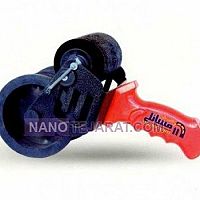

Rapid Mechanical Dating Machine , Iran

The rapid mechanical dating machine is made from CK45 carbon steel alloy via gas nitriding. Impact component surface hardness is enhanced to 70 HRC for extended service life. Operational speed reaches 15 to 20 marks per minute using an energy-storage mechanism. The standard engraved roller diameter is 80 mm with a 25-micron hard chrome coating. It can date-mark metallic materials up to 120 Brinell HB hardness and 2.5 mm thickness. Impression depth is adjustable from 0.15 to 0.7 mm with a line resolution of 0.2 mm.

The machine structure employs a flywheel mechanism with a 1.2 kg rotating mass for kinetic energy storage. The quick-release system is a sliding type with a response time under 0.1 seconds. The date roller is modular, featuring a tool-less quick-change system under 30 seconds. The body is 8 mm thick steel with electrostatic epoxy coating for corrosion resistance. Machine weight is 32 kg with a base dimension of 300 x 250 mm for dynamic stability. It complies with ISO 13849-1 for machinery safety and EN 1032 for controlled vibration.You can order and buy Rapid Mechanical Dating Machine from Iran by contacting us through whatsaap and email.

WEBSITE: Rapid Mechanical Dating Machine Iran

Advantages and Disadvantages of Mechanical vs. Electric Date Coders

Advantages of Mechanical Coders:

Lower purchase and maintenance costs due to simple construction.

Independence from electricity and usability in environments without power access.

Greater resistance to harsh conditions like humidity and dust.

Simpler repairs with standard, readily available mechanical parts.

Disadvantages of Mechanical Coders:

Limited printing speed and incompatibility with high-speed production lines.

Low flexibility in changing printed information requires physical plate change.

Lower print clarity and accuracy compared to electric models.

Operator fatigue during continuous use due to physical effort required.

Advantages of Electric Coders:

High printing speed and accuracy with integration capability into automatic lines.

Full flexibility in programming and instant information changes.

Ability to print complex information like barcodes and graphics.

Reduced operator intervention and increased productivity.

Disadvantages of Electric Coders:

Higher capital investment and repair costs.

Dependence on electricity and sensitivity to voltage fluctuations.

Need for a cleaner work environment and more careful maintenance.

Continuous energy consumption.

The final choice depends on line speed, budget, work environment, and required flexibility.

Packing machine

Manual Plastic Container Sealing Machine

ice cream pillow packing machine

.jpg?width=200&height=200&cropratio=200:200&image=/admin/uploads/دستگاه بسته بندی تک قطعه ای _packing machine _صنایع ماشین سازی مسائلی _5_81_u447_93d3eb__44 (2).jpg&url=/admin/uploads/دستگاه بسته بندی تک قطعه ای _packing machine _صنایع ماشین سازی مسائلی _5_81_u447_93d3eb__44 (2).jpg)

packing machine

pillow packing machine

sandwich flow packing machine

biscuit packing machine

wafer flow packing machine

Industrial Air Curtain

industrial machine