rotary group , Iran

- Price :To negotiate

- order by whatsapp

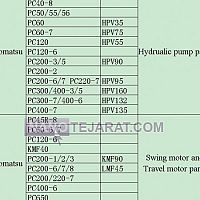

The piston rotor is a critical component in piston pumps and hydraulic motors, converting hydraulic energy into rotary mechanical motion. Typical displacement ranges from 5 to 250 cc per revolution, with operating pressure up to 350 bar. The rotor body is made of hardened steel or resistant alloy, with anti-wear coating and heat treatment to provide high resistance to corrosion and abrasion. Pistons are made of pressure- and temperature-resistant materials, moving precisely in rotor grooves to ensure uniform and vibration-free power transmission.

Structurally, the piston rotor consists of the central rotor body, piston-retaining grooves, movable pistons, sealing rings, and pressure chambers. Precision design of grooves and pistons reduces friction and ensures efficiency above 90%. The rotor can operate at temperatures from -20 to 100°C and withstand heavy vibration and mechanical shock. It is used in hydraulic motors, industrial piston pumps, automotive hydraulic systems, and heavy machinery, with a service life exceeding 100,000 hours.You can order and buy rotary group from Iran by contacting us through whatsaap and email.

WEBSITE: rotary group Iran

Piston Rotor Installation and Startup Procedure

Installing a piston rotor must follow manufacturer instructions and industrial standards to ensure safety and system longevity. First, clean the shaft and rotor housing from contaminants and apply clean hydraulic oil to bearings and contact surfaces. The rotor should be carefully mounted on the shaft, and axial clearance with the casing and pistons must be set according to factory tolerances. After installation, start the system at low pressure and flow to bleed air and detect potential leaks. Finally, gradually increase operating pressure while monitoring smooth operation and noise to ensure optimal performance.