure systems, significantly enhancing the speed and precision of workpiece changes. The precise and standardized design of the chuck reduces vibration, increases workpiece stability, and improves the final machined surface quality. When selecting a lathe chuck, it is crucial to consider parameters such as jaw diameter, clamping capacity, body material, and jaw mechanism type to ensure optimal lathe performance. Available types include two-jaw, three-jaw, and four-jaw chucks, with brands like TOOSE and BISON offering sizes of 80, 100, 125, 140, 160, 200, and 250 millimeters.You can order and buy Three lathe systems from Iran by contacting us through whatsaap and email.

WEBSITE: Three lathe systems Iran

Technical Specifications and Structure of Lathe Chuck

The lathe chuck is one of the essential components in the turning process, whose main function is to firmly and precisely hold the workpiece during rotation. This part is usually made of hardened alloy steel to provide high resistance against wear, mechanical stresses, and the heat generated during machining operations. Lathe chucks are produced in both manual and automatic types and come in various sizes compatible with the diameter of the workpiece and the type of lathe machine. The jaws of the chuck are designed to hold the workpiece concentrically and without slipping in place, which plays an important role in improving the accuracy and final surface quality of the turned workpiece. Additionally, the internal mechanism of this device, which is usually of the scroll or gear type, ensures the uniform and precise transmission of the motors power to the jaws.