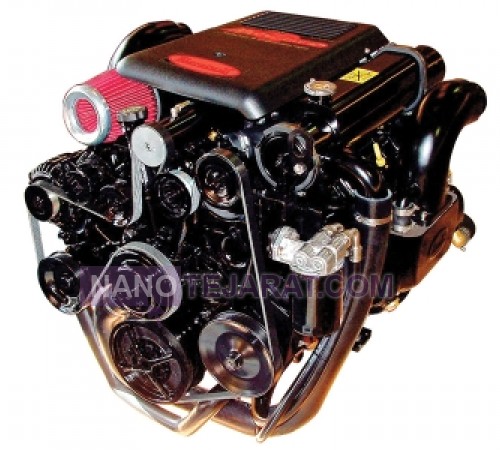

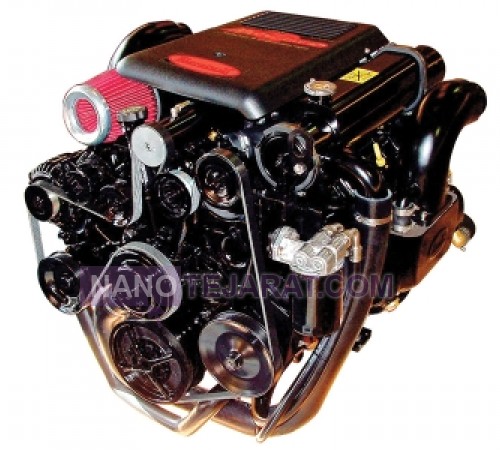

Supercharger maintenance , Iran

Supercharger maintenance involves inspecting and replacing rotors or blades, bearings, seals, and housing to maintain airflow efficiency above 90% and output pressure between 0.5 and 2 bar. Rotor speeds typically range from 20,000 to 60,000 RPM, with airflow capacity from 50 to 500 liters per second. Dynamic rotor balancing must be within 0.02 millimeters, and oil seals, such as NBR or Viton, are replaced to prevent air and oil leakage.

Post-repair performance tests include measuring output pressure, airflow, and operating temperature. Operating temperature should range from 0 to 120°C, with noise levels below 80 dB. Non-destructive testing NDT, including ultrasonic and visual inspection, is performed on bearings and housing. Repairs following ISO 9001 and SAE J1726 standards can extend supercharger service life beyond 15,000 hours.You can order and buy Supercharger maintenance from Iran by contacting us through whatsaap and email.

WEBSITE: Supercharger maintenance Iran