.jpg)

Water Well Drilling Wire Rope , Iran

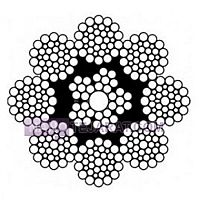

The water well drilling wire rope is a critical tool for raising and lowering equipment and pipes in water wells. It is made from carbon or alloy steel with tensile strength ranging from 1570 to 1960 N/mm². Wire diameters typically range from 12 to 32 mm, with 6x19 or 6x37 constructions used to enhance flexibility and fatigue resistance. Precise and uniform strand twisting ensures proper stress distribution and reduces the risk of failure. Coatings include industrial oil or hot-dip galvanizing to improve corrosion and moisture resistance.

Structurally, the water well drilling wire rope consists of steel strands twisted around a steel or fiber core, providing radial strength and wear resistance. Standard rope lengths range from 50 to 150 meters and can be customized according to well depth. The ropes are designed to withstand temperatures from −40°C to +250°C and harsh, humid, or corrosive environments. This wire rope is used in winches, water well hoists, and industrial load handling equipment, ensuring reliable performance under demanding conditions.You can order and buy Water Well Drilling Wire Rope from Iran by contacting us through whatsaap and email.

WEBSITE: Water Well Drilling Wire Rope Iran

.jpg)

Steel vs. Alloy Steel Drilling Wire Ropes

Drilling wire ropes are manufactured from either standard steel or alloy steel depending on project type and environmental conditions. Standard steel ropes are suitable for light projects and low-stress conditions, offering lower cost but limited tensile strength and durability. Alloy steel drilling ropes, with precise heat treatment, provide very high tensile strength, proper flexibility, and strong dynamic load resistance, ideal for heavy oil, gas, and mining projects. Resistance to wear, metal fatigue, and corrosion extends equipment service life. Proper selection of rope type, diameter, and duty class ensures operational safety and efficiency.