MIG MAG ring welding wire , Iran

- Price :To negotiate

- order by whatsapp

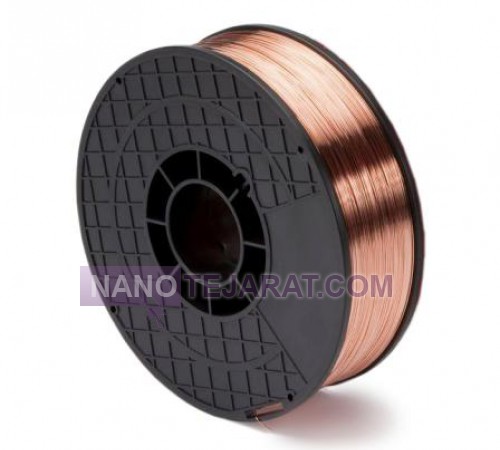

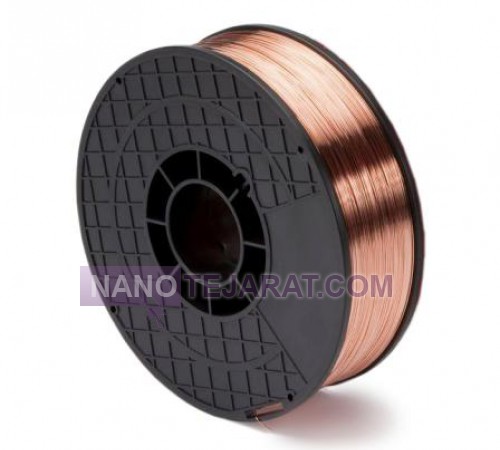

MIG MAG ring welding wire is a key component in semi-automatic welding processes, designed with a uniform structure and industrial-grade engineering to deliver clean and durable welds. Typically made from low-carbon steel, this wire is coated with copper to enhance electrical conductivity and reduce resistance during current flow. Its ring-shaped packaging ensures continuous and smooth wire feeding into welding machines, preventing issues like tangling or uneven wire pull. Available in various diameters such as 0.8, 1.0, and 1.2 mm, the wire features a precise chemical composition that includes alloying elements like silicon and manganese to improve arc stability and weld strength. Its reliable performance in shielding gas environments like argon or argon-CO₂ mixtures, along with high resistance to cracking, makes it an ideal choice for heavy industries, automotive manufacturing, metal structure fabrication, and pressure vessel production.

To buy and inquire about the price of MIG MAG ring welding wire for welding mild steel, please contact the sales unit at Josh o Bores Aria, the specialized store for all types of welding wire, to receive expert consultation and competitive bulk pricing.

You can order and buy MIG MAG ring welding wire from Iran by contacting us through whatsaap and email.

WEBSITE: MIG MAG ring welding wire Iran

Technical and Structural Specifications of MIG MAG Ring Welding Wire

MIG MAG ring welding wire is one of the most widely used consumables in semi-automatic MIG and MAG welding processes. It is engineered with precision and manufactured with a uniform structure to ensure high-quality welds. This type of welding wire is typically packaged in coils or spools and is commonly made from low-carbon steel with a copper coating, which provides excellent electrical conductivity during welding. The ring-shaped design allows for smooth and consistent wire feeding into welding machines, minimizing tangling or uneven pulling. This feature significantly enhances efficiency on industrial production lines and reduces machine downtime.

In terms of technical specifications, MIG MAG ring welding wire is available in various diameters such as 0.8, 1.0, and 1.2 mm, which are selected based on the project type and material thickness. Its chemical composition includes elements like silicon, manganese, and a controlled amount of carbon, all designed to increase weld strength and reduce spatter. Additional structural advantages include easy arc initiation, stable arc performance, and high resistance to cracking. This type of welding wire performs optimally in shielding gas environments such as pure argon or argon mixed with CO₂. It is widely used in automotive manufacturing, steel structures, industrial equipment, and pressure vessel production, demonstrating its versatility and consistent performance.

Solid metal welding wire

BEST ARC ER-5183 Aluminum Welding Rod, 2.4 mm

BEST ARC ER-5356 Aluminum Welding Rod, 4.0 mm

Aluminum welding wire

BEST ARC ER-5183 Aluminum Welding Rod, 3.2 mm

Aluminum Welding Rod ER-5356, 2.4 mm, BEST ARC

-

BEST ARC ER-5183 Aluminum Welding Rod, 4.0 mm

BestaRC ERCUAL-A2 Aluminum Welding Rod, 2.4 mm

BEST ARC ER-5356 Aluminum Welding Rod, 3.2 mm