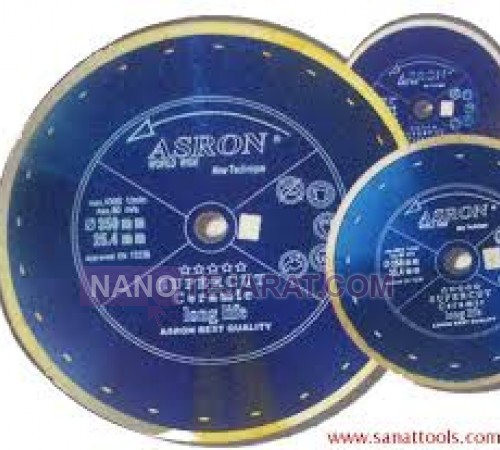

ASRON Granite and Ceramic Cutting Disc , Iran

The ASRON cutting disc is made with synthetic diamond particles of grade SDC 1200. Diamond concentration at the cutting edge reaches 4000 particles per square centimeter. Standard disc diameters range from 105 to 350 mm for industrial applications. Disc thickness is maintained between 2.2 to 3.2 mm with a tolerance of ±0.05 mm. The core uses spring steel with a double-layer anti-corrosion coating. The segment bond is a porous cobalt-bronze matrix for rapid heat dissipation. The maximum permissible operating speed is 85 meters per second. This disc is designed for cutting granite with Mohs 7 hardness and porcelain ceramic.

The disc structure features laser-cut wave-shaped gullets to minimize vibration. This pattern reduces operational noise by up to 15 decibels. The number of segments varies from 16 to 36 depending on diameter. Diamond segment height is 7 to 10 mm for extended service life. A nickel-chromium coating on the body prevents rust and material adhesion. The disc balance quality is Grade G 6.3 according to ISO 1940 standards. It delivers optimal performance on wet cut machines with minimum 2200-watt power. Cutting results show clean, chip-free edges with ±0.2 mm accuracy. The discs effective life reaches 3000 linear meters of cutting in granite.You can order and buy ASRON Granite and Ceramic Cutting Disc from Iran by contacting us through whatsaap and email.

WEBSITE: ASRON Granite and Ceramic Cutting Disc Iran

Training for Using the Aseron Ceramic Cutter Machine

For initial setup, place the machine on a flat and stable surface. Connect the water source to the machines inlet port. Fill the water tank to the indicated marker line. Secure the ceramic tile firmly onto the worktable using the dedicated clamps. Mark the cutting line on the piece with a marker. Turn on the machine and gently lower the lever. The diamond blade must move along the cutting line at a uniform speed with gentle pressure. During operation, the flow of cooling water must be continuous. After completing the cut, turn off the machine and let it dry. Clean the blade and moving parts after each use.

Water-Miscible Metalworking Coolant Soluble Oil

.jpg?width=200&height=200&cropratio=200:200&image=/admin/uploads/انواع برقوماشینی ودستی __ابزارجهان برش_1_6_u743_e16449__th (22).jpg&url=/admin/uploads/انواع برقوماشینی ودستی __ابزارجهان برش_1_6_u743_e16449__th (22).jpg)

abzar jahan boresh

Industrial Sharpening Machine with Cooling System

Sharpening Oilstones

Pneumatic Tile and Granite Cutter